Rolling Titanium pet sheets enhances surface finish and mechanical properties by compressing and elongating the material, resulting in a smoother texture and improved strength. Extrusion shapes Titanium pet by forcing molten metal through a die, allowing for complex cross-sectional profiles but often producing a rougher surface requiring further processing. Choosing between rolling and extrusion depends on the desired product characteristics, with rolling favored for precision and finish, while extrusion excels in creating intricate shapes.

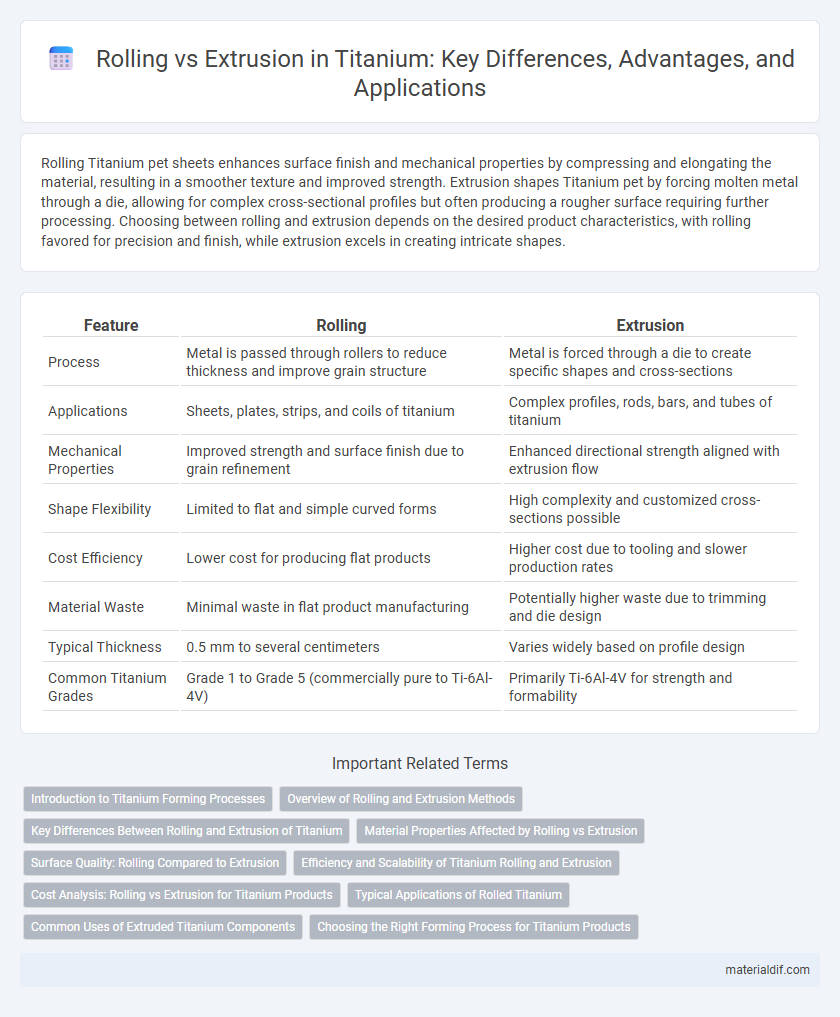

Table of Comparison

| Feature | Rolling | Extrusion |

|---|---|---|

| Process | Metal is passed through rollers to reduce thickness and improve grain structure | Metal is forced through a die to create specific shapes and cross-sections |

| Applications | Sheets, plates, strips, and coils of titanium | Complex profiles, rods, bars, and tubes of titanium |

| Mechanical Properties | Improved strength and surface finish due to grain refinement | Enhanced directional strength aligned with extrusion flow |

| Shape Flexibility | Limited to flat and simple curved forms | High complexity and customized cross-sections possible |

| Cost Efficiency | Lower cost for producing flat products | Higher cost due to tooling and slower production rates |

| Material Waste | Minimal waste in flat product manufacturing | Potentially higher waste due to trimming and die design |

| Typical Thickness | 0.5 mm to several centimeters | Varies widely based on profile design |

| Common Titanium Grades | Grade 1 to Grade 5 (commercially pure to Ti-6Al-4V) | Primarily Ti-6Al-4V for strength and formability |

Introduction to Titanium Forming Processes

Rolling and extrusion are two primary titanium forming processes used to shape titanium alloys into useful products. Rolling involves compressing titanium between rollers to reduce thickness and improve mechanical properties, while extrusion forces titanium billets through a die to create complex cross-sectional shapes with enhanced structural integrity. Both methods optimize titanium's strength-to-weight ratio and corrosion resistance, making them essential for aerospace and medical applications.

