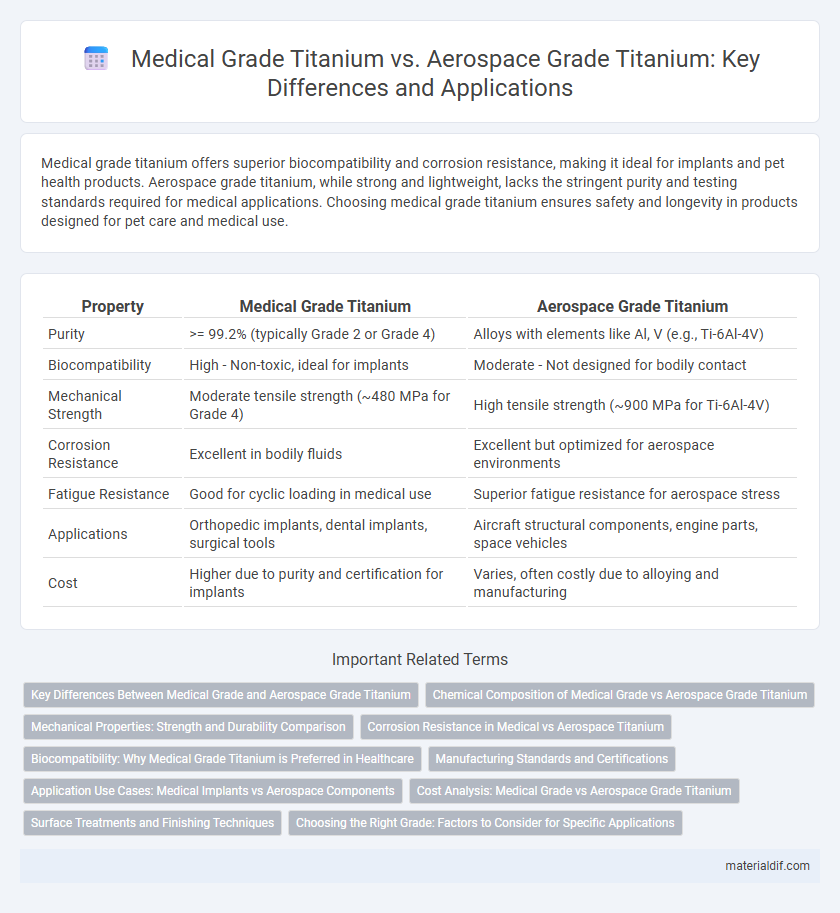

Medical grade titanium offers superior biocompatibility and corrosion resistance, making it ideal for implants and pet health products. Aerospace grade titanium, while strong and lightweight, lacks the stringent purity and testing standards required for medical applications. Choosing medical grade titanium ensures safety and longevity in products designed for pet care and medical use.

Table of Comparison

| Property | Medical Grade Titanium | Aerospace Grade Titanium |

|---|---|---|

| Purity | >= 99.2% (typically Grade 2 or Grade 4) | Alloys with elements like Al, V (e.g., Ti-6Al-4V) |

| Biocompatibility | High - Non-toxic, ideal for implants | Moderate - Not designed for bodily contact |

| Mechanical Strength | Moderate tensile strength (~480 MPa for Grade 4) | High tensile strength (~900 MPa for Ti-6Al-4V) |

| Corrosion Resistance | Excellent in bodily fluids | Excellent but optimized for aerospace environments |

| Fatigue Resistance | Good for cyclic loading in medical use | Superior fatigue resistance for aerospace stress |

| Applications | Orthopedic implants, dental implants, surgical tools | Aircraft structural components, engine parts, space vehicles |

| Cost | Higher due to purity and certification for implants | Varies, often costly due to alloying and manufacturing |

Key Differences Between Medical Grade and Aerospace Grade Titanium

Medical grade titanium, primarily composed of ASTM F136 or F67 alloys, offers superior biocompatibility and corrosion resistance essential for implants and prosthetics. Aerospace grade titanium, often based on alloys such as Ti-6Al-4V, emphasizes high strength-to-weight ratio and fatigue resistance critical for aircraft structural components. The key differences lie in their chemical composition, mechanical properties, and surface treatments tailored to meet stringent medical safety standards versus aerospace performance requirements.

Chemical Composition of Medical Grade vs Aerospace Grade Titanium

Medical grade titanium primarily consists of ASTM F136 and ASTM F67 standards, emphasizing high purity with minimal alloying elements such as aluminum, vanadium, and iron to maximize biocompatibility and corrosion resistance. Aerospace grade titanium, commonly represented by Ti-6Al-4V (Grade 5), contains approximately 6% aluminum and 4% vanadium, providing superior strength-to-weight ratio and fatigue resistance essential for structural applications. The chemical composition variance directly impacts mechanical properties and suitability, with medical grade titanium prioritizing bio-inertness while aerospace grade titanium balances strength and durability for high-stress environments.

