A Titanium Bar offers superior strength and rigidity compared to Titanium Wire, making it ideal for structural applications requiring high durability and resistance to bending. Titanium Wire provides exceptional flexibility and is commonly used in applications needing lightweight, corrosion-resistant, and easily shaped materials. Choosing between the two depends on the balance of strength versus flexibility required for the specific pet or medical device application.

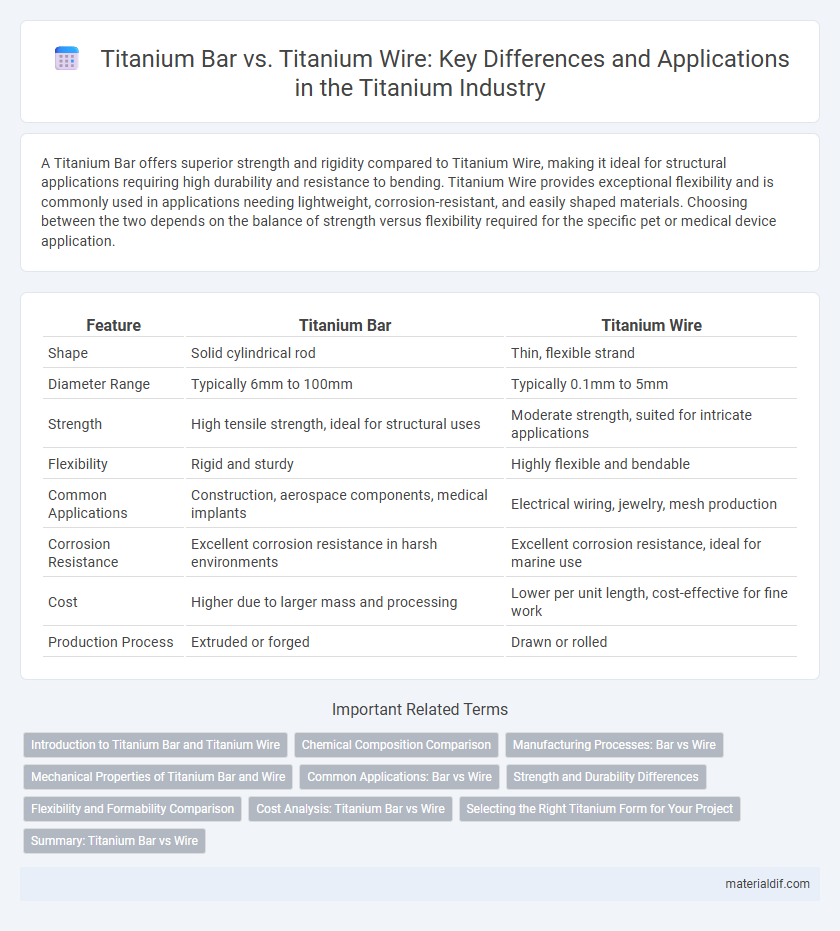

Table of Comparison

| Feature | Titanium Bar | Titanium Wire |

|---|---|---|

| Shape | Solid cylindrical rod | Thin, flexible strand |

| Diameter Range | Typically 6mm to 100mm | Typically 0.1mm to 5mm |

| Strength | High tensile strength, ideal for structural uses | Moderate strength, suited for intricate applications |

| Flexibility | Rigid and sturdy | Highly flexible and bendable |

| Common Applications | Construction, aerospace components, medical implants | Electrical wiring, jewelry, mesh production |

| Corrosion Resistance | Excellent corrosion resistance in harsh environments | Excellent corrosion resistance, ideal for marine use |

| Cost | Higher due to larger mass and processing | Lower per unit length, cost-effective for fine work |

| Production Process | Extruded or forged | Drawn or rolled |

Introduction to Titanium Bar and Titanium Wire

Titanium bars are solid, cylindrical metal rods commonly used in manufacturing for their strength, corrosion resistance, and lightweight properties, making them ideal for aerospace and medical applications. Titanium wires are thin, flexible strands utilized in electronics, jewelry, and surgical devices due to their high tensile strength and biocompatibility. Both forms offer exceptional durability and corrosion resistance, but their distinct shapes cater to different industrial needs.

