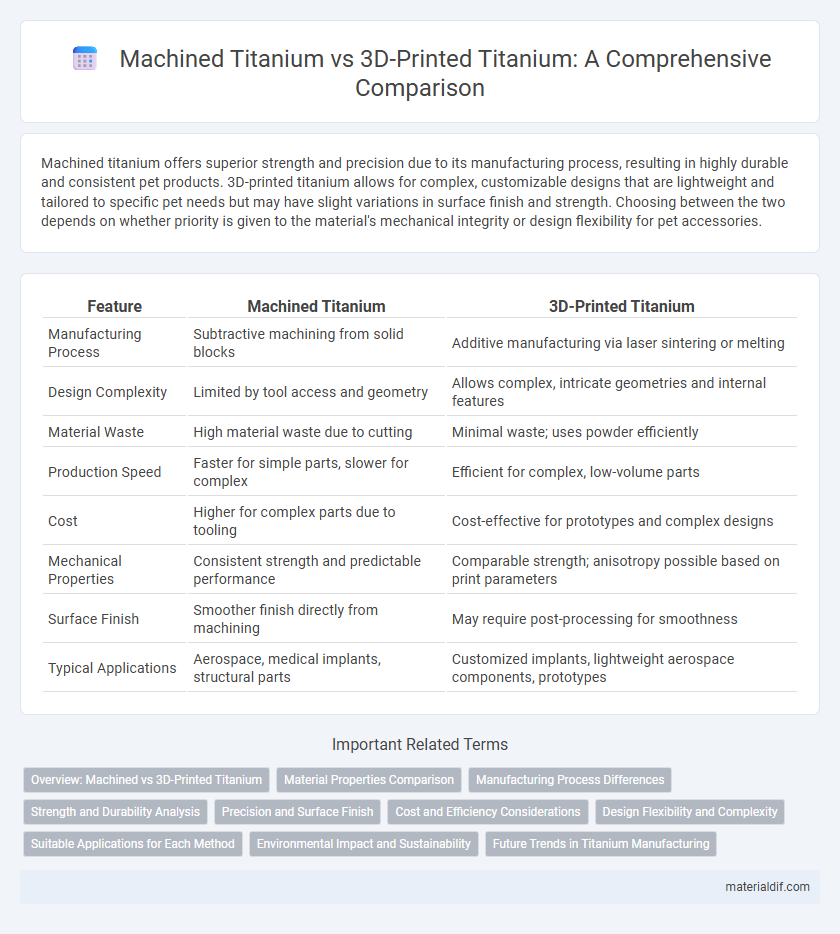

Machined titanium offers superior strength and precision due to its manufacturing process, resulting in highly durable and consistent pet products. 3D-printed titanium allows for complex, customizable designs that are lightweight and tailored to specific pet needs but may have slight variations in surface finish and strength. Choosing between the two depends on whether priority is given to the material's mechanical integrity or design flexibility for pet accessories.

Table of Comparison

| Feature | Machined Titanium | 3D-Printed Titanium |

|---|---|---|

| Manufacturing Process | Subtractive machining from solid blocks | Additive manufacturing via laser sintering or melting |

| Design Complexity | Limited by tool access and geometry | Allows complex, intricate geometries and internal features |

| Material Waste | High material waste due to cutting | Minimal waste; uses powder efficiently |

| Production Speed | Faster for simple parts, slower for complex | Efficient for complex, low-volume parts |

| Cost | Higher for complex parts due to tooling | Cost-effective for prototypes and complex designs |

| Mechanical Properties | Consistent strength and predictable performance | Comparable strength; anisotropy possible based on print parameters |

| Surface Finish | Smoother finish directly from machining | May require post-processing for smoothness |

| Typical Applications | Aerospace, medical implants, structural parts | Customized implants, lightweight aerospace components, prototypes |

Overview: Machined vs 3D-Printed Titanium

Machined titanium involves subtractive manufacturing where material is precisely removed from a solid block, offering superior surface finish and tight tolerances ideal for aerospace and medical components. 3D-printed titanium, created via additive manufacturing techniques like selective laser melting, enables complex geometries and lightweight lattice structures unattainable through traditional methods. While machined titanium excels in strength and dimensional accuracy, 3D-printed titanium provides design flexibility and material efficiency critical for innovative engineering applications.

