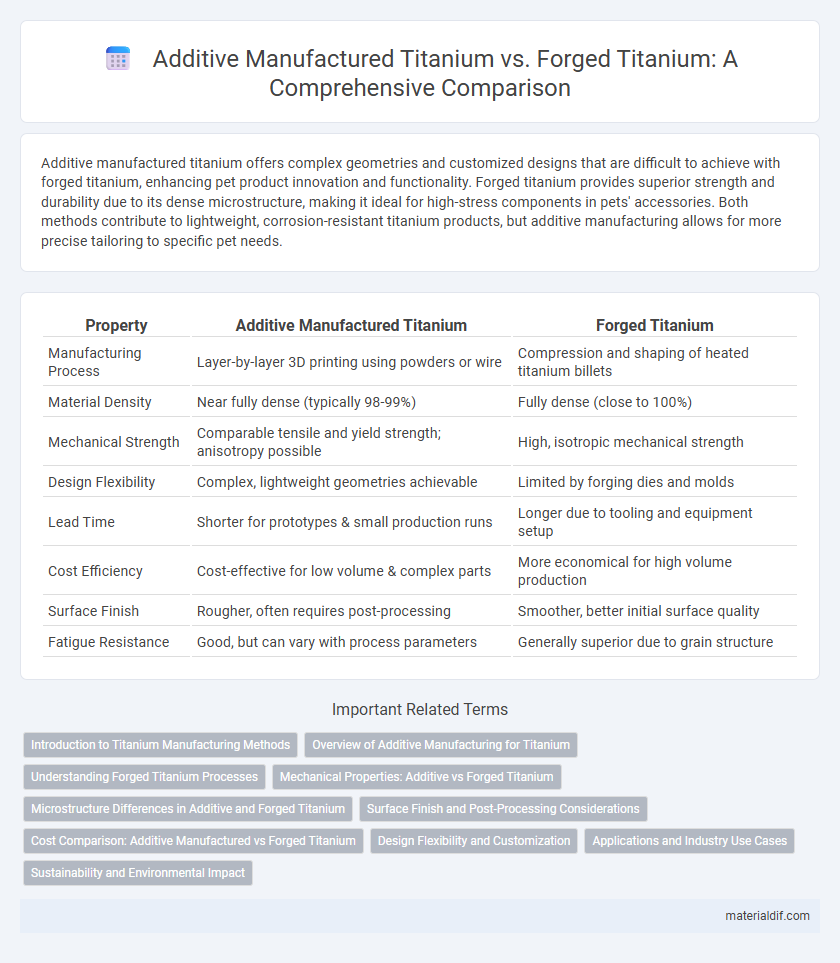

Additive manufactured titanium offers complex geometries and customized designs that are difficult to achieve with forged titanium, enhancing pet product innovation and functionality. Forged titanium provides superior strength and durability due to its dense microstructure, making it ideal for high-stress components in pets' accessories. Both methods contribute to lightweight, corrosion-resistant titanium products, but additive manufacturing allows for more precise tailoring to specific pet needs.

Table of Comparison

| Property | Additive Manufactured Titanium | Forged Titanium |

|---|---|---|

| Manufacturing Process | Layer-by-layer 3D printing using powders or wire | Compression and shaping of heated titanium billets |

| Material Density | Near fully dense (typically 98-99%) | Fully dense (close to 100%) |

| Mechanical Strength | Comparable tensile and yield strength; anisotropy possible | High, isotropic mechanical strength |

| Design Flexibility | Complex, lightweight geometries achievable | Limited by forging dies and molds |

| Lead Time | Shorter for prototypes & small production runs | Longer due to tooling and equipment setup |

| Cost Efficiency | Cost-effective for low volume & complex parts | More economical for high volume production |

| Surface Finish | Rougher, often requires post-processing | Smoother, better initial surface quality |

| Fatigue Resistance | Good, but can vary with process parameters | Generally superior due to grain structure |

Introduction to Titanium Manufacturing Methods

Additive manufactured titanium offers complex geometries and reduced material waste by building parts layer-by-layer using techniques such as selective laser melting, while forged titanium provides superior mechanical properties and structural integrity through controlled deformation processes. Both methods utilize grade 5 titanium alloy (Ti-6Al-4V) extensively in aerospace and biomedical industries due to its strength-to-weight ratio and corrosion resistance. Understanding the differences in microstructure and mechanical performance between additive manufacturing and forging is crucial for optimizing titanium component design and application.

