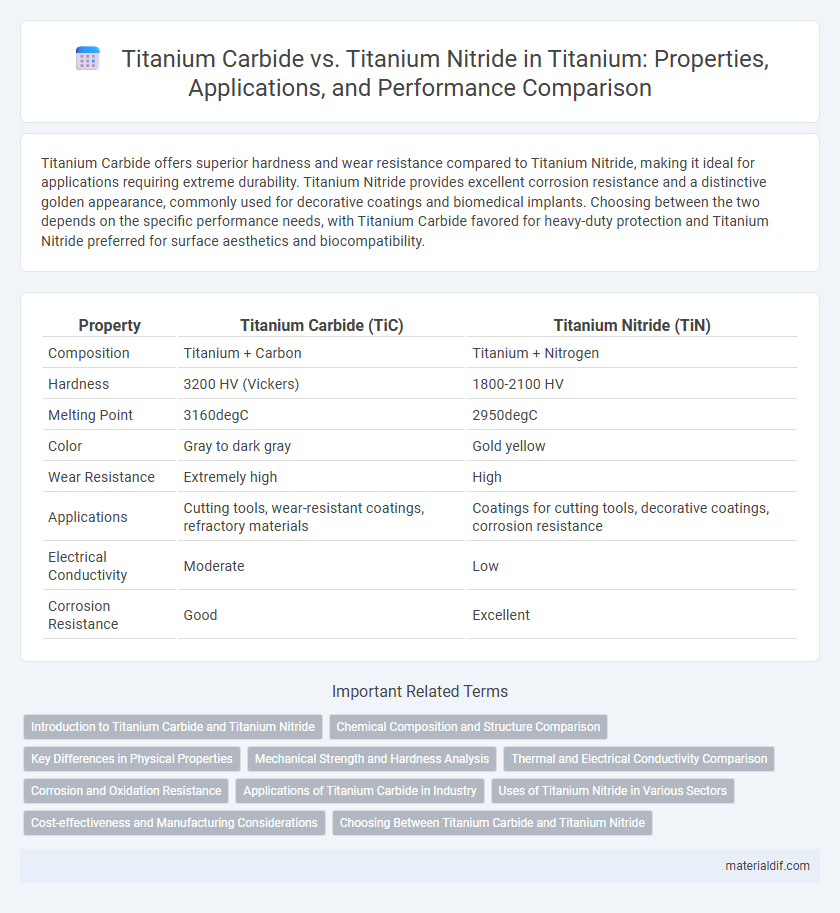

Titanium Carbide offers superior hardness and wear resistance compared to Titanium Nitride, making it ideal for applications requiring extreme durability. Titanium Nitride provides excellent corrosion resistance and a distinctive golden appearance, commonly used for decorative coatings and biomedical implants. Choosing between the two depends on the specific performance needs, with Titanium Carbide favored for heavy-duty protection and Titanium Nitride preferred for surface aesthetics and biocompatibility.

Table of Comparison

| Property | Titanium Carbide (TiC) | Titanium Nitride (TiN) |

|---|---|---|

| Composition | Titanium + Carbon | Titanium + Nitrogen |

| Hardness | 3200 HV (Vickers) | 1800-2100 HV |

| Melting Point | 3160degC | 2950degC |

| Color | Gray to dark gray | Gold yellow |

| Wear Resistance | Extremely high | High |

| Applications | Cutting tools, wear-resistant coatings, refractory materials | Coatings for cutting tools, decorative coatings, corrosion resistance |

| Electrical Conductivity | Moderate | Low |

| Corrosion Resistance | Good | Excellent |

Introduction to Titanium Carbide and Titanium Nitride

Titanium Carbide (TiC) and Titanium Nitride (TiN) are advanced ceramic coatings widely used for enhancing surface hardness and wear resistance in cutting tools and industrial applications. Titanium Carbide exhibits exceptional hardness and high melting point, making it ideal for heavy-duty machining, while Titanium Nitride offers superior corrosion resistance and a lower friction coefficient, often used for decorative purposes and protective coatings. Both materials improve tool life and performance, but TiC excels in extreme mechanical stresses, whereas TiN provides enhanced oxidation stability and aesthetic appeal.

Chemical Composition and Structure Comparison

Titanium Carbide (TiC) consists of titanium and carbon atoms arranged in a face-centered cubic crystal structure, offering high hardness and excellent wear resistance due to strong covalent bonding. Titanium Nitride (TiN) features titanium and nitrogen atoms with a similar face-centered cubic lattice but differs in electronic properties and thermal stability because of the distinct nature of Ti-N bonds. The chemical composition and bonding differences between TiC and TiN significantly influence their mechanical properties and applications in cutting tools and protective coatings.