Overview of Rolling and Extrusion Methods

Rolling titanium involves passing metal through rollers to achieve uniform thickness and improved surface finish, making it ideal for producing sheets and plates with high strength and consistent mechanical properties. Extrusion pushes heated titanium billets through a shaped die, enabling the creation of complex cross-sectional profiles such as rods and tubes with excellent structural integrity and isotropic grain flow. Both methods are critical in aerospace and medical industries, where precise dimensional control and material performance are paramount.

Key Differences Between Rolling and Extrusion of Titanium

Rolling titanium involves passing the metal through rollers to reduce thickness and improve surface finish, resulting in sheets or plates with uniform mechanical properties. Extrusion forces titanium through a shaped die to create complex cross-sectional profiles, offering greater design flexibility but typically higher production costs. Rolling is preferred for flat products with consistent strength, while extrusion excels in producing intricate shapes used in aerospace and medical applications.

Material Properties Affected by Rolling vs Extrusion

Rolling titanium enhances its grain structure alignment, resulting in improved strength and fatigue resistance along the rolled direction, while extrusion typically promotes uniform grain refinement and isotropic mechanical properties. Rolled titanium exhibits directional anisotropy with higher tensile strength and hardness perpendicular to the rolling direction, whereas extruded titanium shows more consistent ductility and toughness across multiple directions. These differences in microstructural evolution affect the suitability of titanium components for applications requiring specific mechanical performance and formability.

Surface Quality: Rolling Compared to Extrusion

Rolling titanium produces a smoother, more uniform surface finish compared to extrusion, which often results in a rougher texture due to material flow inconsistencies. The controlled deformation in rolling tightens the grain structure, enhancing surface quality and reducing the need for extensive post-processing. Extrusion can lead to surface defects like streaks or die lines, making rolling the preferred method for applications requiring superior surface aesthetics and precision.

Efficiency and Scalability of Titanium Rolling and Extrusion

Titanium rolling offers superior efficiency for producing thin, uniform sheets with excellent mechanical properties, making it ideal for large-scale applications like aerospace cladding and automotive panels. Extrusion provides greater scalability for complex cross-sectional shapes, enabling the production of structural components with enhanced strength and durability in industries such as construction and medical implants. Both processes leverage titanium's corrosion resistance and strength-to-weight ratio, but rolling excels in high-volume flat products while extrusion suits customized, high-precision profiles.

Cost Analysis: Rolling vs Extrusion for Titanium Products

Cost analysis of titanium products reveals rolling processes generally offer lower production expenses due to higher throughput and less complex tooling compared to extrusion. Rolling reduces energy consumption and material waste by enabling continuous sheet production, making it more cost-effective for large-scale manufacturing. Extrusion involves higher operational costs attributed to slower cycle times and increased tooling maintenance, rendering it preferable mainly for specialized shapes and lower volume runs.

Typical Applications of Rolled Titanium

Rolled titanium is typically used in aerospace components such as aircraft skins, fuselage structures, and engine parts due to its superior strength-to-weight ratio and excellent fatigue resistance. Its uniform thickness and smooth surface finish make it ideal for applications requiring precision and durability, including medical implants and military armor plating. Rolled titanium sheets and plates also find extensive use in industrial sectors for heat exchangers, chemical processing equipment, and marine hardware.

Common Uses of Extruded Titanium Components

Extruded titanium components are widely used in aerospace applications due to their high strength-to-weight ratio and corrosion resistance, making them ideal for structural frames, aircraft fittings, and engine components. In the medical industry, extruded titanium is preferred for surgical instruments and implantable devices because of its biocompatibility and precise dimensional control. Industrial uses include chemical processing equipment and heat exchangers where durability and resistance to harsh environments are critical.

Choosing the Right Forming Process for Titanium Products

Rolling titanium offers superior surface finish and dimensional accuracy, making it ideal for thin sheets and plates used in aerospace and medical industries. Extrusion excels in producing complex cross-sectional profiles and long lengths with uniform mechanical properties, suitable for structural components and tubing. Selecting the right forming process depends on the final application requirements, material thickness, and desired mechanical performance.

Rolling vs Extrusion Infographic

materialdif.com

materialdif.com