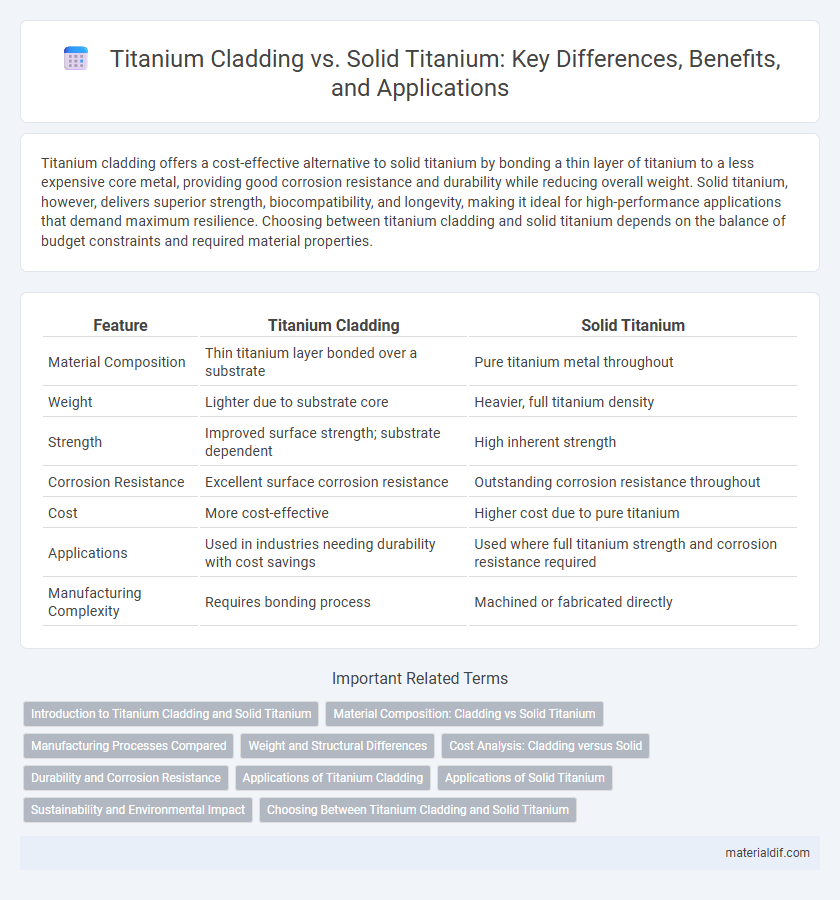

Titanium cladding offers a cost-effective alternative to solid titanium by bonding a thin layer of titanium to a less expensive core metal, providing good corrosion resistance and durability while reducing overall weight. Solid titanium, however, delivers superior strength, biocompatibility, and longevity, making it ideal for high-performance applications that demand maximum resilience. Choosing between titanium cladding and solid titanium depends on the balance of budget constraints and required material properties.

Table of Comparison

| Feature | Titanium Cladding | Solid Titanium |

|---|---|---|

| Material Composition | Thin titanium layer bonded over a substrate | Pure titanium metal throughout |

| Weight | Lighter due to substrate core | Heavier, full titanium density |

| Strength | Improved surface strength; substrate dependent | High inherent strength |

| Corrosion Resistance | Excellent surface corrosion resistance | Outstanding corrosion resistance throughout |

| Cost | More cost-effective | Higher cost due to pure titanium |

| Applications | Used in industries needing durability with cost savings | Used where full titanium strength and corrosion resistance required |

| Manufacturing Complexity | Requires bonding process | Machined or fabricated directly |

Introduction to Titanium Cladding and Solid Titanium

Titanium cladding involves bonding a thin layer of titanium onto a base metal to combine titanium's corrosion resistance with the strength and cost-effectiveness of the underlying material. Solid titanium refers to a homogeneous piece of pure titanium that offers exceptional strength, lightweight properties, and superior resistance to corrosion and high temperatures. While solid titanium provides unmatched durability, titanium cladding offers a practical balance between performance and affordability in various industrial applications.