Material Properties Comparison

Machined titanium offers superior surface finish and dimensional accuracy due to subtractive manufacturing processes, ensuring high fatigue resistance and predictable mechanical properties. 3D-printed titanium, produced via additive manufacturing, provides intricate geometries and material efficiency but may exhibit anisotropic strength and higher porosity, potentially affecting fatigue life. Both methods utilize Ti-6Al-4V alloy, though post-processing treatments are crucial in 3D-printed titanium to enhance microstructure and mechanical performance to match machined counterparts.

Manufacturing Process Differences

Machined titanium is produced by subtractive manufacturing, where a solid titanium block is precisely carved using CNC machines to achieve the desired shape, ensuring high accuracy and smooth surface finishes. In contrast, 3D-printed titanium utilizes additive manufacturing techniques like selective laser melting (SLM) or electron beam melting (EBM) to build components layer by layer, allowing for complex geometries and lightweight structures. The machining process typically results in less material waste but is limited in design flexibility, whereas 3D printing enables intricate internal features but may require post-processing to enhance surface quality and mechanical properties.

Strength and Durability Analysis

Machined titanium exhibits superior strength due to its uniform grain structure achieved through subtractive manufacturing, resulting in consistent mechanical properties and higher fatigue resistance. 3D-printed titanium, while offering complex geometries and material efficiency, may present anisotropic strength and microstructural inconsistencies affecting its overall durability. Advanced post-processing techniques such as hot isostatic pressing (HIP) can enhance the strength and longevity of 3D-printed titanium to more closely match that of machined counterparts.

Precision and Surface Finish

Machined titanium offers superior precision with tight tolerances typically within +-0.01 mm, providing smooth surface finishes ideal for aerospace and medical components. In contrast, 3D-printed titanium parts often require post-processing due to inherent layer lines and rough textures, achieving surface finishes around Ra 3-10 um before secondary treatments. Advanced machining ensures consistent dimensional accuracy, whereas additive manufacturing excels in complex geometries but typically demands additional polishing for optimal surface quality.

Cost and Efficiency Considerations

Machined titanium involves subtractive manufacturing, leading to higher material waste and increased labor costs compared to 3D-printed titanium, which uses additive manufacturing to optimize material usage and reduce production times. 3D printing enables complex geometries and rapid prototyping with lower upfront tooling costs, while machined titanium remains more cost-effective for large-scale production runs with simpler designs. Evaluating cost efficiency depends on production volume, design complexity, and required mechanical properties, with 3D printing offering advantages in customization and lead time reduction.

Design Flexibility and Complexity

Machined titanium offers precise control for creating parts with smooth finishes and tight tolerances, making it ideal for simpler, symmetrical designs. In contrast, 3D-printed titanium enables unparalleled design flexibility, allowing for complex geometries, internal channels, and lattice structures that are impossible or costly with traditional machining. This additive manufacturing process unlocks advanced customization options and lightweight optimization for aerospace, medical implants, and high-performance engineering applications.

Suitable Applications for Each Method

Machined titanium excels in applications requiring high precision and smooth surface finishes, such as aerospace components, surgical instruments, and custom prosthetics. 3D-printed titanium offers advantages in complex geometries, lightweight structures, and rapid prototyping, making it ideal for aerospace lattice structures, medical implants with porous architecture, and intricate automotive parts. Each method suits different production needs, with machining preferred for tight tolerances and 3D printing favored for design flexibility and material efficiency.

Environmental Impact and Sustainability

Machined titanium generates significant waste due to subtractive manufacturing, where excess metal is cut away and often discarded, increasing material consumption and environmental footprint. In contrast, 3D-printed titanium promotes sustainability by using additive manufacturing, which deposits material layer-by-layer, minimizing waste and enabling lightweight designs that reduce energy use in applications. The reduced scrappage and optimized material usage in 3D printing contribute to lower carbon emissions and enhanced resource efficiency in titanium production.

Future Trends in Titanium Manufacturing

Machined titanium remains a benchmark for precision and surface finish in aerospace and medical industries, but 3D-printed titanium is rapidly advancing with innovations in additive manufacturing techniques such as selective laser melting (SLM) and electron beam melting (EBM). Future trends emphasize hybrid manufacturing processes combining machining and 3D printing to optimize mechanical properties, reduce material waste, and enable complex geometries previously unattainable with conventional methods. Industry forecasts predict increased adoption of AI-driven process controls and real-time monitoring to enhance part consistency, significantly expanding titanium's applications in lightweight structures and custom implants.

Machined Titanium vs 3D-Printed Titanium Infographic

materialdif.com

materialdif.com