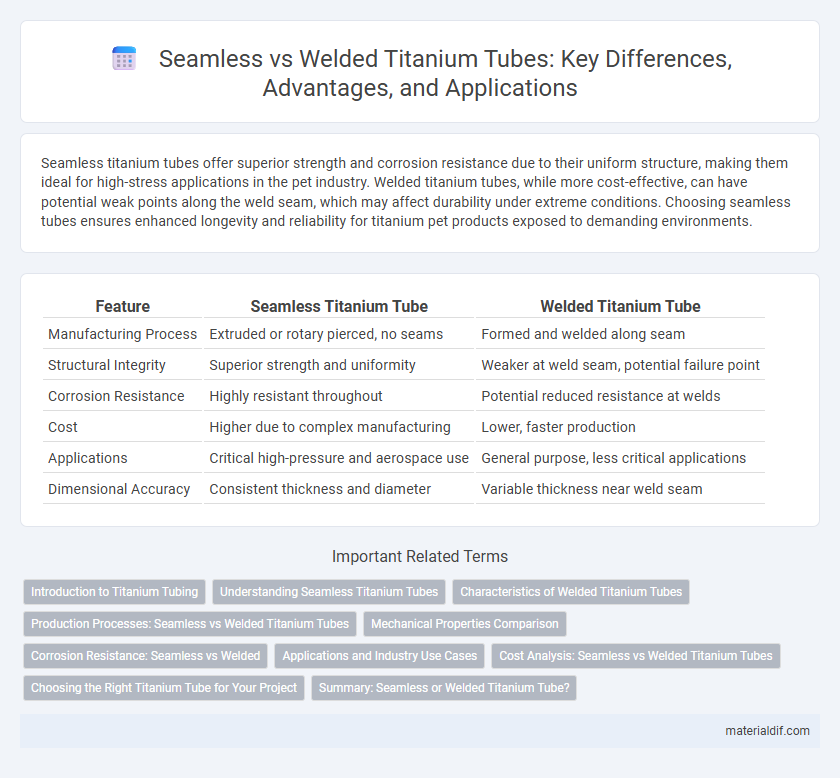

Seamless titanium tubes offer superior strength and corrosion resistance due to their uniform structure, making them ideal for high-stress applications in the pet industry. Welded titanium tubes, while more cost-effective, can have potential weak points along the weld seam, which may affect durability under extreme conditions. Choosing seamless tubes ensures enhanced longevity and reliability for titanium pet products exposed to demanding environments.

Table of Comparison

| Feature | Seamless Titanium Tube | Welded Titanium Tube |

|---|---|---|

| Manufacturing Process | Extruded or rotary pierced, no seams | Formed and welded along seam |

| Structural Integrity | Superior strength and uniformity | Weaker at weld seam, potential failure point |

| Corrosion Resistance | Highly resistant throughout | Potential reduced resistance at welds |

| Cost | Higher due to complex manufacturing | Lower, faster production |

| Applications | Critical high-pressure and aerospace use | General purpose, less critical applications |

| Dimensional Accuracy | Consistent thickness and diameter | Variable thickness near weld seam |

Introduction to Titanium Tubing

Seamless titanium tubes offer superior corrosion resistance and enhanced mechanical strength compared to welded titanium tubes, making them ideal for high-pressure and critical applications in aerospace and medical industries. Welded titanium tubes, produced by rolling and welding titanium sheets, provide cost-effective solutions for less demanding environments while maintaining good corrosion resistance. Understanding the differences in manufacturing processes and structural integrity is essential when selecting the appropriate titanium tubing for specific industrial needs.

Understanding Seamless Titanium Tubes

Seamless titanium tubes offer superior strength and corrosion resistance due to their uniform metal composition without weld joints, enhancing durability in high-pressure and chemically aggressive environments. These tubes are manufactured through hot extrusion or rotary piercing, resulting in a smooth, continuous surface that minimizes the risk of cracks or leaks compared to welded titanium tubes. Their consistent mechanical properties and flawless structure make seamless titanium tubes ideal for critical applications in aerospace, medical devices, and chemical processing industries.

