Titanium carbide coating offers superior hardness and wear resistance compared to nitride coating, making it ideal for high-friction applications. While nitride coatings provide excellent corrosion resistance and lower friction, titanium carbide excels in extending tool life under extreme conditions. Choosing titanium carbide coating enhances durability and performance for demanding environments where surface toughness is critical.

Table of Comparison

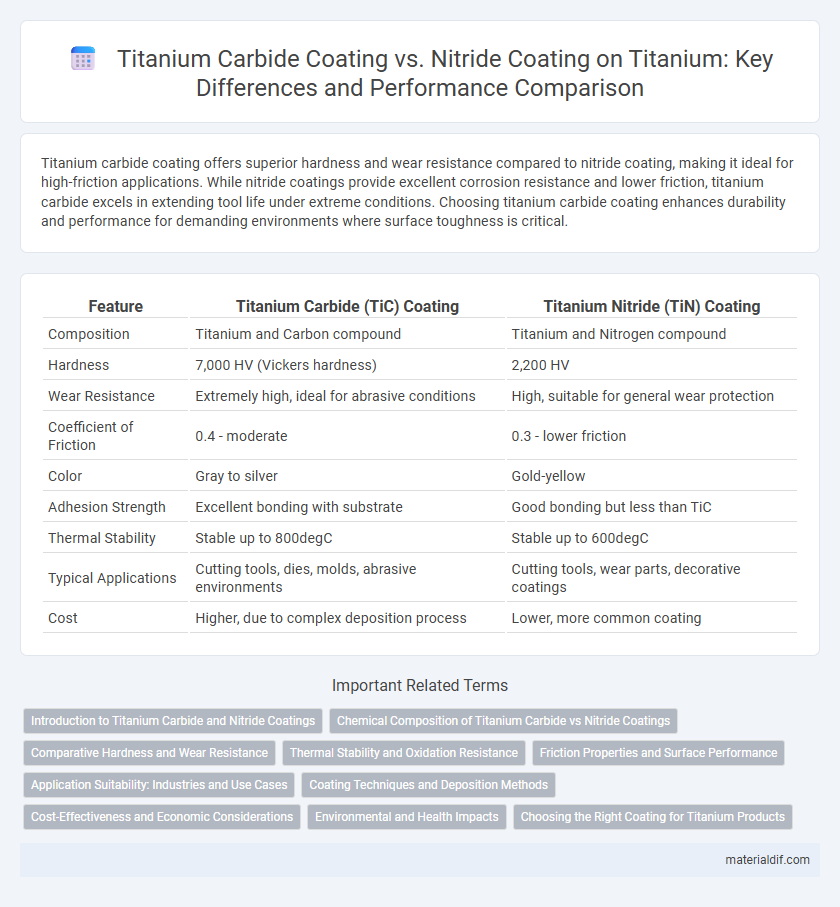

| Feature | Titanium Carbide (TiC) Coating | Titanium Nitride (TiN) Coating |

|---|---|---|

| Composition | Titanium and Carbon compound | Titanium and Nitrogen compound |

| Hardness | 7,000 HV (Vickers hardness) | 2,200 HV |

| Wear Resistance | Extremely high, ideal for abrasive conditions | High, suitable for general wear protection |

| Coefficient of Friction | 0.4 - moderate | 0.3 - lower friction |

| Color | Gray to silver | Gold-yellow |

| Adhesion Strength | Excellent bonding with substrate | Good bonding but less than TiC |

| Thermal Stability | Stable up to 800degC | Stable up to 600degC |

| Typical Applications | Cutting tools, dies, molds, abrasive environments | Cutting tools, wear parts, decorative coatings |

| Cost | Higher, due to complex deposition process | Lower, more common coating |

Introduction to Titanium Carbide and Nitride Coatings

Titanium Carbide coatings exhibit exceptional hardness and wear resistance, making them ideal for cutting tools and industrial applications requiring extreme durability. Titanium Nitride coatings offer superior corrosion resistance and a low coefficient of friction, which enhances tool life and performance in high-speed machining. Both coatings improve substrate protection but differ in chemical composition, affecting their specific industrial uses.

Chemical Composition of Titanium Carbide vs Nitride Coatings

Titanium Carbide (TiC) coatings primarily consist of a titanium and carbon compound, characterized by a hard, refractory ceramic structure with a high melting point and excellent wear resistance. In contrast, Titanium Nitride (TiN) coatings are composed of titanium and nitrogen, offering a distinctly different chemical composition that imparts superior corrosion resistance and a lower coefficient of friction. The presence of carbon in TiC provides enhanced hardness, whereas nitrogen in TiN contributes to improved oxidation stability and a striking golden appearance.

