Bar stock titanium is generally more cost-effective and widely available, making it ideal for producing standard shapes and sizes in pet products. Billet titanium offers superior structural integrity and customization options, often used for high-performance or precision applications in titanium pet accessories. Both materials provide exceptional strength, corrosion resistance, and biocompatibility, critical factors in durable and safe titanium pet products.

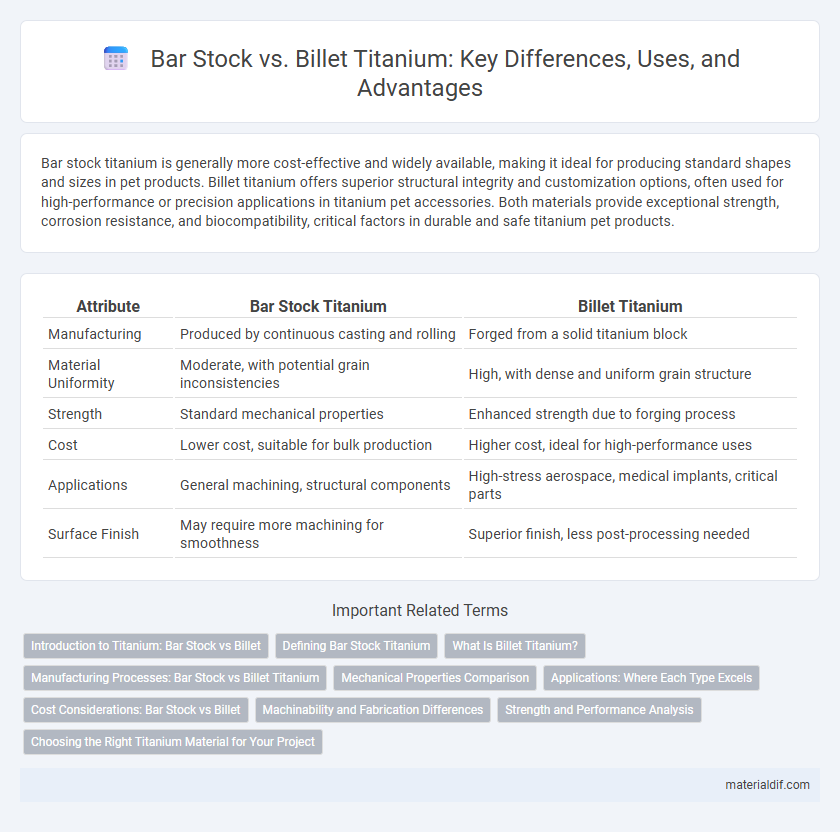

Table of Comparison

| Attribute | Bar Stock Titanium | Billet Titanium |

|---|---|---|

| Manufacturing | Produced by continuous casting and rolling | Forged from a solid titanium block |

| Material Uniformity | Moderate, with potential grain inconsistencies | High, with dense and uniform grain structure |

| Strength | Standard mechanical properties | Enhanced strength due to forging process |

| Cost | Lower cost, suitable for bulk production | Higher cost, ideal for high-performance uses |

| Applications | General machining, structural components | High-stress aerospace, medical implants, critical parts |

| Surface Finish | May require more machining for smoothness | Superior finish, less post-processing needed |

Introduction to Titanium: Bar Stock vs Billet

Titanium bar stock is typically produced through continuous casting and rolling, resulting in standardized shapes and sizes ideal for mass production and machining efficiency. In contrast, titanium billet is a solid piece of metal forged or cast into a near-net shape, offering superior structural integrity and uniform grain flow crucial for high-performance aerospace and medical applications. Understanding the differences in manufacturing, mechanical properties, and surface finish between titanium bar stock and billet is essential for selecting the right material for specific engineering and fabrication needs.

Defining Bar Stock Titanium

Bar stock titanium refers to raw metal formed into long, standardized shapes such as rods, bars, or strips, commonly produced through extrusion or rolling processes. It offers uniform mechanical properties and is typically used in machining applications where precise dimensions and consistency are critical. Bar stock titanium provides an efficient and cost-effective starting material for manufacturing components in aerospace, medical, and automotive industries.

What Is Billet Titanium?

Billet titanium is a solid piece of titanium metal created through forging or casting processes, providing superior strength and uniformity compared to bar stock. Unlike bar stock, which is typically rolled or extruded, billet titanium offers enhanced mechanical properties due to its refined grain structure and reduced impurities. This makes billet titanium ideal for high-performance applications requiring exceptional durability and precision.

Manufacturing Processes: Bar Stock vs Billet Titanium

Bar stock titanium is produced through continuous casting followed by hot rolling or forging, resulting in long, uniform shapes ideal for machining into standard-sized components. Billet titanium undergoes precision forging or extrusion from a solid cylindrical ingot, offering superior grain structure and mechanical properties for critical aerospace and medical applications. The manufacturing process of billet titanium allows tighter tolerances and enhanced strength compared to bar stock, making it suitable for complex, high-performance parts.

Mechanical Properties Comparison

Bar stock titanium offers uniform mechanical properties with consistent tensile strength typically ranging from 900 to 1200 MPa, making it suitable for precision applications. Billet titanium, formed through solid forging, exhibits superior strength and toughness due to its refined microstructure, often achieving tensile strengths above 1200 MPa. The choice between bar stock and billet titanium depends on performance requirements, with billet providing enhanced fatigue resistance and ductility for critical aerospace and medical implants.

Applications: Where Each Type Excels

Bar stock titanium is ideal for applications requiring precision machining and consistent diameters, such as aerospace fasteners and medical implants. Billet titanium excels in complex, high-strength components like aerospace structural parts and high-performance automotive components due to its homogeneity and superior mechanical properties. Choosing between bar stock and billet depends on the complexity, size, and strength requirements of the final titanium product.

Cost Considerations: Bar Stock vs Billet

Bar stock titanium generally costs less than billet due to its standardized shapes and sizes, which reduce machining and production expenses. Billet titanium, often custom-cast or forged, incurs higher costs linked to its tailored dimensions and superior mechanical properties for specialized applications. Choosing between bar stock and billet depends on balancing budget constraints with performance requirements in aerospace, medical, and industrial uses.

Machinability and Fabrication Differences

Titanium bar stock offers improved machinability compared to billet titanium due to its uniform grain structure and consistent mechanical properties, resulting in smoother cutting and less tool wear. Billet titanium, produced through forged or cast processes, exhibits a denser microstructure that can lead to increased fabrication difficulty and longer machining times. Understanding these material differences is crucial for optimizing manufacturing efficiency and achieving precise dimensional tolerances in aerospace and medical applications.

Strength and Performance Analysis

Titanium billet exhibits superior strength and performance compared to bar stock due to its near-net shape manufacturing, which minimizes grain size and internal defects. The refined microstructure of billet titanium enhances tensile strength, fatigue resistance, and overall durability, making it ideal for high-performance aerospace and medical applications. Bar stock, while cost-effective and suitable for simpler geometries, often has coarser grain and residual stresses that can limit its mechanical properties under demanding conditions.

Choosing the Right Titanium Material for Your Project

Bar stock titanium offers consistent dimensions and is ideal for mass production with tight tolerances, while billet titanium provides superior structural integrity and customization for complex or high-stress applications. Selecting the right titanium material depends on project requirements such as mechanical properties, size constraints, and finishing processes. Consider billets for aerospace or medical implants needing exceptional strength, whereas bar stock suits automotive parts and general manufacturing where uniformity and cost-efficiency are priorities.

Bar Stock vs Billet Titanium Infographic

materialdif.com

materialdif.com