Machined titanium offers superior strength and precision by cutting from a solid block, resulting in denser and more durable pet components. Sintered titanium, created by fusing titanium powder under high heat and pressure, provides lightweight and complex shapes but may have slightly reduced strength. Choosing machined titanium ensures enhanced performance and longevity for high-stress pet applications.

Table of Comparison

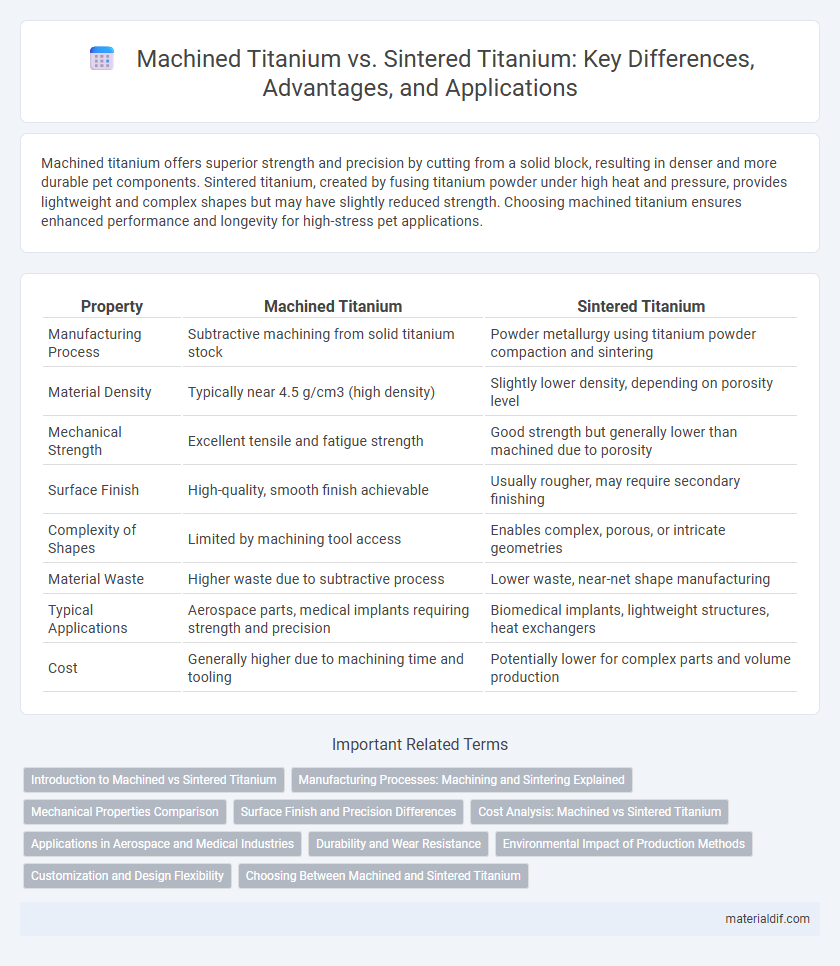

| Property | Machined Titanium | Sintered Titanium |

|---|---|---|

| Manufacturing Process | Subtractive machining from solid titanium stock | Powder metallurgy using titanium powder compaction and sintering |

| Material Density | Typically near 4.5 g/cm3 (high density) | Slightly lower density, depending on porosity level |

| Mechanical Strength | Excellent tensile and fatigue strength | Good strength but generally lower than machined due to porosity |

| Surface Finish | High-quality, smooth finish achievable | Usually rougher, may require secondary finishing |

| Complexity of Shapes | Limited by machining tool access | Enables complex, porous, or intricate geometries |

| Material Waste | Higher waste due to subtractive process | Lower waste, near-net shape manufacturing |

| Typical Applications | Aerospace parts, medical implants requiring strength and precision | Biomedical implants, lightweight structures, heat exchangers |

| Cost | Generally higher due to machining time and tooling | Potentially lower for complex parts and volume production |

Introduction to Machined vs Sintered Titanium

Machined titanium is produced by precisely cutting and shaping solid titanium blocks using CNC machines, offering high dimensional accuracy and superior surface finish. Sintered titanium is created through powder metallurgy, where titanium powder is compressed and heated below its melting point to form a solid part, enabling complex geometries and cost-efficient production. Machined titanium typically provides greater mechanical strength and consistency compared to sintered titanium, which excels in applications requiring lightweight and intricate designs.

