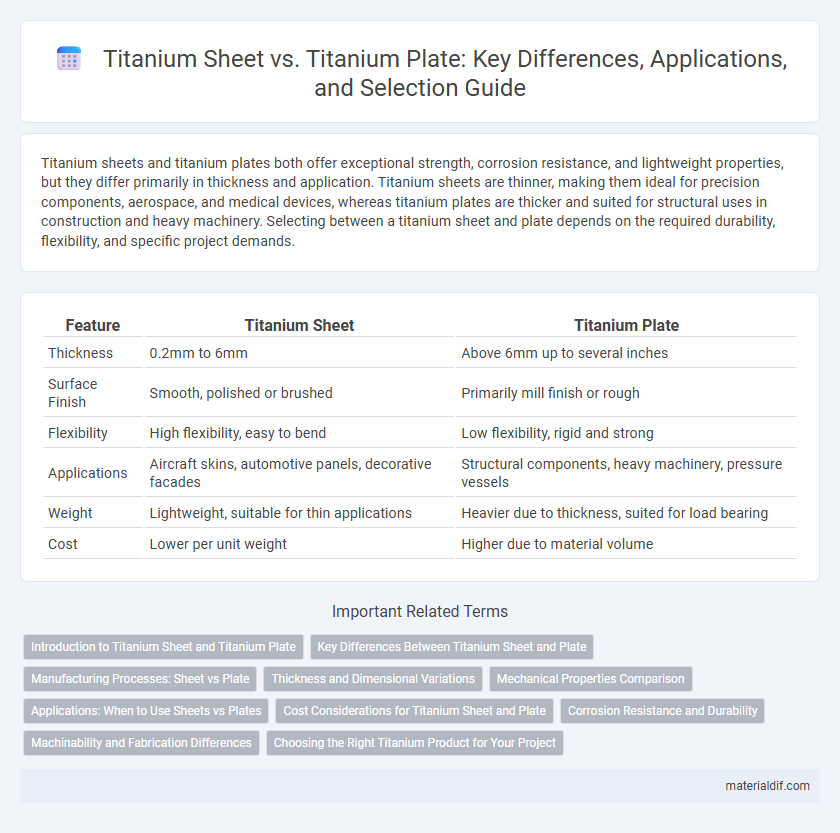

Titanium sheets and titanium plates both offer exceptional strength, corrosion resistance, and lightweight properties, but they differ primarily in thickness and application. Titanium sheets are thinner, making them ideal for precision components, aerospace, and medical devices, whereas titanium plates are thicker and suited for structural uses in construction and heavy machinery. Selecting between a titanium sheet and plate depends on the required durability, flexibility, and specific project demands.

Table of Comparison

| Feature | Titanium Sheet | Titanium Plate |

|---|---|---|

| Thickness | 0.2mm to 6mm | Above 6mm up to several inches |

| Surface Finish | Smooth, polished or brushed | Primarily mill finish or rough |

| Flexibility | High flexibility, easy to bend | Low flexibility, rigid and strong |

| Applications | Aircraft skins, automotive panels, decorative facades | Structural components, heavy machinery, pressure vessels |

| Weight | Lightweight, suitable for thin applications | Heavier due to thickness, suited for load bearing |

| Cost | Lower per unit weight | Higher due to material volume |

Introduction to Titanium Sheet and Titanium Plate

Titanium sheet and titanium plate differ primarily in thickness and application, with sheets typically measuring less than 6mm and plates exceeding this thickness. Both are fabricated from titanium alloys known for outstanding strength-to-weight ratios, corrosion resistance, and biocompatibility. Common uses include aerospace, automotive, medical implants, and chemical processing industries where durability and lightweight properties are essential.

