Biomedical titanium is specially processed to meet strict biocompatibility standards, ensuring it is safe for implants and medical devices by minimizing allergic reactions and corrosion. Aerospace titanium, on the other hand, is engineered for high strength-to-weight ratios and resistance to extreme temperatures, making it suitable for aircraft structures and engines. Both types offer superior durability, but their chemical purity and surface treatments differ significantly to cater to their unique applications.

Table of Comparison

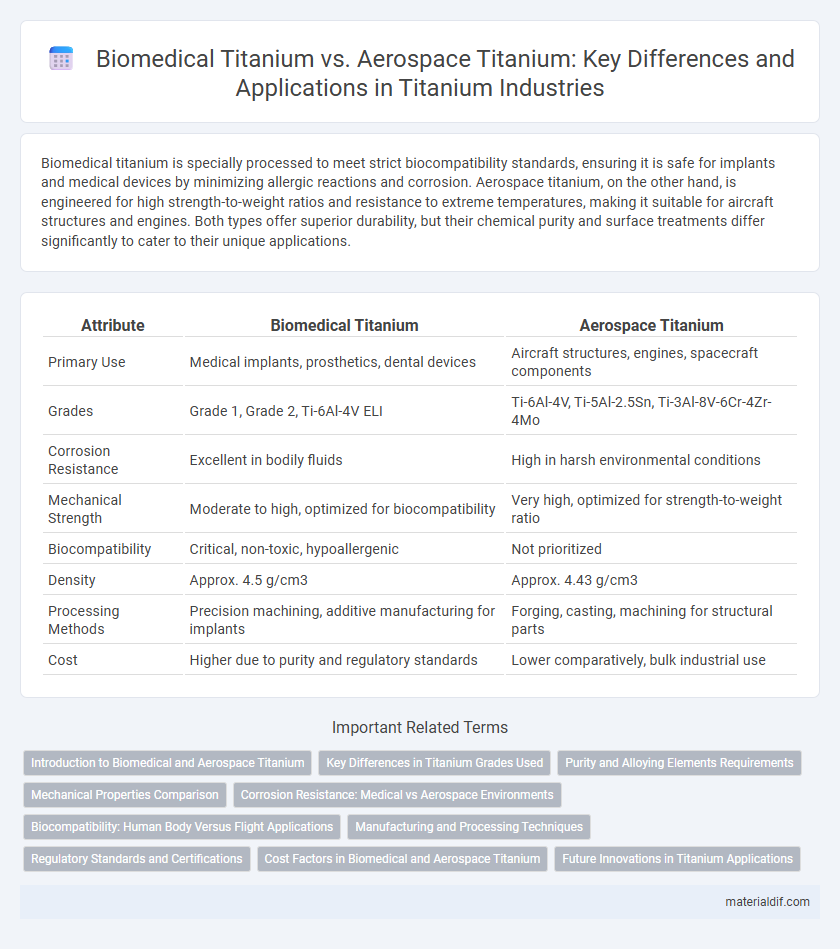

| Attribute | Biomedical Titanium | Aerospace Titanium |

|---|---|---|

| Primary Use | Medical implants, prosthetics, dental devices | Aircraft structures, engines, spacecraft components |

| Grades | Grade 1, Grade 2, Ti-6Al-4V ELI | Ti-6Al-4V, Ti-5Al-2.5Sn, Ti-3Al-8V-6Cr-4Zr-4Mo |

| Corrosion Resistance | Excellent in bodily fluids | High in harsh environmental conditions |

| Mechanical Strength | Moderate to high, optimized for biocompatibility | Very high, optimized for strength-to-weight ratio |

| Biocompatibility | Critical, non-toxic, hypoallergenic | Not prioritized |

| Density | Approx. 4.5 g/cm3 | Approx. 4.43 g/cm3 |

| Processing Methods | Precision machining, additive manufacturing for implants | Forging, casting, machining for structural parts |

| Cost | Higher due to purity and regulatory standards | Lower comparatively, bulk industrial use |

Introduction to Biomedical and Aerospace Titanium

Biomedical titanium is specifically engineered for medical implants and devices due to its exceptional biocompatibility, corrosion resistance, and strength-to-weight ratio, ensuring safety and durability inside the human body. Aerospace titanium, on the other hand, is designed for high-performance applications requiring superior strength, heat resistance, and lightweight properties to withstand extreme environmental conditions in aircraft and spacecraft. Both grades rely on titanium's unique properties but differ in alloy compositions and processing methods tailored to their specialized uses.

