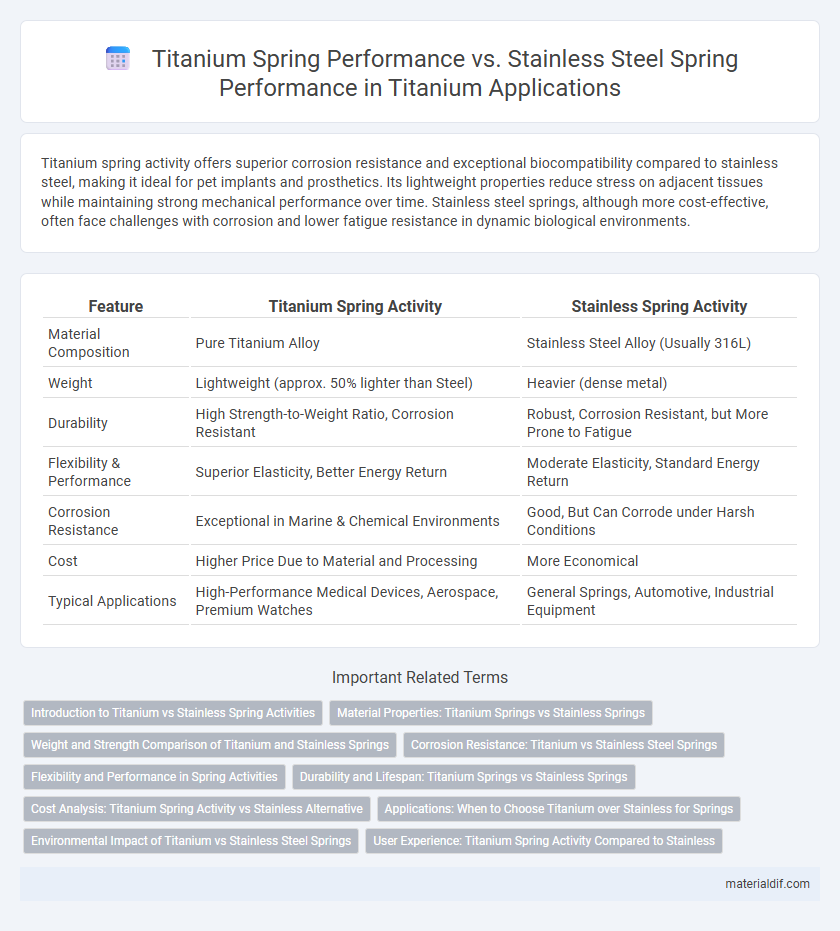

Titanium spring activity offers superior corrosion resistance and exceptional biocompatibility compared to stainless steel, making it ideal for pet implants and prosthetics. Its lightweight properties reduce stress on adjacent tissues while maintaining strong mechanical performance over time. Stainless steel springs, although more cost-effective, often face challenges with corrosion and lower fatigue resistance in dynamic biological environments.

Table of Comparison

| Feature | Titanium Spring Activity | Stainless Spring Activity |

|---|---|---|

| Material Composition | Pure Titanium Alloy | Stainless Steel Alloy (Usually 316L) |

| Weight | Lightweight (approx. 50% lighter than Steel) | Heavier (dense metal) |

| Durability | High Strength-to-Weight Ratio, Corrosion Resistant | Robust, Corrosion Resistant, but More Prone to Fatigue |

| Flexibility & Performance | Superior Elasticity, Better Energy Return | Moderate Elasticity, Standard Energy Return |

| Corrosion Resistance | Exceptional in Marine & Chemical Environments | Good, But Can Corrode under Harsh Conditions |

| Cost | Higher Price Due to Material and Processing | More Economical |

| Typical Applications | High-Performance Medical Devices, Aerospace, Premium Watches | General Springs, Automotive, Industrial Equipment |

Introduction to Titanium vs Stainless Spring Activities

Titanium spring activity surpasses stainless steel in corrosion resistance, especially in marine and chemical environments, due to its robust oxide layer. Titanium alloys exhibit a high strength-to-weight ratio, making them ideal for applications requiring lightweight, durable springs. Stainless steel springs offer good mechanical properties and cost-effectiveness but typically fall short in extreme performance scenarios compared to titanium springs.

