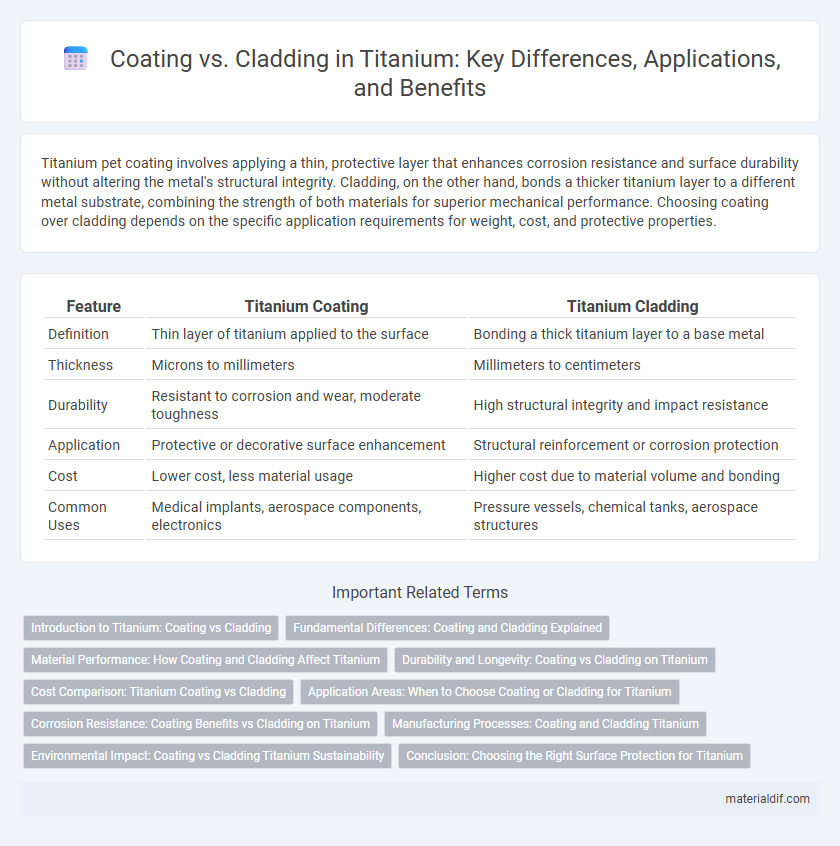

Titanium pet coating involves applying a thin, protective layer that enhances corrosion resistance and surface durability without altering the metal's structural integrity. Cladding, on the other hand, bonds a thicker titanium layer to a different metal substrate, combining the strength of both materials for superior mechanical performance. Choosing coating over cladding depends on the specific application requirements for weight, cost, and protective properties.

Table of Comparison

| Feature | Titanium Coating | Titanium Cladding |

|---|---|---|

| Definition | Thin layer of titanium applied to the surface | Bonding a thick titanium layer to a base metal |

| Thickness | Microns to millimeters | Millimeters to centimeters |

| Durability | Resistant to corrosion and wear, moderate toughness | High structural integrity and impact resistance |

| Application | Protective or decorative surface enhancement | Structural reinforcement or corrosion protection |

| Cost | Lower cost, less material usage | Higher cost due to material volume and bonding |

| Common Uses | Medical implants, aerospace components, electronics | Pressure vessels, chemical tanks, aerospace structures |

Introduction to Titanium: Coating vs Cladding

Titanium coating involves applying a thin protective or decorative layer onto the titanium surface, enhancing corrosion resistance, wear resistance, and aesthetic appeal. Cladding refers to bonding titanium sheets to another metal substrate, combining the strength or cost-effectiveness of the base metal with titanium's corrosion resistance and lightweight properties. Both techniques serve to optimize titanium's performance in demanding industries such as aerospace, medical devices, and chemical processing.

Fundamental Differences: Coating and Cladding Explained

Coating involves applying a thin layer of titanium or another material to a substrate surface to enhance properties such as corrosion resistance and aesthetics, typically measured in microns. Cladding, in contrast, refers to bonding a thicker titanium layer onto a base metal, often by metallurgical processes like explosive bonding or rolling, providing structural strength and corrosion protection. The fundamental difference lies in thickness and application method, with coatings being surface treatments and cladding offering a metallurgically bonded metal layer.

