Anodized titanium enhances corrosion resistance and offers a vibrant range of colors through an electrochemical process, making it ideal for pet collars and accessories that combine durability with style. Raw titanium provides superior strength and lightweight benefits but lacks the colorful finish and enhanced surface protection of anodized versions. Choosing between the two depends on whether aesthetic appeal or a natural metal look is the priority for your pet products.

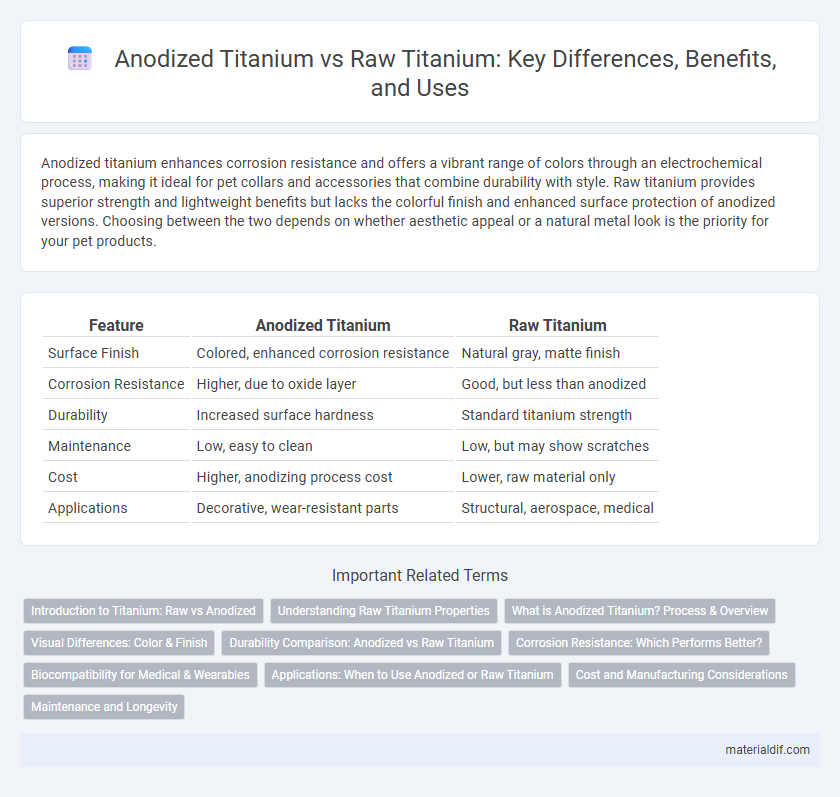

Table of Comparison

| Feature | Anodized Titanium | Raw Titanium |

|---|---|---|

| Surface Finish | Colored, enhanced corrosion resistance | Natural gray, matte finish |

| Corrosion Resistance | Higher, due to oxide layer | Good, but less than anodized |

| Durability | Increased surface hardness | Standard titanium strength |

| Maintenance | Low, easy to clean | Low, but may show scratches |

| Cost | Higher, anodizing process cost | Lower, raw material only |

| Applications | Decorative, wear-resistant parts | Structural, aerospace, medical |

Introduction to Titanium: Raw vs Anodized

Raw titanium offers superior strength, corrosion resistance, and biocompatibility, making it ideal for aerospace, medical, and industrial applications. Anodized titanium enhances surface hardness and provides vibrant, corrosion-resistant colors through an electrochemical process that thickens the oxide layer. This treatment improves wear resistance and aesthetic appeal without compromising the metal's inherent durability and lightweight properties.

Understanding Raw Titanium Properties

Raw titanium exhibits exceptional strength-to-weight ratio and corrosion resistance due to its naturally occurring oxide layer. Its unaltered surface maintains high biocompatibility and excellent fatigue resistance, making it ideal for medical implants and aerospace components. Unlike anodized titanium, raw titanium lacks enhanced surface color or texture but preserves its inherent durability and performance characteristics.

