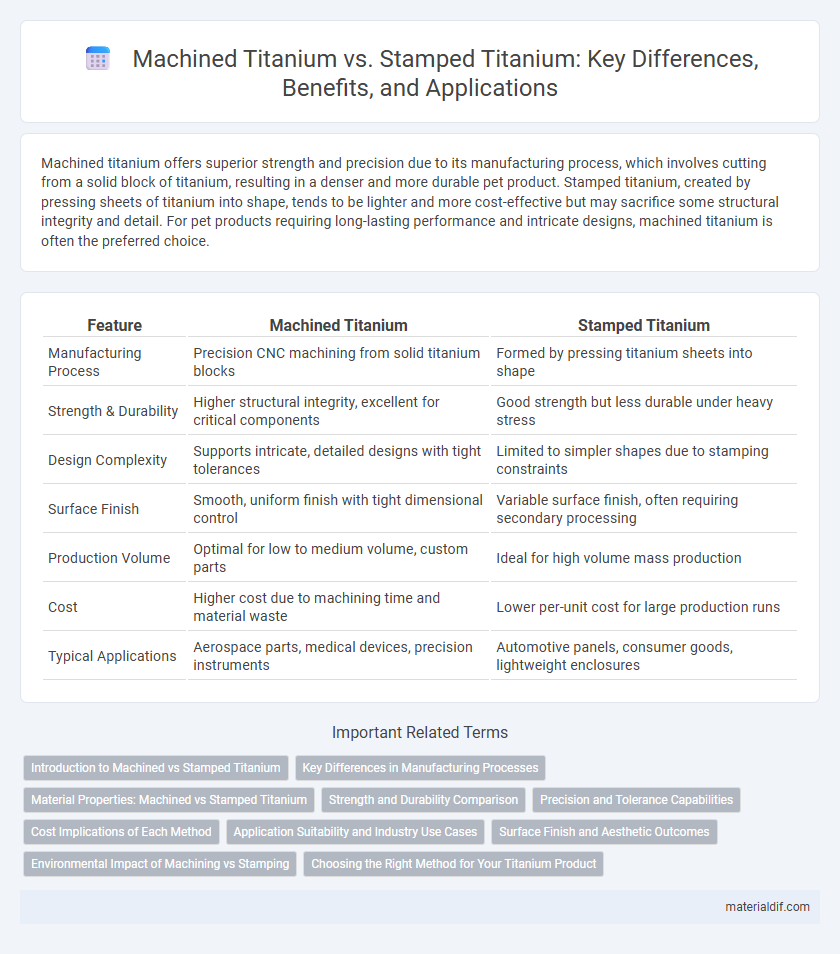

Machined titanium offers superior strength and precision due to its manufacturing process, which involves cutting from a solid block of titanium, resulting in a denser and more durable pet product. Stamped titanium, created by pressing sheets of titanium into shape, tends to be lighter and more cost-effective but may sacrifice some structural integrity and detail. For pet products requiring long-lasting performance and intricate designs, machined titanium is often the preferred choice.

Table of Comparison

| Feature | Machined Titanium | Stamped Titanium |

|---|---|---|

| Manufacturing Process | Precision CNC machining from solid titanium blocks | Formed by pressing titanium sheets into shape |

| Strength & Durability | Higher structural integrity, excellent for critical components | Good strength but less durable under heavy stress |

| Design Complexity | Supports intricate, detailed designs with tight tolerances | Limited to simpler shapes due to stamping constraints |

| Surface Finish | Smooth, uniform finish with tight dimensional control | Variable surface finish, often requiring secondary processing |

| Production Volume | Optimal for low to medium volume, custom parts | Ideal for high volume mass production |

| Cost | Higher cost due to machining time and material waste | Lower per-unit cost for large production runs |

| Typical Applications | Aerospace parts, medical devices, precision instruments | Automotive panels, consumer goods, lightweight enclosures |

Introduction to Machined vs Stamped Titanium

Machined titanium involves precision cutting from solid billets, offering superior strength and intricate detail ideal for aerospace and medical applications. Stamped titanium is produced through high-pressure forming of thin sheets, enabling faster mass production at lower costs with slightly reduced mechanical properties. Understanding these manufacturing methods highlights essential trade-offs in durability, design complexity, and cost-efficiency for titanium components.