Material Composition: Cladding vs Solid Titanium

Titanium cladding consists of a thin layer of pure titanium bonded to a base metal such as steel or aluminum, combining the corrosion resistance of titanium with the strength and cost-effectiveness of the substrate. Solid titanium is composed entirely of titanium or titanium alloys, offering superior durability, corrosion resistance, and high strength-to-weight ratio throughout the material. The material composition differences significantly impact performance, cost, and application suitability in aerospace, marine, and chemical industries.

Manufacturing Processes Compared

Titanium cladding involves bonding a thin layer of titanium onto a different metal substrate, typically through explosive bonding or roll bonding, offering cost efficiency and corrosion resistance without the high price of solid titanium. Solid titanium manufacturing requires processes like forging, casting, and machining, which demand more energy and result in higher material costs but provide superior strength and uniform properties. Cladding reduces weight and fabrication time, while solid titanium is preferred for applications needing full material integrity and maximum durability.

Weight and Structural Differences

Titanium cladding consists of a thin layer of titanium bonded to a different metal core, significantly reducing weight compared to solid titanium while maintaining corrosion resistance. Solid titanium offers superior structural integrity and strength, making it ideal for applications requiring high durability and load-bearing capacity. Cladded titanium panels provide a lightweight alternative with cost efficiency but may lack the full mechanical strength of solid titanium components.

Cost Analysis: Cladding versus Solid

Titanium cladding offers a cost-effective alternative to solid titanium by using a thin layer of titanium bonded to less expensive metals, significantly reducing material expenses while maintaining corrosion resistance and strength. Solid titanium provides superior durability and uniform material properties but comes with higher costs due to its full-body composition and machining requirements. Evaluating project specifications and budget constraints is crucial to determining whether the economic benefits of cladding outweigh the performance advantages of solid titanium.

Durability and Corrosion Resistance

Titanium cladding offers exceptional corrosion resistance by combining the surface protection of titanium with the cost-effectiveness of a less expensive core metal, making it ideal for harsh environments. Solid titanium provides superior durability and strength throughout the entire material, ensuring long-lasting performance under extreme mechanical stress and aggressive conditions. Both options resist oxidation and chemical attacks, but solid titanium excels in applications requiring high structural integrity, while cladding optimizes corrosion protection with reduced material costs.

Applications of Titanium Cladding

Titanium cladding is widely used in aerospace and marine industries for corrosion resistance while reducing weight and material costs compared to solid titanium. Its applications include chemical processing equipment and architectural exteriors where enhanced durability and aesthetic appeal are critical. Titanium cladding offers a cost-effective solution for environments demanding high strength-to-weight ratio and corrosion resistance without the expense of solid titanium.

Applications of Solid Titanium

Solid titanium is widely used in aerospace, medical implants, and marine applications due to its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. Its ability to withstand extreme temperatures and mechanical stress makes it ideal for aircraft structural components and surgical instruments. Unlike titanium cladding, which primarily serves as a protective or decorative layer, solid titanium provides full material integrity and durability essential for critical engineering applications.

Sustainability and Environmental Impact

Titanium cladding offers enhanced sustainability by using a thin layer of titanium bonded to a less expensive core material, reducing the overall demand for pure titanium extraction and lowering environmental impact associated with mining. Solid titanium, while highly durable and corrosion-resistant, requires significantly more raw titanium, leading to increased energy consumption and greenhouse gas emissions throughout its production cycle. Cladding technology supports resource efficiency and waste reduction, making it an environmentally preferable choice in industries prioritizing sustainable material solutions.

Choosing Between Titanium Cladding and Solid Titanium

Choosing between titanium cladding and solid titanium depends on budget, application, and desired properties. Titanium cladding offers cost-effective corrosion resistance by bonding a thin titanium layer to a less expensive metal core, ideal for applications requiring strength without high material costs. Solid titanium provides superior durability, biocompatibility, and strength, preferred in aerospace, medical implants, and high-stress environments where performance outweighs expense.

Titanium Cladding vs Solid Titanium Infographic

materialdif.com

materialdif.com