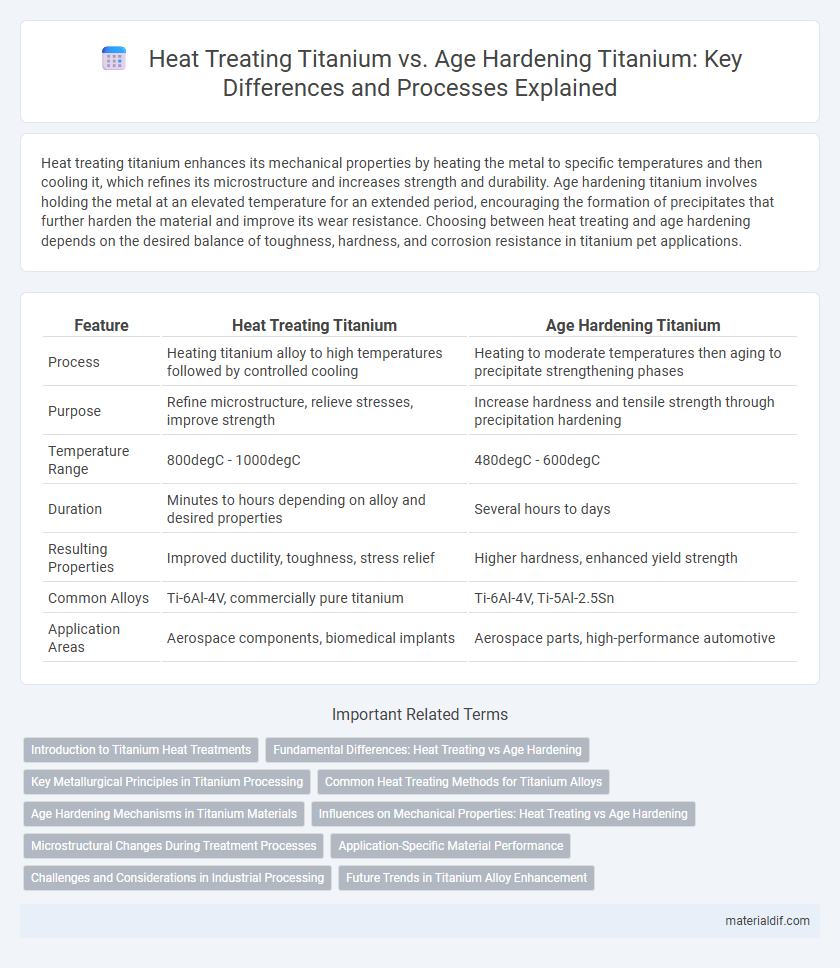

Heat treating titanium enhances its mechanical properties by heating the metal to specific temperatures and then cooling it, which refines its microstructure and increases strength and durability. Age hardening titanium involves holding the metal at an elevated temperature for an extended period, encouraging the formation of precipitates that further harden the material and improve its wear resistance. Choosing between heat treating and age hardening depends on the desired balance of toughness, hardness, and corrosion resistance in titanium pet applications.

Table of Comparison

| Feature | Heat Treating Titanium | Age Hardening Titanium |

|---|---|---|

| Process | Heating titanium alloy to high temperatures followed by controlled cooling | Heating to moderate temperatures then aging to precipitate strengthening phases |

| Purpose | Refine microstructure, relieve stresses, improve strength | Increase hardness and tensile strength through precipitation hardening |

| Temperature Range | 800degC - 1000degC | 480degC - 600degC |

| Duration | Minutes to hours depending on alloy and desired properties | Several hours to days |

| Resulting Properties | Improved ductility, toughness, stress relief | Higher hardness, enhanced yield strength |

| Common Alloys | Ti-6Al-4V, commercially pure titanium | Ti-6Al-4V, Ti-5Al-2.5Sn |

| Application Areas | Aerospace components, biomedical implants | Aerospace parts, high-performance automotive |

Introduction to Titanium Heat Treatments

Heat treating titanium involves processes like annealing and solution treating to enhance its mechanical properties by altering microstructure. Age hardening titanium, also known as precipitation hardening, focuses on the controlled formation of fine precipitates to increase strength and hardness over time. Both treatments optimize titanium's performance for aerospace, medical, and industrial applications by balancing ductility and tensile strength.