Key Differences in Manufacturing Processes

Machined titanium involves precision cutting from a solid titanium block using CNC machines, resulting in highly accurate, detailed, and customizable parts with superior strength and durability. Stamped titanium is produced by pressing thin sheets of titanium into shape with dies, enabling faster mass production but often yielding less intricate and slightly weaker components. The key difference lies in machining's subtractive, highly controlled process versus stamping's faster, form-based shaping from thin material.

Material Properties: Machined vs Stamped Titanium

Machined titanium exhibits superior strength and dimensional accuracy compared to stamped titanium, due to its fabrication process which preserves the metal's natural grain structure and mechanical properties. Stamped titanium often undergoes deformation and strain hardening that can reduce its ductility and fatigue resistance, making it less suitable for high-stress applications. The inherent material integrity in machined titanium results in enhanced corrosion resistance and a longer service life in demanding environments.

Strength and Durability Comparison

Machined titanium components exhibit superior strength and durability compared to stamped titanium due to the precise removal of material maintaining the alloy's original grain structure and mechanical properties. Stamped titanium often undergoes deformation that can introduce stress concentrators, reducing fatigue resistance and overall robustness. Consequently, machined titanium is preferred for high-performance applications requiring maximum structural integrity and long-term reliability.

Precision and Tolerance Capabilities

Machined titanium offers superior precision and tighter tolerance capabilities compared to stamped titanium due to its controlled subtractive manufacturing process, enabling intricate geometries and fine details. CNC machining allows for tolerances as tight as +-0.001 inches, making it ideal for aerospace and medical applications requiring high dimensional accuracy. In contrast, stamped titanium, typically used for high-volume production, has broader tolerances around +-0.005 inches and may exhibit variability due to metal deformation during stamping.

Cost Implications of Each Method

Machined titanium involves precision cutting from solid billets, resulting in higher material waste and longer production times, which significantly increases manufacturing costs compared to stamped titanium. Stamped titanium uses metal sheets shaped through die presses, enabling faster production with less waste but limiting the complexity and thickness of parts that can be created economically. The choice between these methods largely depends on the required precision and volume, with machined titanium favored for low-volume, high-complexity parts, and stamped titanium preferred for high-volume, simpler components due to its cost efficiency.

Application Suitability and Industry Use Cases

Machined titanium offers superior precision and strength, making it ideal for aerospace components, medical implants, and high-performance automotive parts where exact tolerances are critical. Stamped titanium is cost-effective for producing large volumes of thinner, less complex parts, commonly used in consumer electronics, sports equipment, and architectural panels. Industries requiring custom, durable, and high-strength parts prefer machining, while stamped titanium suits applications demanding efficient mass production of lightweight components.

Surface Finish and Aesthetic Outcomes

Machined titanium offers superior surface finish with precise, smooth contours and enhanced aesthetic appeal due to computer-controlled cutting processes that minimize imperfections. Stamped titanium often exhibits slight surface roughness and subtle deformities from the high-pressure forming method, resulting in less refined visual quality. For applications demanding high-end appearance and tactile smoothness, machined titanium is typically preferred over stamped variants.

Environmental Impact of Machining vs Stamping

Machined titanium generates higher environmental impact due to increased energy consumption and material waste compared to stamped titanium, which uses less material and produces fewer emissions through its more efficient forming process. Machining titanium requires precision cutting and extensive use of coolants, leading to significant resource use and waste disposal challenges. Stamping titanium benefits from faster production rates and reduced energy inputs, making it a more sustainable option for large-scale manufacturing with lower carbon footprints.

Choosing the Right Method for Your Titanium Product

Machined titanium offers superior precision and surface finish, making it ideal for complex designs and high-performance applications where tolerance and strength are critical. Stamped titanium excels in high-volume production, providing cost-effective manufacturing with consistent quality for simpler shapes and thinner gauges. Selecting the right method depends on project requirements such as design complexity, production volume, mechanical properties, and budget constraints.

Machined Titanium vs Stamped Titanium Infographic

materialdif.com

materialdif.com