What is Anodized Titanium? Process & Overview

Anodized titanium undergoes an electrochemical process that increases its natural oxide layer, enhancing corrosion resistance and allowing for vibrant, customizable colors. This process involves submerging titanium in an electrolyte bath and applying an electric current, which thickens the oxide film without adding paint or dyes. Unlike raw titanium, anodized titanium offers improved durability and aesthetic variations ideal for applications in aerospace, medical devices, and jewelry.

Visual Differences: Color & Finish

Anodized titanium displays a vibrant range of colors, from deep blues to rich purples, due to the controlled oxidation process that alters the surface oxide layer thickness. Raw titanium typically exhibits a muted gray, matte finish with a natural metallic luster, lacking the iridescent hues of anodized variants. The anodized finish not only enhances aesthetic appeal but also provides a smooth, non-porous surface compared to the more textured appearance of raw titanium.

Durability Comparison: Anodized vs Raw Titanium

Anodized titanium exhibits enhanced corrosion resistance and surface hardness compared to raw titanium, significantly extending its durability in harsh environments. The anodizing process forms a stable oxide layer that protects the underlying metal from wear, oxidation, and chemical damage. Raw titanium, while inherently strong and corrosion-resistant, lacks this protective coating, making anodized titanium a superior choice for applications requiring long-term durability and resistance to surface degradation.

Corrosion Resistance: Which Performs Better?

Anodized titanium exhibits superior corrosion resistance compared to raw titanium due to its enhanced oxide layer, which acts as a protective barrier against environmental factors such as moisture, acids, and salts. The anodizing process thickens this titanium dioxide layer, significantly reducing the metal's vulnerability to oxidation and corrosion in harsh conditions. Raw titanium, while naturally corrosion-resistant, lacks the reinforced surface protection that anodizing provides, making anodized titanium the preferred choice for applications requiring extended durability and resistance to chemical degradation.

Biocompatibility for Medical & Wearables

Anodized titanium enhances biocompatibility by forming a durable oxide layer that improves corrosion resistance and minimizes ion release, critical for medical implants and wearable devices. In contrast, raw titanium, while inherently biocompatible due to its stable oxide surface, may be more susceptible to surface wear and degradation in biological environments. The anodization process also promotes better cell adhesion and reduces inflammatory responses, making anodized titanium a preferred choice for long-term biomedical applications.

Applications: When to Use Anodized or Raw Titanium

Anodized titanium offers enhanced corrosion resistance and vibrant color options, making it ideal for biomedical implants, aerospace components, and decorative applications where durability and aesthetics are crucial. Raw titanium provides superior strength-to-weight ratio and biocompatibility, suited for high-stress environments such as orthopedic implants, marine hardware, and industrial machinery. Choosing between anodized and raw titanium depends on specific application requirements, balancing surface protection and mechanical performance.

Cost and Manufacturing Considerations

Anodized titanium involves an electrochemical process that creates a protective oxide layer, which increases corrosion resistance and enhances surface hardness, but this treatment adds to manufacturing costs compared to raw titanium. Raw titanium, while less expensive due to minimal post-processing, may require more frequent maintenance or replacement in corrosive environments. Manufacturing considerations for anodized titanium include the need for precise control of voltage and time parameters to achieve desired oxide colors and thickness, impacting production time and expenses.

Maintenance and Longevity

Anodized titanium offers enhanced corrosion resistance and surface hardness compared to raw titanium, reducing the need for frequent maintenance and extending the material's lifespan in harsh environments. The anodization process creates a protective oxide layer that minimizes wear and prevents oxidation, ensuring sustained durability over time. Raw titanium, while naturally resistant to corrosion, is more prone to surface scratches and discoloration, requiring more regular upkeep to maintain its appearance and structural integrity.

Anodized Titanium vs Raw Titanium Infographic

materialdif.com

materialdif.com