ELI Titanium, also known as Grade 23, offers superior biocompatibility and enhanced corrosion resistance compared to Standard Titanium (Grade 2), making it ideal for medical implants and high-performance applications. Its lower oxygen and iron content result in improved ductility and fracture toughness, ensuring greater durability and reliability under stress. These properties distinguish ELI Titanium as the preferred choice in environments demanding high strength-to-weight ratios and exceptional material purity.

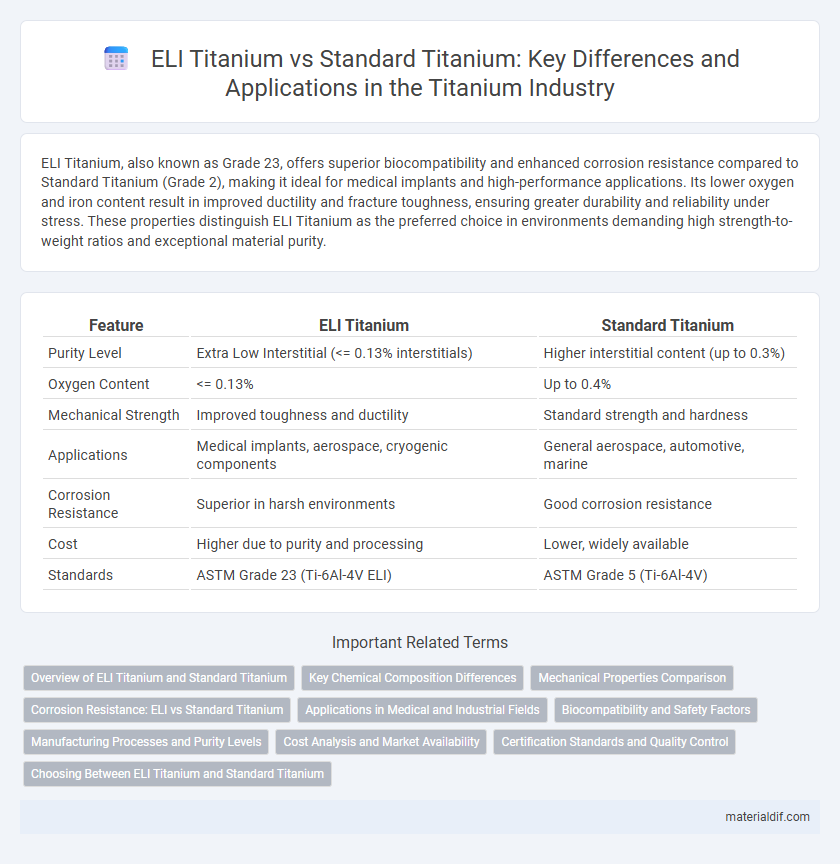

Table of Comparison

| Feature | ELI Titanium | Standard Titanium |

|---|---|---|

| Purity Level | Extra Low Interstitial (<= 0.13% interstitials) | Higher interstitial content (up to 0.3%) |

| Oxygen Content | <= 0.13% | Up to 0.4% |

| Mechanical Strength | Improved toughness and ductility | Standard strength and hardness |

| Applications | Medical implants, aerospace, cryogenic components | General aerospace, automotive, marine |

| Corrosion Resistance | Superior in harsh environments | Good corrosion resistance |

| Cost | Higher due to purity and processing | Lower, widely available |

| Standards | ASTM Grade 23 (Ti-6Al-4V ELI) | ASTM Grade 5 (Ti-6Al-4V) |

Overview of ELI Titanium and Standard Titanium

ELI Titanium, known as Extra Low Interstitial titanium, contains significantly lower levels of interstitial elements such as oxygen, nitrogen, and carbon compared to Standard Titanium, enhancing its toughness and lowering the risk of embrittlement. Standard Titanium, characterized by higher interstitial content, offers excellent strength and corrosion resistance suitable for general structural applications but lacks the superior biocompatibility and fracture resistance of ELI grades. The distinct microstructural differences between ELI and Standard Titanium result in varied mechanical properties and performance, making ELI Titanium ideal for critical aerospace and medical implants where enhanced ductility and purity are paramount.

Key Chemical Composition Differences

ELI Titanium, or Extra Low Interstitial Titanium, contains significantly reduced levels of interstitial elements such as oxygen, nitrogen, and carbon compared to standard titanium grades. This chemical composition enhances its purity and improves properties like fracture toughness and ductility, making it ideal for critical aerospace and medical applications. Standard titanium typically has higher interstitial content, which can increase strength but may compromise performance in environments requiring high corrosion resistance and fatigue strength.

