Titanium forging involves shaping metal using compressive forces, resulting in a denser and stronger structure ideal for high-stress pet accessories like collars and tags. Titanium extrusion pushes heated metal through a die to create consistent shapes with excellent surface finish, suitable for lightweight and intricate pet products such as clips and charms. Both processes enhance titanium's durability and corrosion resistance, but forging offers superior mechanical properties for more demanding applications.

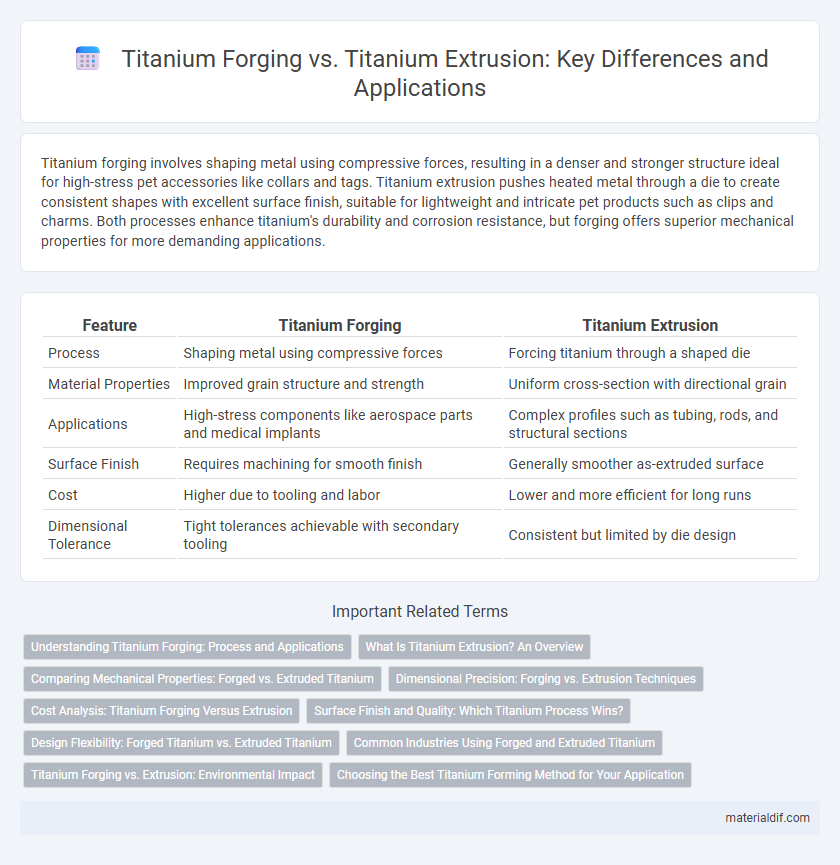

Table of Comparison

| Feature | Titanium Forging | Titanium Extrusion |

|---|---|---|

| Process | Shaping metal using compressive forces | Forcing titanium through a shaped die |

| Material Properties | Improved grain structure and strength | Uniform cross-section with directional grain |

| Applications | High-stress components like aerospace parts and medical implants | Complex profiles such as tubing, rods, and structural sections |

| Surface Finish | Requires machining for smooth finish | Generally smoother as-extruded surface |

| Cost | Higher due to tooling and labor | Lower and more efficient for long runs |

| Dimensional Tolerance | Tight tolerances achievable with secondary tooling | Consistent but limited by die design |

Understanding Titanium Forging: Process and Applications

Titanium forging involves shaping metal through localized compressive forces, enhancing its grain structure and mechanical properties for superior strength and durability. This process is widely applied in aerospace and medical industries where precise dimensions and high-performance materials are critical. Titanium forging produces components with improved fatigue resistance and structural integrity compared to titanium extrusion, making it ideal for demanding engineering applications.