Manufacturing Processes: Machining and Sintering Explained

Machined titanium involves the subtractive manufacturing process where a solid titanium billet is precisely cut and shaped using CNC machines, offering high dimensional accuracy and surface finish. Sintered titanium is produced through powder metallurgy, where titanium powder is compacted and heated below its melting point to form a solid part, allowing for complex geometries and reduced material waste. Machining excels in tight tolerances and smooth finishes, while sintering is advantageous for cost-effective mass production and intricate design features.

Mechanical Properties Comparison

Machined titanium exhibits superior tensile strength and fatigue resistance compared to sintered titanium, making it ideal for high-stress applications in aerospace and medical implants. Sintered titanium typically shows enhanced porosity and lower density, which benefits bone ingrowth and osseointegration but results in reduced mechanical robustness. The choice between machined and sintered titanium depends on balancing mechanical performance with biological compatibility requirements.

Surface Finish and Precision Differences

Machined titanium exhibits superior surface finish and dimensional precision due to its subtractive manufacturing process, which allows for intricate detailing and tight tolerance control. Sintered titanium, produced through powder metallurgy, often has a rougher surface texture and slightly less precise dimensions due to the nature of powder compaction and sintering shrinkage. Precision-driven applications favor machined titanium for its smooth finish and accuracy, while sintered titanium benefits cost-effective production with moderate precision.

Cost Analysis: Machined vs Sintered Titanium

Machined titanium involves subtractive manufacturing, where material is precisely cut from a solid billet, resulting in higher labor and material waste costs but superior mechanical properties and surface finish. Sintered titanium, created through powder metallurgy and sintering, offers cost efficiencies by minimizing material waste and enabling complex geometries but may exhibit lower density and mechanical strength. Cost analysis reveals that machined titanium is more expensive upfront due to machining time and tooling, while sintered titanium reduces manufacturing expenses but might require post-processing to meet performance standards.

Applications in Aerospace and Medical Industries

Machined titanium offers superior strength and precision for aerospace components such as turbine blades and structural parts, ensuring high performance under extreme conditions. Sintered titanium, produced through powder metallurgy, provides excellent porosity control and lightweight properties ideal for medical implants like dental and orthopedic devices. Both methods leverage titanium's biocompatibility and corrosion resistance, but machined titanium is preferred where dimensional accuracy and mechanical integrity are critical, while sintered titanium allows complex geometries and cost-effective mass production.

Durability and Wear Resistance

Machined titanium exhibits superior durability and wear resistance due to its dense, homogeneous microstructure formed through subtractive manufacturing processes. Sintered titanium often contains microscopic porosities and inconsistencies from powder metallurgy, which can reduce its mechanical strength and increase susceptibility to wear. Consequently, machined titanium is preferred in high-stress applications requiring long-term performance and minimal material degradation.

Environmental Impact of Production Methods

Machined titanium involves subtractive manufacturing, producing significant metal waste and consuming high energy during cutting and finishing processes. Sintered titanium utilizes powder metallurgy, reducing material waste and often requiring lower energy inputs compared to machining, leading to a smaller carbon footprint. Evaluating production methods, sintered titanium generally presents a more environmentally sustainable option due to minimized raw material loss and improved energy efficiency.

Customization and Design Flexibility

Machined titanium offers precise customization through CNC milling, enabling intricate designs with tight tolerances suitable for aerospace and medical implants. Sintered titanium provides enhanced design flexibility by allowing complex geometries and porous structures via additive manufacturing techniques like powder bed fusion. This makes sintered titanium ideal for lightweight, structurally optimized parts that are difficult to achieve through traditional machining.

Choosing Between Machined and Sintered Titanium

Choosing between machined titanium and sintered titanium depends on specific application requirements such as strength, precision, and cost. Machined titanium offers superior dimensional accuracy and surface finish, making it ideal for aerospace and medical components requiring tight tolerances. Sintered titanium, produced via powder metallurgy, provides cost-effective manufacturing and complex geometries but may have lower mechanical properties compared to machined counterparts.

Machined Titanium vs Sintered Titanium Infographic

materialdif.com

materialdif.com