Material Properties: Titanium Springs vs Stainless Springs

Titanium springs exhibit superior corrosion resistance and a higher strength-to-weight ratio compared to stainless steel springs, making them ideal for aerospace and medical applications where weight savings and durability are critical. The elasticity modulus of titanium allows for a wider operational temperature range without significant loss of spring tension, unlike stainless steel which can experience reduced performance in extreme environments. Titanium's biocompatibility and resistance to fatigue enhance the longevity of springs under cyclic loads, whereas stainless steel may suffer from stress corrosion cracking over time.

Weight and Strength Comparison of Titanium and Stainless Springs

Titanium springs offer a significant weight advantage, being approximately 40% lighter than stainless steel springs while maintaining comparable tensile strength. The high strength-to-weight ratio of titanium makes it ideal for applications requiring reduced mass without sacrificing durability. Stainless steel springs provide excellent corrosion resistance and toughness but are heavier, which can be a limitation in weight-sensitive designs.

Corrosion Resistance: Titanium vs Stainless Steel Springs

Titanium springs exhibit superior corrosion resistance compared to stainless steel springs due to the formation of a stable and protective oxide layer that prevents rust and chemical degradation. In aggressive environments such as marine or chemical exposure, titanium maintains structural integrity without pitting or crevice corrosion that commonly affects stainless steel. This inherent corrosion resistance extends the longevity and reliability of titanium springs in demanding applications where stainless steel would require frequent replacement or protective coatings.

Flexibility and Performance in Spring Activities

Titanium exhibits superior spring activity compared to stainless steel due to its high strength-to-weight ratio and exceptional elasticity, enabling greater flexibility in dynamic applications. The enhanced springback performance of titanium alloys allows for repetitive deformation without permanent set, making them ideal for precision components in aerospace and medical devices. Stainless steel, while durable and corrosion-resistant, typically offers lower flexibility and reduced fatigue life under cyclic loading conditions relative to titanium springs.

Durability and Lifespan: Titanium Springs vs Stainless Springs

Titanium springs exhibit superior durability and extended lifespan compared to stainless steel springs due to their high corrosion resistance and excellent fatigue strength. While stainless springs offer good mechanical properties, titanium's lightweight composition and exceptional resistance to environmental wear enhance longevity in demanding applications. This makes titanium springs ideal for industrial and aerospace uses where long-term reliability is critical.

Cost Analysis: Titanium Spring Activity vs Stainless Alternative

Titanium spring activity offers superior corrosion resistance and a longer lifespan compared to stainless steel alternatives, justifying its higher initial cost in long-term applications. Stainless steel springs are more cost-effective upfront but may incur increased maintenance and replacement expenses due to susceptibility to corrosion and fatigue. Evaluating total cost of ownership reveals titanium as the optimal choice for high-performance, durability-critical environments despite the premium price.

Applications: When to Choose Titanium over Stainless for Springs

Titanium springs excel in aerospace, medical devices, and marine applications due to their superior corrosion resistance, high strength-to-weight ratio, and excellent fatigue life compared to stainless steel springs. Selecting titanium over stainless steel is crucial in environments exposed to saltwater or extreme temperatures, where stainless springs may corrode or lose elasticity. Titanium's biocompatibility and lightweight properties make it ideal for implantable medical springs and weight-sensitive aerospace components.

Environmental Impact of Titanium vs Stainless Steel Springs

Titanium springs demonstrate a significantly lower environmental impact compared to stainless steel springs due to their enhanced corrosion resistance, which reduces the need for frequent replacements and waste. The extraction and processing of titanium consume less energy and produce fewer greenhouse gas emissions than stainless steel manufacturing. Additionally, titanium's superior recyclability and longer lifespan contribute to reduced resource depletion and minimized ecological footprint in various industrial applications.

User Experience: Titanium Spring Activity Compared to Stainless

Titanium spring activity outperforms stainless steel by offering greater elasticity and resilience, ensuring enhanced comfort and durability in applications like eyewear frames and medical devices. Users experience less fatigue due to titanium's superior strength-to-weight ratio, combined with exceptional corrosion resistance that maintains performance over time. This results in a more reliable and comfortable user experience, especially in demanding environments.

Titanium Spring Activity vs Stainless Spring Activity Infographic

materialdif.com

materialdif.com