Characteristics of Welded Titanium Tubes

Welded titanium tubes feature a continuous seam created by fusing edges through high-frequency welding, offering precise dimensions and a smooth surface finish. They provide excellent corrosion resistance and high strength-to-weight ratio, making them ideal for applications requiring custom lengths and tight tolerances. Welded tubes are generally more cost-effective for large-diameter or thin-walled tubing compared to seamless tubes, while maintaining durability in aerospace, chemical processing, and medical industries.

Production Processes: Seamless vs Welded Titanium Tubes

Seamless titanium tubes are manufactured through hot extrusion or rotary piercing, creating a single, continuous piece without any welds, which enhances strength and corrosion resistance. Welded titanium tubes are produced by rolling a titanium sheet into a cylindrical shape and then joining the edges via high-frequency welding, allowing for more cost-effective production but potentially introducing weak points along the weld seam. The choice between seamless and welded tubes depends on specific application requirements, with seamless tubes favored for high-pressure environments and welded tubes suitable for less demanding conditions.

Mechanical Properties Comparison

Seamless titanium tubes offer superior mechanical properties compared to welded titanium tubes, including higher tensile strength and better fatigue resistance due to the absence of weld joints, which are potential weak points. The uniform grain structure in seamless tubes enhances their corrosion resistance and ability to withstand high-pressure environments. Welded tubes may exhibit localized hardness variations and reduced ductility around the weld seam, impacting overall durability under mechanical stress.

Corrosion Resistance: Seamless vs Welded

Seamless titanium tubes exhibit superior corrosion resistance compared to welded titanium tubes due to the absence of weld seams that can act as corrosion initiation sites. Welded tubes may develop microstructural inconsistencies and residual stresses along the weld line, increasing susceptibility to localized corrosion such as pitting or crevice corrosion. Industries requiring high-performance corrosion resistance, like aerospace and chemical processing, often prefer seamless titanium tubes to ensure enhanced longevity and reliability in aggressive environments.

Applications and Industry Use Cases

Seamless titanium tubes offer superior strength and corrosion resistance, making them ideal for aerospace, chemical processing, and medical implants where high pressure and stress conditions are prevalent. Welded titanium tubes, while typically more cost-effective, are extensively used in heat exchangers, architectural frameworks, and automotive components where complex shapes and sizes are required. Both types serve critical roles in marine and oil & gas industries due to titanium's biocompatibility and resistance to seawater corrosion.

Cost Analysis: Seamless vs Welded Titanium Tubes

Seamless titanium tubes generally incur higher manufacturing costs due to complex extrusion and drawing processes, leading to superior structural integrity and resistance to pressure. Welded titanium tubes offer a cost-effective alternative with lower production expenses but may contain weld seams that affect mechanical strength and corrosion resistance. Cost analysis must balance material performance requirements against budget constraints, with seamless tubes favored for high-pressure, critical applications despite their premium price.

Choosing the Right Titanium Tube for Your Project

Choosing the right titanium tube depends on project requirements such as strength, corrosion resistance, and budget. Seamless titanium tubes offer superior strength and corrosion resistance due to their uniform structure, making them ideal for aerospace and medical applications. Welded titanium tubes provide cost-effective solutions with customizable sizes, suitable for less critical industries like automotive or chemical processing.

Summary: Seamless or Welded Titanium Tube?

Seamless titanium tubes offer superior corrosion resistance and mechanical strength due to their uniform structure, making them ideal for high-pressure and critical applications. Welded titanium tubes are more cost-effective and suitable for less demanding environments, where slight inconsistencies in the weld joint do not compromise performance. Choosing between seamless and welded titanium tubes depends on specific project requirements, budget constraints, and the intended service conditions.

Seamless Titanium Tube vs Welded Titanium Tube Infographic

materialdif.com

materialdif.com