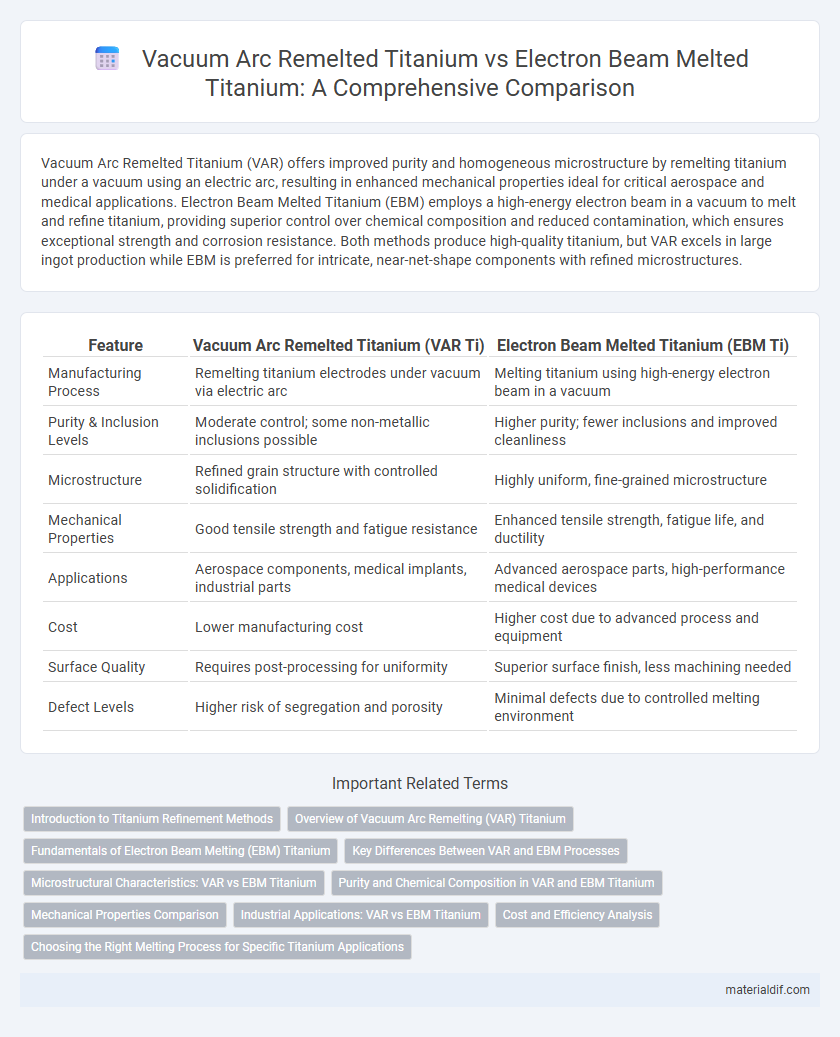

Vacuum Arc Remelted Titanium (VAR) offers improved purity and homogeneous microstructure by remelting titanium under a vacuum using an electric arc, resulting in enhanced mechanical properties ideal for critical aerospace and medical applications. Electron Beam Melted Titanium (EBM) employs a high-energy electron beam in a vacuum to melt and refine titanium, providing superior control over chemical composition and reduced contamination, which ensures exceptional strength and corrosion resistance. Both methods produce high-quality titanium, but VAR excels in large ingot production while EBM is preferred for intricate, near-net-shape components with refined microstructures.

Table of Comparison

| Feature | Vacuum Arc Remelted Titanium (VAR Ti) | Electron Beam Melted Titanium (EBM Ti) |

|---|---|---|

| Manufacturing Process | Remelting titanium electrodes under vacuum via electric arc | Melting titanium using high-energy electron beam in a vacuum |

| Purity & Inclusion Levels | Moderate control; some non-metallic inclusions possible | Higher purity; fewer inclusions and improved cleanliness |

| Microstructure | Refined grain structure with controlled solidification | Highly uniform, fine-grained microstructure |

| Mechanical Properties | Good tensile strength and fatigue resistance | Enhanced tensile strength, fatigue life, and ductility |

| Applications | Aerospace components, medical implants, industrial parts | Advanced aerospace parts, high-performance medical devices |

| Cost | Lower manufacturing cost | Higher cost due to advanced process and equipment |

| Surface Quality | Requires post-processing for uniformity | Superior surface finish, less machining needed |

| Defect Levels | Higher risk of segregation and porosity | Minimal defects due to controlled melting environment |

Introduction to Titanium Refinement Methods

Vacuum Arc Remelting (VAR) and Electron Beam Melting (EBM) are advanced titanium refinement methods used to improve metal purity and structural properties. VAR utilizes a controlled vacuum environment to remelt titanium ingots, reducing impurities such as oxygen, nitrogen, and hydrogen while enhancing grain structure. EBM employs a high-energy electron beam in a vacuum to refine titanium, offering superior control over the melting process and resulting in improved homogeneity and mechanical properties.