Key Differences in Physical Properties

Titanium Carbide (TiC) has a higher hardness rating of around 9-9.5 on the Mohs scale compared to Titanium Nitride's (TiN) hardness of about 8-8.5, making TiC more suitable for wear-resistant applications. TiC exhibits a higher melting point, approximately 3,160degC, whereas TiN melts at around 2,930degC, indicating greater thermal stability for TiC in extreme environments. TiN typically has a gold coloration and excellent electrical conductivity, while TiC appears grayish and is less conductive, influencing their use in coating and electronic applications.

Mechanical Strength and Hardness Analysis

Titanium Carbide exhibits superior mechanical strength and hardness compared to Titanium Nitride, making it ideal for cutting tools and wear-resistant coatings in extreme conditions. Its hardness ranges between 2800-3200 HV, significantly higher than Titanium Nitride's typical hardness of 1800-2100 HV. The ceramic nature of Titanium Carbide enhances its resistance to deformation and abrasion, while Titanium Nitride offers better toughness but lower hardness in industrial applications.

Thermal and Electrical Conductivity Comparison

Titanium Carbide exhibits higher thermal conductivity, typically around 21-50 W/m*K, compared to Titanium Nitride's lower range of approximately 20-30 W/m*K, making TiC more effective in heat dissipation applications. In contrast, Titanium Nitride, with its metallic conductivity, demonstrates better electrical conductivity ranging from 2.5 to 3.5 x 10^6 S/m, whereas Titanium Carbide shows moderate electrical conductivity usually an order of magnitude lower. These differences impact their suitability in electronic coatings, where TiN is preferred for electrical contacts and TiC excels in thermal management.

Corrosion and Oxidation Resistance

Titanium Carbide exhibits superior corrosion resistance in acidic environments due to its stable carbide bonds, while Titanium Nitride offers excellent oxidation resistance at high temperatures owing to its dense nitride layer. Titanium Nitride forms a protective oxide film that significantly slows down further oxidation, making it ideal for applications exposed to oxidative conditions. In contrast, Titanium Carbide's hardness and chemical stability make it more suitable for environments prone to chemical corrosion rather than high-temperature oxidation.

Applications of Titanium Carbide in Industry

Titanium Carbide (TiC) is extensively used in cutting tools, wear-resistant coatings, and hard metal composites due to its exceptional hardness and high melting point. Its applications span industries such as aerospace, automotive, and tooling, where durability under extreme conditions is crucial. Titanium Carbide enhances the lifespan and performance of drills, milling cutters, and machining tools in heavy-duty manufacturing environments.

Uses of Titanium Nitride in Various Sectors

Titanium Nitride (TiN) is widely utilized as a hard coating in cutting tools, enhancing wear resistance and tool life across the manufacturing industry. Its biocompatibility makes it ideal for medical implants and surgical instruments, promoting durability and tissue compatibility. In electronics, TiN serves as a conductive barrier layer in semiconductor devices, improving performance and longevity.

Cost-effectiveness and Manufacturing Considerations

Titanium Carbide offers higher wear resistance and hardness compared to Titanium Nitride, making it more suitable for heavy-duty cutting tools despite its higher production cost. Titanium Nitride provides excellent corrosion resistance and is easier to apply via physical vapor deposition, resulting in lower manufacturing expenses and faster production cycles. Cost-effectiveness depends on the specific application: Titanium Nitride is preferred for general-purpose coatings while Titanium Carbide is cost-effective for extended tool life in demanding industrial environments.

Choosing Between Titanium Carbide and Titanium Nitride

Choosing between Titanium Carbide and Titanium Nitride depends on the application's hardness and wear resistance requirements; Titanium Carbide offers superior hardness and abrasion resistance ideal for cutting tools and wear parts, while Titanium Nitride provides excellent corrosion resistance and a smoother surface finish commonly used for protective coatings and decorative purposes. Titanium Carbide exhibits a higher melting point around 3,160degC compared to Titanium Nitride's 2,930degC, influencing thermal stability in high-temperature environments. Cost-effectiveness and ease of deposition also play critical roles, with Titanium Nitride being more cost-efficient for large-scale coating applications due to simpler chemical vapor deposition processes.

Titanium Carbide vs Titanium Nitride Infographic

materialdif.com

materialdif.com