Comparative Hardness and Wear Resistance

Titanium carbide coating exhibits superior hardness, typically ranging from 2800 to 3200 HV, compared to titanium nitride coating, which generally measures around 1800 to 2100 HV. The higher hardness of titanium carbide results in enhanced wear resistance, making it ideal for applications involving abrasive conditions and high friction. In contrast, titanium nitride offers better oxidation resistance but falls short in extreme wear environments due to its comparatively lower hardness.

Thermal Stability and Oxidation Resistance

Titanium Carbide coating exhibits superior thermal stability withstanding temperatures up to 2900degC, making it ideal for high-temperature applications, whereas Titanium Nitride coating typically endures up to 800degC. In terms of oxidation resistance, Titanium Carbide forms a dense, stable oxide layer that significantly reduces oxidation at elevated temperatures, while Titanium Nitride generally offers moderate oxidation resistance due to its lower thermal tolerance. These differences make Titanium Carbide coatings preferable for extreme thermal environments requiring enhanced durability and minimal degradation.

Friction Properties and Surface Performance

Titanium carbide (TiC) coatings exhibit superior wear resistance and lower friction coefficients compared to titanium nitride (TiN) coatings, resulting in enhanced surface durability under high-stress conditions. TiC coatings offer increased hardness and excellent thermal stability, which improves cutting tool efficiency and lifespan by reducing frictional heat and adhesion. In contrast, TiN coatings provide good corrosion resistance and moderate friction reduction but generally fall short of TiC in terms of surface performance and mechanical robustness in abrasive environments.

Application Suitability: Industries and Use Cases

Titanium carbide coating excels in high-wear environments such as cutting tools, molds, and aerospace components due to its exceptional hardness and abrasion resistance. Titanium nitride coating is preferred in applications requiring oxidation resistance and low friction, making it ideal for medical devices, decorative finishes, and automotive parts. Industrial sectors like manufacturing, biomedical, and aerospace leverage these coatings based on specific mechanical and environmental performance requirements.

Coating Techniques and Deposition Methods

Titanium carbide coatings are primarily deposited using chemical vapor deposition (CVD) and physical vapor deposition (PVD) techniques, offering high hardness and wear resistance ideal for cutting tools and abrasive environments. In contrast, titanium nitride coatings are mostly applied via PVD methods such as sputtering and arc deposition, ensuring excellent adhesion, corrosion resistance, and a characteristic gold appearance. Both coating techniques utilize vacuum environments to control microstructure and thickness, but titanium carbide requires higher temperatures during CVD, influencing substrate compatibility and coating performance.

Cost-Effectiveness and Economic Considerations

Titanium carbide coating offers superior hardness and wear resistance at a relatively moderate cost, making it cost-effective for heavy-duty industrial applications. In contrast, titanium nitride coating, while providing excellent corrosion resistance and reducing friction, generally incurs lower initial expenses, suitable for less aggressive environments. Economic considerations favor titanium carbide when extended tool life and performance reduce replacement frequency, whereas titanium nitride is optimal for budget-conscious projects with moderate durability needs.

Environmental and Health Impacts

Titanium carbide coating exhibits superior resistance to wear and corrosion, reducing the frequency of recoating and minimizing hazardous waste generation compared to titanium nitride coating. Titanium nitride coatings may release reactive nitrogen compounds during processing, posing potential respiratory hazards, whereas titanium carbide coatings primarily involve carbon-based compounds with lower toxicity profiles. Both coatings require proper industrial ventilation and handling protocols, but titanium carbide's environmental impact is generally lower due to its longer durability and reduced need for frequent application.

Choosing the Right Coating for Titanium Products

Titanium carbide coating offers superior hardness and wear resistance, making it ideal for high-friction applications requiring extended tool life and durability. Nitride coatings, such as titanium nitride, provide excellent corrosion resistance and a lower coefficient of friction, suitable for parts exposed to harsh environments or requiring precise lubrication control. Selecting the right coating for titanium products depends on balancing the need for abrasion resistance, corrosion protection, and operational conditions specific to the application.

Titanium Carbide Coating vs Nitride Coating Infographic

materialdif.com

materialdif.com