Key Differences in Titanium Grades Used

Biomedical titanium primarily utilizes Grade 2 and Grade 5 alloys, favoring biocompatibility and corrosion resistance essential for implants and prosthetics. Aerospace titanium grades often include Grade 5 (Ti-6Al-4V) and Grade 9 (Ti-3Al-2.5V) alloys, selected for their high strength-to-weight ratios and fatigue resistance critical in aircraft structures. The key differences lie in the alloy composition and mechanical properties tailored to meet stringent medical safety standards versus aerospace performance demands.

Purity and Alloying Elements Requirements

Biomedical titanium demands ultra-high purity levels with minimal alloying elements to ensure biocompatibility and prevent adverse tissue reactions, typically containing over 99.5% titanium with trace amounts of oxygen, nitrogen, and iron. Aerospace titanium alloys prioritize a balance of strength, corrosion resistance, and weight, often incorporating aluminum, vanadium, and molybdenum to enhance mechanical properties for high-stress environments. The purity standards for aerospace titanium are less stringent than biomedical grade, allowing for higher concentrations of alloying elements that optimize performance but may reduce biocompatibility.

Mechanical Properties Comparison

Biomedical titanium alloys, such as Ti-6Al-4V ELI, exhibit superior biocompatibility and corrosion resistance while maintaining high tensile strength around 900 MPa, ideal for implants requiring durability and biological safety. Aerospace titanium alloys prioritize strength-to-weight ratios with tensile strengths exceeding 1000 MPa and enhanced fatigue resistance to withstand cyclic stresses in aircraft structures. Mechanical properties like yield strength, elongation, and fracture toughness are tailored differently, with biomedical grades emphasizing ductility and corrosion resistance and aerospace grades focusing on maximum strength and fatigue life.

Corrosion Resistance: Medical vs Aerospace Environments

Biomedical titanium exhibits superior corrosion resistance in physiological environments due to its stable oxide layer that endures bodily fluids and sterilization processes. Aerospace titanium is engineered to withstand corrosive agents like salt spray, high humidity, and temperature fluctuations encountered in flight conditions. The distinct alloy compositions and surface treatments optimize corrosion resistance tailored to medical implants versus aerospace structural components.

Biocompatibility: Human Body Versus Flight Applications

Biomedical titanium exhibits exceptional biocompatibility, allowing for seamless integration with human tissues, minimized allergic reactions, and resistance to bodily fluids, making it ideal for implants and prosthetics. Aerospace titanium prioritizes strength-to-weight ratio and corrosion resistance under extreme temperature and stress conditions, with biocompatibility considerations being secondary to flight performance. Despite differences, both biomedical and aerospace grades maintain titanium's core properties, such as corrosion resistance and durability, tailored to their specific environmental requirements.

Manufacturing and Processing Techniques

Biomedical titanium typically undergoes precision machining, electrochemical polishing, and passivation to achieve biocompatible surfaces, ensuring corrosion resistance and osseointegration for implants. Aerospace titanium is processed using advanced forging, heat treatment, and machining techniques to maximize strength-to-weight ratio and fatigue resistance under extreme conditions. Additive manufacturing and powder metallurgy are increasingly employed in both sectors to enhance material properties and design complexity.

Regulatory Standards and Certifications

Biomedical titanium must comply with stringent regulatory standards such as ISO 13485 and FDA 21 CFR Part 820, ensuring biocompatibility and patient safety for implants and medical devices. Aerospace titanium adheres to certifications like AS9100 and AMS specifications, focusing on mechanical performance and reliability under extreme conditions. These distinct regulatory frameworks reflect the critical performance and safety requirements specific to medical and aerospace applications.

Cost Factors in Biomedical and Aerospace Titanium

Biomedical titanium alloys, such as Ti-6Al-4V ELI, incur higher costs due to rigorous biocompatibility testing, sterilization processes, and adherence to stringent medical-grade standards. Aerospace-grade titanium, while also expensive, involves costs driven by high-performance specifications, fatigue resistance, and precision manufacturing for extreme environmental conditions. The disparity in cost factors between biomedical and aerospace titanium primarily stems from differing regulatory requirements and application-specific material certifications.

Future Innovations in Titanium Applications

Biomedical titanium alloys prioritize biocompatibility and corrosion resistance, enabling advancements in implant design and tissue engineering for enhanced patient outcomes. Aerospace titanium grades emphasize high strength-to-weight ratios and fatigue resistance, driving innovations in fuel efficiency and structural performance in next-generation aircraft. Future developments will likely focus on hybrid alloys and additive manufacturing techniques to merge these properties, expanding titanium's role across both biomedical and aerospace industries.

Biomedical Titanium vs Aerospace Titanium Infographic

materialdif.com

materialdif.com