Mechanical Properties: Strength and Durability Comparison

Medical grade titanium, primarily composed of Ti-6Al-4V alloy, offers excellent biocompatibility with a tensile strength of approximately 900 MPa, ensuring durability ideal for implants and prosthetics. Aerospace grade titanium, often utilizing Ti-6Al-4V ELI and other high-strength alloys, exceeds 1000 MPa in tensile strength, providing superior fatigue resistance and corrosion durability for demanding aviation environments. The mechanical properties of aerospace grade titanium highlight enhanced strength and durability, while medical grade titanium balances sufficient strength with optimal biological compatibility.

Corrosion Resistance in Medical vs Aerospace Titanium

Medical grade titanium, primarily composed of Ti-6Al-4V ELI alloy, exhibits superior corrosion resistance in body fluids due to its biocompatible oxide layer, making it ideal for implants and surgical instruments. Aerospace grade titanium, while also corrosion-resistant, is often alloyed for enhanced strength and fatigue resistance, which can compromise corrosion performance in aggressive environments compared to medical grade variants. Both grades utilize titanium's naturally forming oxide film, but the medical grade is specifically optimized to withstand the complex chemical environment of the human body.

Biocompatibility: Why Medical Grade Titanium is Preferred in Healthcare

Medical grade titanium demonstrates superior biocompatibility due to its high corrosion resistance and non-toxic properties, making it ideal for implants and surgical instruments. Unlike aerospace grade titanium, which prioritizes strength-to-weight ratio and fatigue resistance for flight applications, medical grade titanium is specifically alloyed and processed to prevent adverse bodily reactions. This ensures patient safety and long-term implant success in healthcare settings.

Manufacturing Standards and Certifications

Medical grade titanium, primarily ASTM F67 and F136, meets stringent biocompatibility and corrosion resistance standards essential for implants and surgical instruments. Aerospace grade titanium adheres to strict certifications such as AMS 4928 and AMS 4911, emphasizing high strength-to-weight ratios and fatigue resistance in extreme environments. Manufacturing processes for medical titanium involve precise surface treatments and ultra-clean environments, while aerospace titanium production focuses on toughness and dimensional stability under thermal stress.

Application Use Cases: Medical Implants vs Aerospace Components

Medical grade titanium, known for its high biocompatibility and corrosion resistance, is primarily used in implants such as joint replacements, dental implants, and surgical instruments to ensure long-term durability and patient safety. Aerospace grade titanium features superior strength-to-weight ratios and enhanced fatigue resistance, making it ideal for aircraft structural components, engine parts, and airframes where performance under extreme conditions is critical. The distinct alloy compositions and mechanical properties of medical versus aerospace titanium grades optimize their function-specific applications in healthcare and aerospace industries.

Cost Analysis: Medical Grade vs Aerospace Grade Titanium

Medical grade titanium, primarily alloyed as Ti-6Al-4V ELI, commands higher costs due to rigorous biocompatibility testing and certification standards essential for implants and prosthetics. Aerospace grade titanium, often Ti-6Al-4V, benefits from large-scale manufacturing and less stringent purity requirements, resulting in lower production expenses. The cost difference reflects the added value of medical-grade titanium's enhanced corrosion resistance, traceability, and sterilization compatibility crucial for healthcare applications.

Surface Treatments and Finishing Techniques

Medical grade titanium undergoes precise surface treatments such as anodizing, acid etching, and passivation to enhance biocompatibility, corrosion resistance, and osseointegration crucial for implants. Aerospace grade titanium features advanced finishing techniques like shot peening, plasma spraying, and chemical milling to improve fatigue resistance, thermal stability, and surface smoothness required for high-stress environments. Both grades use specialized polishing and coating methods tailored to their distinct performance standards and operational demands.

Choosing the Right Grade: Factors to Consider for Specific Applications

Medical grade titanium, primarily ASTM F67 and F136 alloys, offers exceptional biocompatibility and corrosion resistance, essential for implants and surgical instruments. Aerospace grade titanium, such as Ti-6Al-4V, emphasizes high strength-to-weight ratio, fatigue resistance, and performance under extreme conditions, critical for structural aircraft components. Selecting the right grade depends on application-specific factors like mechanical properties, corrosion requirements, biocompatibility, and regulatory standards.

Medical Grade Titanium vs Aerospace Grade Titanium Infographic

materialdif.com

materialdif.com