ASTM B265 and ASTM F67 are both standards for titanium materials, with ASTM B265 primarily covering titanium and titanium alloy sheets, strips, and plates used in structural applications. ASTM F67 specifically addresses unalloyed titanium for surgical implant applications, emphasizing biocompatibility and precise mechanical properties. Choosing between ASTM B265 and ASTM F67 depends on the intended use, with ASTM F67 suited for medical and dental implants, while ASTM B265 is ideal for industrial and aerospace components.

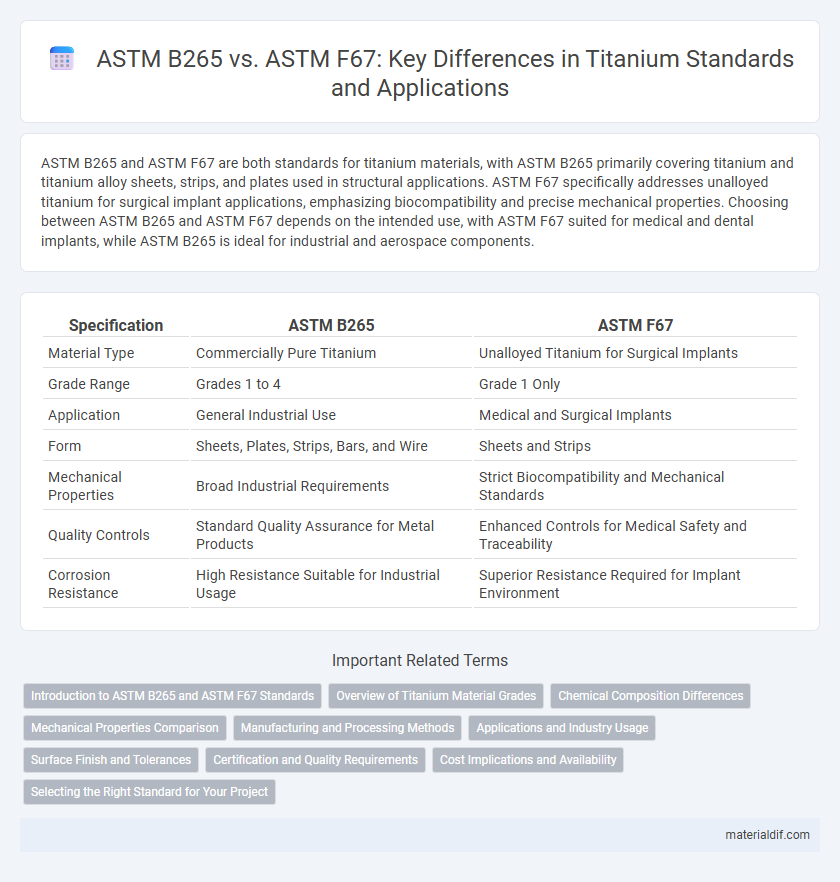

Table of Comparison

| Specification | ASTM B265 | ASTM F67 |

|---|---|---|

| Material Type | Commercially Pure Titanium | Unalloyed Titanium for Surgical Implants |

| Grade Range | Grades 1 to 4 | Grade 1 Only |

| Application | General Industrial Use | Medical and Surgical Implants |

| Form | Sheets, Plates, Strips, Bars, and Wire | Sheets and Strips |

| Mechanical Properties | Broad Industrial Requirements | Strict Biocompatibility and Mechanical Standards |

| Quality Controls | Standard Quality Assurance for Metal Products | Enhanced Controls for Medical Safety and Traceability |

| Corrosion Resistance | High Resistance Suitable for Industrial Usage | Superior Resistance Required for Implant Environment |

Introduction to ASTM B265 and ASTM F67 Standards

ASTM B265 specifies the requirements for titanium and titanium alloy strip, sheet, and plate, emphasizing chemical composition, mechanical properties, and manufacturing processes for aerospace and industrial applications. ASTM F67 outlines the chemical and mechanical standards for unalloyed titanium bars and billets used primarily in medical implant devices and surgical instruments. Both standards ensure high-quality titanium materials but cater to distinct sectors with ASTM B265 focused on structural components and ASTM F67 tailored towards biomedical applications.

Overview of Titanium Material Grades

ASTM B265 specifies the standard specification for titanium and titanium alloy strip, sheet, and plate, primarily covering commercially pure grades such as Grade 1, Grade 2, Grade 3, and Grade 4 known for their excellent corrosion resistance and ductility. ASTM F67 focuses on unalloyed titanium for surgical implant applications, emphasizing Grade 1 and Grade 2 due to their biocompatibility and suitability in medical environments. Both standards define chemical composition and mechanical properties but serve distinct industrial sectors, with ASTM B265 geared towards structural and aerospace uses, while ASTM F67 targets medical implants.