Key Differences Between Titanium Sheet and Plate

Titanium sheets are thinner, typically less than 6 mm in thickness, making them suitable for applications requiring flexibility and lightweight properties, such as aerospace cladding and automotive body panels. Titanium plates are thicker, often exceeding 6 mm, providing greater structural strength for heavy-duty applications like shipbuilding, pressure vessels, and industrial machinery components. The manufacturing processes also differ, with sheets produced through rolling and plates often requiring additional forging or heat treatment for enhanced durability.

Manufacturing Processes: Sheet vs Plate

Titanium sheets are produced through rolling processes that use thinner slabs, resulting in fine grain structure and uniform thickness ideal for precision applications. Titanium plates undergo hot or cold rolling with thicker initial slabs, leading to greater thickness and higher strength suited for heavy-duty structural uses. Both manufacturing methods ensure corrosion resistance and high strength-to-weight ratio, but differ mainly in processing parameters tailored to final dimensional and mechanical requirements.

Thickness and Dimensional Variations

Titanium sheets typically range from 0.2 mm to 6 mm in thickness, offering uniformity and consistent surface finishes ideal for precision applications. Titanium plates generally exceed 6 mm in thickness, with dimensional variations accommodating structural uses requiring strength and durability. The choice between sheet and plate depends on specific project requirements, balancing thickness tolerance and mechanical properties.

Mechanical Properties Comparison

Titanium sheets typically offer superior flexibility and are thinner, making them ideal for applications requiring lightweight and corrosion-resistant materials with moderate strength. Titanium plates exhibit higher thickness and enhanced mechanical properties such as increased tensile strength and hardness, suitable for heavy-duty structural components. The choice between titanium sheet and plate depends on the specific mechanical property requirements, including yield strength, elongation, and impact resistance.

Applications: When to Use Sheets vs Plates

Titanium sheets are ideal for aerospace and automotive components requiring lightweight, corrosion-resistant materials with precise thickness and smooth surfaces. Titanium plates are better suited for structural applications such as marine equipment, pressure vessels, and heavy machinery where thicker, more robust durability is essential. Choosing between sheets and plates depends on the required material thickness, mechanical strength, and specific industry application.

Cost Considerations for Titanium Sheet and Plate

Titanium sheets generally cost less than titanium plates due to thinner dimensions and lower material volume, making them more economical for applications requiring lightweight components. Titanium plates involve higher manufacturing expenses from increased thickness and machining complexity, leading to a higher overall price. Budget-sensitive projects prioritize titanium sheets, while titanium plates justify their cost with enhanced structural strength and durability.

Corrosion Resistance and Durability

Titanium sheets and plates both exhibit exceptional corrosion resistance, making them ideal for harsh environments such as marine and chemical processing industries. Titanium plates, being thicker, offer enhanced durability and structural strength compared to thinner titanium sheets, which are better suited for applications requiring flexibility and lightweight properties. The superior corrosion resistance of titanium arises from its stable oxide layer, which protects both sheets and plates from oxidizing and deteriorating over time.

Machinability and Fabrication Differences

Titanium sheets offer superior machinability due to their thinner profile, allowing for precise cutting, bending, and forming with less tool wear and lower power consumption compared to thicker titanium plates. Titanium plates, being thicker and denser, require more robust machining equipment and slower feed rates to prevent tool damage and ensure accuracy, making them less adaptable in fabrication processes. Fabricators often prefer titanium sheets for intricate designs and lightweight applications, while titanium plates are chosen for heavy-duty structural components demanding higher strength and durability.

Choosing the Right Titanium Product for Your Project

Titanium sheets provide a uniform thickness and smooth surface, making them ideal for applications requiring precise dimensions and lightweight solutions such as aerospace panels and automotive body parts. Titanium plates, being thicker and more robust, are suited for heavy-duty structural components, marine applications, and industrial machinery that demand superior strength and durability. Selecting the right titanium product depends on project requirements including thickness, strength, weight, and corrosion resistance, with sheets favored for flexibility and plates for high-load performance.

Titanium Sheet vs Titanium Plate Infographic

materialdif.com

materialdif.com