Overview of Vacuum Arc Remelting (VAR) Titanium

Vacuum Arc Remelting (VAR) titanium is produced by remelting a consumable electrode in a vacuum chamber to ensure high purity and homogeneity in the metal. This process significantly reduces impurities such as gases and inclusions, improving mechanical properties and fatigue resistance compared to standard titanium melts. VAR titanium is favored in aerospace and medical applications where superior strength, toughness, and corrosion resistance are critical.

Fundamentals of Electron Beam Melting (EBM) Titanium

Electron Beam Melting (EBM) titanium involves melting titanium alloy powders under a high-energy electron beam in a vacuum, enabling precise control of temperature and solidification rates to produce dense, defect-free components. EBM allows for complex geometries and fine microstructural control by selectively melting powder layers, which enhances mechanical properties and reduces internal stresses compared to Vacuum Arc Remelted (VAR) titanium. The vacuum environment in EBM minimizes contamination and oxidation, ensuring high-purity titanium parts ideal for aerospace and medical applications.

Key Differences Between VAR and EBM Processes

Vacuum Arc Remelted (VAR) titanium is produced by melting titanium electrodes in a vacuum using an electric arc, resulting in improved purity and reduced gas content, which enhances mechanical properties and structural integrity. Electron Beam Melted (EBM) titanium uses a focused electron beam to melt titanium powder layer by layer in a vacuum, allowing for precise control over microstructure and complex geometries with lower residual stress. Key differences include VAR's bulk melting approach suited for large ingots, while EBM excels in additive manufacturing with higher design flexibility and refined microstructural control.

Microstructural Characteristics: VAR vs EBM Titanium

Vacuum Arc Remelted (VAR) titanium exhibits a refined, more homogeneous microstructure with reduced segregation and lower porosity compared to Electron Beam Melted (EBM) titanium, which often shows larger grain sizes and higher anisotropy due to layer-by-layer solidification. VAR titanium typically features a dendritic microstructure with uniform grain orientation, enhancing mechanical properties and fatigue resistance. In contrast, EBM titanium's microstructure reflects rapid cooling rates and directional solidification, resulting in heterogeneous grain morphology and distinct columnar grain growth.

Purity and Chemical Composition in VAR and EBM Titanium

Vacuum Arc Remelted (VAR) titanium exhibits superior chemical homogeneity and reduced gas content, leading to enhanced purity compared to Electron Beam Melted (EBM) titanium, which can have higher oxygen and nitrogen levels due to less effective vacuum control. VAR titanium typically maintains tighter control over trace elements and interstitial impurities, resulting in consistent mechanical properties and corrosion resistance. EBM titanium, while offering near-net shape capabilities, may require additional post-processing to match the purity and chemical composition standards achieved by VAR processes.

Mechanical Properties Comparison

Vacuum Arc Remelted (VAR) titanium exhibits superior mechanical properties such as higher tensile strength and improved fatigue resistance compared to Electron Beam Melted (EBM) titanium due to its refined microstructure and reduced internal defects. EBM titanium offers excellent ductility and consistent mechanical behavior but generally shows lower yield strength than VAR titanium. The choice between VAR and EBM titanium depends on specific application requirements where VAR is preferred for high-performance aerospace components needing maximum strength, while EBM suits complex geometries requiring moderate mechanical properties.

Industrial Applications: VAR vs EBM Titanium

Vacuum Arc Remelted (VAR) titanium offers superior control over chemical composition and inclusion removal, making it ideal for aerospace components requiring high strength and fatigue resistance. Electron Beam Melted (EBM) titanium provides enhanced uniformity and reduced segregation, benefiting medical implants and complex, precision-engineered parts. VAR titanium excels in large-scale production of structural aerospace elements, while EBM titanium is preferred for custom, intricate geometries in biomedical and aerospace applications.

Cost and Efficiency Analysis

Vacuum Arc Remelted (VAR) titanium typically incurs higher production costs due to slower melting rates and increased electrode consumption compared to Electron Beam Melted (EBM) titanium, which offers faster processing and better energy efficiency. EBM titanium also achieves superior material uniformity and reduced contamination, resulting in lower post-processing expenses and improved yield. Cost-benefit analysis reveals EBM as the more efficient option in large-scale or high-precision applications, despite its higher initial equipment investment.

Choosing the Right Melting Process for Specific Titanium Applications

Vacuum Arc Remelted (VAR) titanium offers superior control over chemical composition and is ideal for aerospace components requiring high purity and reduced inclusions. Electron Beam Melted (EBM) titanium provides excellent homogeneity and is favored for complex geometries and additive manufacturing in medical implants. Selecting the melting process depends on application-specific factors such as mechanical properties, microstructural consistency, and final component complexity.

Vacuum Arc Remelted Titanium vs Electron Beam Melted Titanium Infographic

materialdif.com

materialdif.com