Mechanical Properties Comparison

ELI (Extra Low Interstitial) titanium exhibits superior mechanical properties compared to standard titanium, including higher tensile strength and improved fracture toughness. The reduced interstitial elements in ELI titanium result in enhanced ductility and better fatigue resistance, making it suitable for critical applications like aerospace and medical implants. Standard titanium typically offers good strength but lacks the enhanced mechanical reliability found in ELI grades.

Corrosion Resistance: ELI vs Standard Titanium

ELI titanium exhibits superior corrosion resistance compared to standard titanium due to its lower oxygen content, which enhances its purity and reduces the likelihood of corrosion in aggressive environments. In marine, chemical, and biomedical applications, ELI titanium offers increased durability and longevity by resisting pitting and crevice corrosion more effectively than standard grades. This enhanced resistance makes ELI titanium especially suitable for critical applications requiring exceptional performance in corrosive conditions.

Applications in Medical and Industrial Fields

ELI Titanium, characterized by its extra low interstitial elements such as oxygen and nitrogen, offers superior biocompatibility and enhanced corrosion resistance, making it ideal for medical implants and surgical instruments. In industrial applications, Standard Titanium provides excellent strength and corrosion resistance suitable for aerospace and marine environments, but ELI Titanium's improved ductility and fracture toughness are preferred for critical components subjected to extreme stress. Medical fields prioritize ELI Titanium for prosthetics and dental implants due to its purity and reduced risk of allergic reactions, while industrial sectors utilize Standard Titanium for cost-effective structural and chemical processing equipment.

Biocompatibility and Safety Factors

ELI Titanium, also known as Extra Low Interstitial Titanium, offers superior biocompatibility compared to standard titanium due to its reduced levels of oxygen, nitrogen, carbon, and iron. This enhanced purity minimizes the risk of allergic reactions and inflammatory responses, making ELI Titanium ideal for critical medical implants such as orthopedic and dental devices. Safety factors are significantly improved with ELI Titanium, ensuring greater structural integrity and longevity under physiological conditions.

Manufacturing Processes and Purity Levels

ELI Titanium, or Extra Low Interstitial Titanium, undergoes advanced manufacturing processes to reduce interstitial elements such as oxygen, nitrogen, and carbon to extremely low levels, ensuring superior purity compared to standard titanium. This enhanced purity results in improved mechanical properties, increased fracture toughness, and better performance in critical aerospace and medical applications. Standard titanium typically contains higher interstitial content due to conventional melting and refining methods, which can limit its use in high-stress or highly corrosive environments.

Cost Analysis and Market Availability

ELI Titanium (Extra-Low Interstitial) typically costs 20-30% more than standard titanium due to its enhanced purity and superior mechanical properties suited for aerospace and medical applications. Market availability of ELI Titanium is more limited, with supply concentrated among specialized manufacturers, whereas standard titanium enjoys broader availability and lower lead times across industrial sectors. Cost analysis reveals that while ELI Titanium demands a higher upfront investment, its performance advantages justify the premium in critical, high-performance environments.

Certification Standards and Quality Control

ELI Titanium, known as Extra Low Interstitial Titanium, undergoes stricter certification standards compared to standard titanium, meeting ASTM F136 and ISO 5832-2 requirements for enhanced biocompatibility in medical implants. Quality control for ELI Titanium includes rigorous testing for interstitial elements such as oxygen, nitrogen, carbon, and iron to ensure purity and mechanical properties crucial for aerospace and biomedical applications. Standard titanium follows ASTM B265 with broader tolerances, making ELI Titanium the preferred choice when superior material consistency and certification conformity are essential.

Choosing Between ELI Titanium and Standard Titanium

ELI Titanium, or Extra Low Interstitial Titanium, offers superior fatigue resistance and fracture toughness compared to Standard Titanium, making it ideal for critical medical implants and aerospace components. Standard Titanium provides excellent strength and corrosion resistance but lacks the enhanced purity and ductility found in ELI grades. Choosing between ELI Titanium and Standard Titanium depends on the application's mechanical stress requirements and the need for biocompatibility or extreme reliability.

ELI Titanium vs Standard Titanium Infographic

materialdif.com

materialdif.com