Material Performance: How Coating and Cladding Affect Titanium

Coating enhances titanium's surface properties by providing corrosion resistance and improved wear durability without altering the base metal's mechanical strength. Cladding involves bonding a titanium layer to another metal, significantly increasing structural integrity and resistance to harsh environments but potentially changing mechanical behavior due to differing material properties. Both processes optimize titanium's performance in aerospace, medical, and industrial applications by addressing specific operational demands through surface engineering.

Durability and Longevity: Coating vs Cladding on Titanium

Titanium cladding offers superior durability and longevity compared to coatings due to its robust metallurgical bond and resistance to peeling or cracking under extreme conditions. Coatings on titanium, while providing corrosion and wear protection, tend to degrade faster over time, especially under high abrasion or thermal cycling. Cladding ensures extended service life in aerospace, marine, and chemical processing applications by maintaining structural integrity and corrosion resistance.

Cost Comparison: Titanium Coating vs Cladding

Titanium coating generally offers a lower upfront cost compared to cladding due to thinner material usage and less intensive processing requirements. Cladding involves bonding thicker titanium layers to a substrate, resulting in higher material and labor expenses but enhanced durability for heavy-duty applications. Cost efficiency between titanium coating and cladding depends on factors like application environment, required thickness, and expected service life.

Application Areas: When to Choose Coating or Cladding for Titanium

Coating titanium is ideal for applications requiring enhanced surface properties such as increased corrosion resistance, wear resistance, or improved biocompatibility, commonly seen in aerospace, medical implants, and chemical processing equipment. Cladding titanium is preferred when structural strength, impact resistance, and corrosion protection must be combined, often utilized in shipbuilding, power plants, and industrial pressure vessels. Selecting coating or cladding depends on specific environmental conditions, mechanical demands, and cost-effectiveness for the industrial application.

Corrosion Resistance: Coating Benefits vs Cladding on Titanium

Coating titanium enhances corrosion resistance by providing a uniform, protective barrier that prevents direct exposure to aggressive environments, effectively reducing surface degradation. Cladding, while offering mechanical strength and impact resistance, may introduce potential galvanic corrosion at interface boundaries if dissimilar metals are used. Optimal corrosion resistance performance depends on coating adhesion quality and the selection of compatible, corrosion-resistant coating materials such as titanium nitride or ceramic-based compounds.

Manufacturing Processes: Coating and Cladding Titanium

Coating titanium involves applying a thin, protective layer through processes such as physical vapor deposition (PVD) or chemical vapor deposition (CVD), enhancing corrosion resistance and surface hardness without altering the base metal. Cladding titanium entails bonding a titanium layer onto a different metal substrate using techniques like explosive welding or rolling, creating composite materials that combine titanium's corrosion resistance with substrate strength. Manufacturing efficiency in coating favors precision and thin films, while cladding supports thicker, structural layers for aerospace and chemical processing applications.

Environmental Impact: Coating vs Cladding Titanium Sustainability

Coating titanium typically involves applying thin layers using processes such as PVD or anodizing, which consume less energy and generate fewer emissions compared to cladding techniques that require bonding additional metal layers. Cladding increases material usage and often involves high-temperature treatments, leading to higher carbon footprints and more waste. Sustainable titanium practices favor coatings for their lower environmental impact and resource efficiency.

Conclusion: Choosing the Right Surface Protection for Titanium

Coating titanium offers enhanced corrosion resistance and surface hardness without altering the base metal's mechanical properties, ideal for applications requiring precise dimensional tolerances. Cladding provides a metallurgically bonded outer layer that improves wear resistance and chemical stability, suitable for heavy-duty environments with high abrasion or chemical exposure. Selecting the right surface protection depends on the specific operational demands, balancing durability, cost, and performance requirements to optimize titanium's long-term functionality.

Coating vs Cladding Infographic

materialdif.com

materialdif.com