Overview of Additive Manufacturing for Titanium

Additive manufacturing of titanium utilizes layer-by-layer deposition of titanium powders through processes such as selective laser melting (SLM) or electron beam melting (EBM) to create complex geometries with high precision and minimal material waste. This method enables the production of lightweight, intricate titanium components with tailored mechanical properties that are difficult to achieve using traditional forging techniques. Compared to forged titanium, additive manufacturing offers enhanced design flexibility, reduced lead times, and the potential for custom implants and aerospace parts with optimized strength-to-weight ratios.

Understanding Forged Titanium Processes

Forged titanium involves shaping metal through compressive forces applied via dies or hammers, resulting in a dense microstructure with enhanced mechanical properties such as superior strength and fatigue resistance. This process promotes grain refinement and reduces porosity compared to additive manufacturing, making forged titanium ideal for critical aerospace and biomedical applications. Understanding the thermal and mechanical parameters in forging helps optimize the titanium's performance, ensuring reliability in high-stress environments.

Mechanical Properties: Additive vs Forged Titanium

Additive manufactured titanium exhibits a unique microstructure with typically higher porosity and anisotropy compared to forged titanium, which results in varied mechanical properties such as tensile strength and fatigue resistance. Forged titanium generally demonstrates superior ductility and toughness due to its homogeneous grain structure, providing enhanced performance under cyclic loading and impact conditions. Despite advancements in additive manufacturing technology, forged titanium remains the preferred choice for critical aerospace and biomedical applications requiring consistent mechanical reliability.

Microstructure Differences in Additive and Forged Titanium

Additive manufactured titanium exhibits a unique microstructure characterized by fine, columnar prior beta grains with acicular alpha prime martensite due to rapid cooling rates in laser powder bed fusion processes. Forged titanium, in contrast, typically shows equiaxed or lamellar alpha grains formed under controlled thermomechanical processing, resulting in more uniform and coarse microstructures. These microstructural differences significantly influence mechanical properties such as strength, ductility, and fatigue resistance in aerospace and biomedical applications.

Surface Finish and Post-Processing Considerations

Additive manufactured titanium typically presents a rougher surface finish due to layer-by-layer fabrication, requiring extensive post-processing such as machining or polishing to meet aerospace or medical standards. Forged titanium generally features a smoother surface finish directly from the forging process, reducing the need for intensive post-processing and enhancing fatigue resistance. Surface finish quality directly impacts corrosion resistance and mechanical performance, making post-processing considerations critical in selecting between both manufacturing methods.

Cost Comparison: Additive Manufactured vs Forged Titanium

Additive manufactured titanium typically incurs higher initial costs due to advanced 3D printing technology and slower production speeds, but it offers reduced material waste and lower tooling expenses compared to forged titanium. Forged titanium benefits from established mass production techniques and faster throughput, resulting in lower per-unit costs for large volume orders. Cost efficiency varies significantly depending on production scale, complexity of design, and material usage in additive versus forged titanium manufacturing.

Design Flexibility and Customization

Additive manufactured titanium offers superior design flexibility and customization by enabling complex geometries and tailored structures unachievable through traditional forging methods. This technology allows precise control over material distribution and internal features, optimizing strength-to-weight ratios for specialized applications. Forged titanium, while providing excellent mechanical properties, is limited in design complexity and customization compared to additive manufacturing.

Applications and Industry Use Cases

Additive manufactured titanium offers complex geometries and lightweight designs ideal for aerospace components like turbine blades and medical implants requiring custom shapes and rapid prototyping. Forged titanium provides superior strength and fatigue resistance, making it the preferred choice for critical structural parts in aerospace, automotive, and defense industries where durability and reliability are crucial. Both manufacturing methods enable titanium's widespread use across sectors like biomedical devices, industrial equipment, and high-performance sporting goods.

Sustainability and Environmental Impact

Additive manufactured titanium significantly reduces material waste by utilizing precise layer-by-layer construction, offering enhanced sustainability compared to traditional forged titanium, which often results in substantial offcuts and scrap. The lower energy consumption during the additive manufacturing process coupled with the potential for on-demand production minimizes carbon emissions and inventory waste, further decreasing environmental impact. Lifecycle assessments reveal that additive manufacturing supports circular economy principles through efficient resource use and recyclability, making it a more eco-friendly choice in titanium fabrication.

Additive Manufactured Titanium vs Forged Titanium Infographic

materialdif.com

materialdif.com