Chemical Composition Differences

ASTM B265 specifies the chemical composition for titanium and titanium alloy mill products, emphasizing commercially pure grades such as Grade 1 to Grade 4 with precise limits on oxygen, nitrogen, carbon, and iron content to ensure ductility and corrosion resistance. ASTM F67 focuses on titanium's chemical composition specifically for surgical implant applications, enforcing stricter impurity limits, especially for oxygen and iron, to enhance biocompatibility and prevent adverse tissue reactions. The primary difference lies in ASTM F67's tighter control on elemental impurities to meet medical standards, whereas ASTM B265 allows broader ranges suitable for industrial uses.

Mechanical Properties Comparison

ASTM B265 specifies requirements for titanium and titanium alloy bars, billets, and billets for forging with emphasis on mechanical properties such as tensile strength, yield strength, and elongation, targeting wrought products. ASTM F67 focuses on unalloyed titanium for surgical implant applications, mandating stringent mechanical property limits to ensure biocompatibility and implant performance, including controlled tensile strength and elongation. Compared to ASTM B265, ASTM F67 generally enforces tighter mechanical property ranges to meet medical device standards, prioritizing reliability and consistency in implant-grade titanium.

Manufacturing and Processing Methods

ASTM B265 covers the standard specification for titanium and titanium alloy strip, sheet, and plate, emphasizing processes like hot rolling, annealing, and pickling to achieve desired mechanical properties. ASTM F67 focuses specifically on unalloyed titanium for surgical implants, highlighting manufacturing methods such as cold working and passivation to ensure biocompatibility and corrosion resistance. The key distinction lies in ASTM B265's broader industrial application with thermal treatments, whereas ASTM F67 centers on precise surface treatments for medical-grade titanium.

Applications and Industry Usage

ASTM B265 covers titanium and titanium alloy plates, sheets, and strips primarily used in aerospace, chemical processing, and marine industries due to its strength and corrosion resistance. ASTM F67 specifically addresses unalloyed titanium for surgical implant applications, emphasizing biocompatibility and purity critical for medical device manufacturing. While ASTM B265 supports structural and industrial uses, ASTM F67 targets healthcare sectors requiring stringent material specifications for patient safety.

Surface Finish and Tolerances

ASTM B265 specifies requirements for titanium and titanium alloy sheets and plates with tighter surface finish standards, typically ranging from 63 to 125 microinches RMS, ensuring a smooth, uniform texture ideal for aerospace and medical applications. ASTM F67 covers titanium and titanium alloy bars and billets with less stringent surface finish criteria, often allowing rougher finishes suitable for forging and machining processes. Tolerance levels in ASTM B265 are more precise, focusing on thickness and flatness for critical application accuracy, whereas ASTM F67 tolerances prioritize material composition and mechanical properties over surface uniformity.

Certification and Quality Requirements

ASTM B265 specifies the standard for titanium and titanium alloy strip, sheet, and plate, emphasizing chemical composition, mechanical properties, and microstructure requirements with stringent certification for aerospace and industrial applications. ASTM F67 focuses on unalloyed titanium for surgical implants, highlighting biocompatibility and traceability, ensuring compliance with rigorous medical-grade quality standards. Both standards mandate thorough testing and documentation, but ASTM F67 requires more specialized certification protocols to meet healthcare industry regulations.

Cost Implications and Availability

ASTM B265 titanium, commonly used for industrial and structural applications, generally has lower cost implications due to broader manufacturing and availability compared to ASTM F67, which is specifically designed for medical implant-grade titanium. The specialized processing and stricter quality control requirements for ASTM F67 make it more expensive and less readily available than ASTM B265. Procurement decisions should weigh the cost premium of ASTM F67 against the criticality of biocompatibility and corrosion resistance needed for medical applications.

Selecting the Right Standard for Your Project

ASTM B265 and ASTM F67 are critical standards for selecting titanium in industrial applications, with B265 focusing on titanium and titanium alloy sheet, strip, plate, and razor blade quality, while ASTM F67 targets unalloyed titanium for surgical implant applications. The choice between these depends on project requirements such as corrosion resistance, mechanical strength, and biocompatibility, with ASTM F67 preferred in medical fields due to its strict purity and composition criteria. Understanding the specific properties and manufacturing focus of each standard ensures optimal material performance and regulatory compliance for your titanium project.

ASTM B265 vs ASTM F67 Infographic

materialdif.com

materialdif.com