What Is Titanium Extrusion? An Overview

Titanium extrusion is a manufacturing process where titanium billets are heated and forced through a shaped die to create long, continuous profiles with uniform cross-sections. This method produces complex shapes with excellent mechanical properties, high strength-to-weight ratios, and superior corrosion resistance ideal for aerospace and medical applications. Compared to forging, extrusion offers greater dimensional accuracy and surface finish, making it suitable for intricate designs and large-scale production.

Comparing Mechanical Properties: Forged vs. Extruded Titanium

Forged titanium exhibits superior mechanical strength, enhanced fatigue resistance, and improved grain structure compared to extruded titanium, making it ideal for high-stress aerospace and automotive applications. Extruded titanium provides better dimensional accuracy and consistent cross-sectional profiles but generally has lower tensile strength and ductility. The choice between forging and extrusion depends on balancing mechanical performance requirements with manufacturing precision and cost efficiency.

Dimensional Precision: Forging vs. Extrusion Techniques

Titanium forging offers superior dimensional precision due to the controlled deformation process, which results in a fine-grained microstructure and enhanced mechanical properties. In contrast, titanium extrusion provides less accurate dimensions because the metal is forced through a die, often leading to variations in cross-sectional consistency. Forging also minimizes internal defects, ensuring tighter tolerances critical for aerospace and medical applications requiring exact specifications.

Cost Analysis: Titanium Forging Versus Extrusion

Titanium forging generally incurs higher initial costs due to the complex dies and machining processes required, but it offers superior mechanical properties and material utilization, potentially reducing long-term expenses in high-performance applications. Extrusion of titanium involves lower upfront tooling costs and faster production rates, making it economically favorable for simpler, high-volume parts with less critical structural demands. Evaluating cost-effectiveness depends on factors like production volume, part complexity, and required mechanical performance, where forging is optimal for strength-intensive components and extrusion excels in cost-sensitive, less demanding uses.

Surface Finish and Quality: Which Titanium Process Wins?

Titanium forging typically produces a superior surface finish compared to titanium extrusion due to its ability to minimize surface irregularities and achieve finer grain structures. Forging enhances mechanical properties and uniformity, resulting in higher quality, more durable components with fewer defects. While extrusion allows for complex shapes, forging consistently delivers better surface integrity and overall material performance.

Design Flexibility: Forged Titanium vs. Extruded Titanium

Forged titanium offers superior design flexibility due to its ability to produce complex, high-strength components with fine grain structure and enhanced mechanical properties. Extruded titanium is ideal for simpler, uniform cross-sections but lacks the intricate detailing achievable through forging processes. Choosing forged titanium enables engineers to optimize parts for critical performance applications requiring tailored geometries and durability.

Common Industries Using Forged and Extruded Titanium

Aerospace, automotive, and medical industries prominently utilize forged titanium for its superior strength and fatigue resistance in critical components like engine parts and surgical implants. Extruded titanium finds widespread use in chemical processing, military, and marine applications due to its excellent corrosion resistance and ability to form complex cross-sectional shapes. Both processes serve essential roles in manufacturing durable, lightweight parts tailored to demanding industry specifications.

Titanium Forging vs. Extrusion: Environmental Impact

Titanium forging typically results in lower greenhouse gas emissions compared to extrusion due to its more energy-efficient process and reduced material waste. Extrusion of titanium requires higher temperatures and longer processing times, increasing overall energy consumption and corresponding carbon footprint. Choosing forging over extrusion contributes to a smaller environmental impact by optimizing resource use and minimizing industrial emissions in titanium manufacturing.

Choosing the Best Titanium Forming Method for Your Application

Titanium forging offers superior strength and grain refinement, making it ideal for high-stress aerospace and medical components, while titanium extrusion provides excellent dimensional accuracy and is suitable for complex cross-sectional shapes. Choosing the best titanium forming method depends on factors such as application load requirements, part complexity, and production volume. Prioritizing forging enhances mechanical performance in critical applications, whereas extrusion optimizes design flexibility and cost-efficiency for intricate profiles.

Titanium Forging vs Titanium Extrusion Infographic

materialdif.com

materialdif.com