Fundamental Differences: Heat Treating vs Age Hardening

Heat treating titanium involves controlled heating and cooling to alter its microstructure, enhancing properties like strength and toughness by relieving internal stresses. Age hardening titanium specifically relies on precipitation mechanisms where alloys are heated to a solutionizing temperature, quenched, and then aged at lower temperatures to form fine precipitates that increase hardness and strength. The fundamental difference lies in heat treating broadly modifying microstructures through thermal cycles, while age hardening precisely induces phase transformations for targeted property enhancement.

Key Metallurgical Principles in Titanium Processing

Heat treating titanium involves controlled heating and cooling to alter its microstructure, enhancing properties like strength and ductility through phase transformations between alpha and beta phases. Age hardening titanium relies on precipitation strengthening, where fine particles form within the titanium matrix during aging, increasing hardness and tensile strength without significantly changing ductility. Understanding the diffusion rates, phase stability, and solvus temperatures of alloying elements is crucial for optimizing both heat treating and age hardening processes in titanium metallurgy.

Common Heat Treating Methods for Titanium Alloys

Common heat treating methods for titanium alloys include solution treating and aging, annealing, and stress relieving, each tailored to enhance mechanical properties and corrosion resistance. Solution treating involves heating the alloy to a high temperature followed by rapid cooling to create a homogeneous microstructure, while age hardening (precipitation hardening) promotes fine precipitate formation to increase strength and hardness. Annealing reduces residual stresses and improves ductility, making these processes essential for optimizing titanium alloy performance in aerospace, medical, and industrial applications.

Age Hardening Mechanisms in Titanium Materials

Age hardening in titanium alloys involves the precipitation of fine intermetallic phases, such as Ti3Al, which significantly enhance strength and hardness by impeding dislocation motion. This process typically follows solution treatment and quenching, where controlled aging promotes the nucleation and growth of coherent precipitates within the a or b phases. Compared to conventional heat treating, age hardening leverages precise thermal cycles to optimize microstructural evolution, resulting in superior mechanical properties tailored for aerospace and biomedical applications.

Influences on Mechanical Properties: Heat Treating vs Age Hardening

Heat treating titanium involves controlled heating and cooling cycles that enhance its strength and ductility by refining the microstructure and relieving residual stresses. Age hardening titanium relies on precipitation strengthening, where fine particles form within the alloy matrix over time at specific temperatures, significantly increasing hardness and tensile strength. The mechanical properties differ as heat treating improves toughness and formability, while age hardening primarily boosts yield strength and hardness through microstructural evolution.

Microstructural Changes During Treatment Processes

Heat treating titanium primarily involves solution treating and quenching, which dissolves precipitates and creates a supersaturated solid solution, refining the grain structure for improved strength and ductility. Age hardening titanium induces the controlled precipitation of secondary phases like Ti3Al within the alpha matrix, enhancing hardness and tensile properties through fine-scale microstructural adjustments. These microstructural changes tailor the mechanical behavior by balancing phase stability, precipitate distribution, and grain size during the respective treatment processes.

Application-Specific Material Performance

Heat treating titanium enhances its tensile strength and corrosion resistance, making it ideal for aerospace components exposed to high stress and temperature fluctuations. Age hardening titanium improves fatigue life and wear resistance, which is crucial for biomedical implants requiring long-term durability and biocompatibility. Selecting between heat treating and age hardening depends on the specific performance demands of applications such as aircraft structural parts or orthopedic devices.

Challenges and Considerations in Industrial Processing

Heat treating titanium involves precise control of temperature and atmosphere to prevent oxidation and maintain mechanical properties, presenting challenges such as warping and grain growth. Age hardening titanium requires careful timing and temperature management to optimize precipitation strengthening without compromising ductility. Industrial processing must consider alloy composition, cooling rates, and furnace atmosphere to balance strength, toughness, and corrosion resistance effectively.

Future Trends in Titanium Alloy Enhancement

Future trends in titanium alloy enhancement focus on advanced heat treating techniques and age hardening processes to optimize strength and corrosion resistance. Innovative heat treatments utilize precise temperature controls and cooling rates to refine microstructures, enhancing mechanical properties. Age hardening, through controlled precipitation of secondary phases, is expected to enable more uniform and higher-strength titanium alloys for aerospace and biomedical applications.

Heat Treating Titanium vs Age Hardening Titanium Infographic

materialdif.com

materialdif.com