Chemical Composition Comparison

Titanium bars and titanium wires primarily share a high-purity titanium composition, typically above 99.2% Ti, which ensures excellent corrosion resistance and strength. Variations in alloying elements such as aluminum, vanadium, or iron depend on the specific grade, with Grade 5 titanium (Ti-6Al-4V) commonly used for bars offering enhanced mechanical properties due to its 6% aluminum and 4% vanadium content. Titanium wires often utilize commercially pure titanium (Grades 1-4) with minimal alloying to maintain flexibility and conductivity, highlighting a distinction in chemical composition tailored to their respective industrial applications.

Manufacturing Processes: Bar vs Wire

Titanium bars are typically produced through a hot rolling or forging process that involves heating titanium ingots and shaping them into solid, cylindrical forms with precise dimensions and grain structures. In contrast, titanium wires undergo a series of cold drawing processes, where the material is pulled through progressively smaller dies to achieve the desired diameter and tensile strength while maintaining high ductility and surface finish. The manufacturing of bars emphasizes bulk shaping and mechanical strength, whereas wire production focuses on achieving fine dimensions and flexibility for specialized applications.

Mechanical Properties of Titanium Bar and Wire

Titanium bars exhibit superior tensile strength and rigidity compared to titanium wires, making them ideal for structural and load-bearing applications. Titanium wire offers greater flexibility and ductility, facilitating intricate shapes and fine detail work without compromising corrosion resistance. Both forms maintain excellent mechanical properties inherent to titanium, such as high strength-to-weight ratio and exceptional fatigue resistance.

Common Applications: Bar vs Wire

Titanium bars are commonly used in aerospace components, medical implants, and structural applications requiring high strength and machinability. Titanium wires find widespread use in dental appliances, fine mesh fabrics, and electronic connectors where flexibility and precision are essential. Both forms play critical roles in industries demanding corrosion resistance and biocompatibility, yet bars are preferred for heavy-duty fabrication while wires suit detailed or intricate designs.

Strength and Durability Differences

Titanium bars exhibit superior strength and durability compared to titanium wires due to their larger cross-sectional area and solid structure, making them ideal for heavy-duty applications. The density and uniformity of titanium bars offer enhanced resistance to bending and fatigue, whereas titanium wires, being thinner and more flexible, are better suited for applications requiring tensile strength and flexibility. Both materials maintain titanium's inherent corrosion resistance and biocompatibility, but bars provide greater mechanical stability under stress.

Flexibility and Formability Comparison

Titanium wire offers greater flexibility than titanium bar, allowing for intricate bending and forging into complex shapes with reduced risk of cracking. In contrast, titanium bar exhibits higher structural rigidity, making it ideal for applications that require strong, load-bearing components but limiting its ease of formability. The choice between titanium bar and wire depends on whether flexibility for detailed shaping or robust strength is prioritized in the specific engineering or manufacturing context.

Cost Analysis: Titanium Bar vs Wire

Titanium bars typically incur higher material and machining costs compared to titanium wire due to their larger cross-sectional area and the additional processing required for shaping. Wire production benefits from continuous drawing processes that reduce manufacturing expenses and waste, resulting in lower overall costs per unit length. When analyzing budget constraints for aerospace or medical applications, selecting titanium wire can offer a more cost-effective solution without compromising strength and corrosion resistance.

Selecting the Right Titanium Form for Your Project

Choosing between titanium bar and titanium wire depends on the specific requirements of your project, including strength, flexibility, and machining needs. Titanium bars offer superior rigidity and are ideal for structural components requiring precise machining and high strength-to-weight ratios. Titanium wires provide enhanced flexibility and are better suited for applications involving intricate shapes, springs, or electrical conductors where tensile strength and conductivity are crucial.

Summary: Titanium Bar vs Wire

Titanium bars offer superior strength, rigidity, and bulk material ideal for machining and structural applications, while titanium wires provide flexibility, high tensile strength, and suitability for intricate fabrication and medical uses. The density of titanium bars typically ranges around 4.43 g/cm3, with enhanced machinability, whereas titanium wires emphasize minimal cross-sectional areas for precise engineering demands. Choosing between titanium bar and wire depends on application requirements such as mechanical load, formability, and surface finish.

Titanium Bar vs Titanium Wire Infographic

materialdif.com

materialdif.com