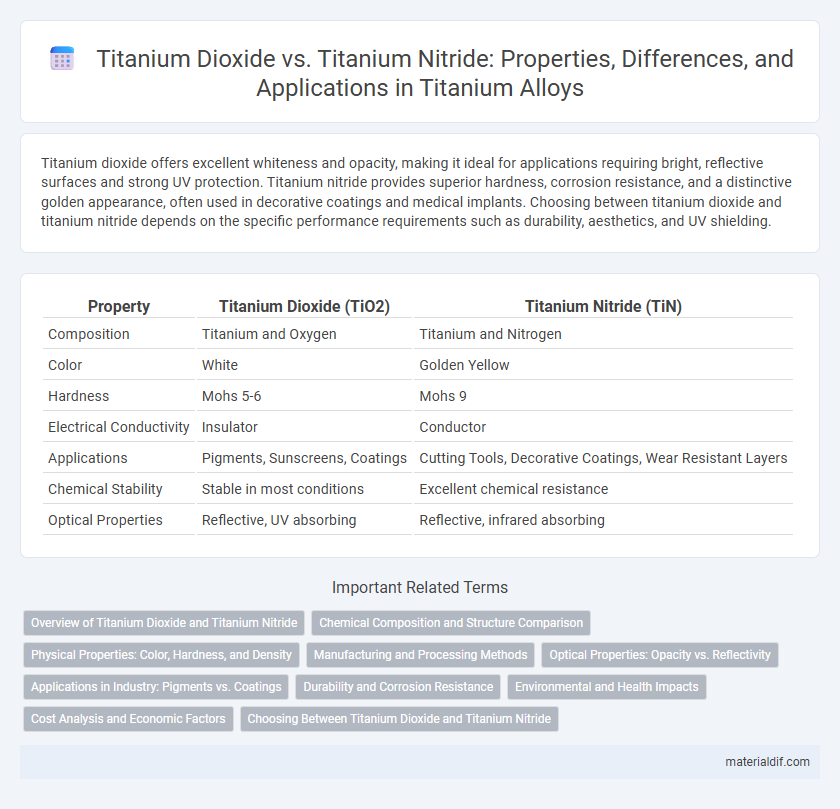

Titanium dioxide offers excellent whiteness and opacity, making it ideal for applications requiring bright, reflective surfaces and strong UV protection. Titanium nitride provides superior hardness, corrosion resistance, and a distinctive golden appearance, often used in decorative coatings and medical implants. Choosing between titanium dioxide and titanium nitride depends on the specific performance requirements such as durability, aesthetics, and UV shielding.

Table of Comparison

| Property | Titanium Dioxide (TiO2) | Titanium Nitride (TiN) |

|---|---|---|

| Composition | Titanium and Oxygen | Titanium and Nitrogen |

| Color | White | Golden Yellow |

| Hardness | Mohs 5-6 | Mohs 9 |

| Electrical Conductivity | Insulator | Conductor |

| Applications | Pigments, Sunscreens, Coatings | Cutting Tools, Decorative Coatings, Wear Resistant Layers |

| Chemical Stability | Stable in most conditions | Excellent chemical resistance |

| Optical Properties | Reflective, UV absorbing | Reflective, infrared absorbing |

Overview of Titanium Dioxide and Titanium Nitride

Titanium dioxide (TiO2) is a widely used white pigment known for its high refractive index, excellent UV resistance, and strong opacity, making it essential in paints, coatings, and sunscreens. Titanium nitride (TiN) features a gold-like appearance, exceptional hardness, and high thermal stability, commonly applied as a protective coating in cutting tools and medical devices. Both compounds leverage titanium's robust chemical properties but differ significantly in structure, color, and industrial applications.

Chemical Composition and Structure Comparison

Titanium dioxide (TiO2) is a white, crystalline oxide made of one titanium atom bonded to two oxygen atoms, exhibiting a tetragonal crystal structure primarily in the rutile or anatase phases. In contrast, titanium nitride (TiN) consists of titanium and nitrogen in a 1:1 ratio, forming a cubic face-centered structure known for its high hardness and metallic luster. The differing chemical compositions result in TiO2 functioning as an insulating photocatalyst, while TiN serves as a conductive, wear-resistant coating in industrial applications.

Physical Properties: Color, Hardness, and Density

Titanium Dioxide exhibits a white color with a hardness of 6 on the Mohs scale and a density of approximately 4.26 g/cm3, making it ideal for pigments and coatings. Titanium Nitride displays a characteristic gold color, a significantly higher hardness around 9 on the Mohs scale, and a density near 5.22 g/cm3, which contributes to its use in protective coatings and cutting tools. The stark differences in color, hardness, and density between these compounds determine their distinct industrial applications.

Manufacturing and Processing Methods

Titanium dioxide (TiO2) is primarily produced through the sulfate or chloride process involving the oxidation of titanium-containing ores, followed by purification and calcination to achieve high-purity pigment-grade powder. Titanium nitride (TiN) is typically manufactured using physical vapor deposition (PVD) or chemical vapor deposition (CVD) techniques, where titanium is vaporized in a nitrogen atmosphere to form hard, thin coatings on substrates. The distinct processing methods reflect their divergent applications, with TiO2 focusing on bulk pigment production and TiN emphasizing surface engineering and wear resistance.

Optical Properties: Opacity vs. Reflectivity

Titanium Dioxide exhibits high opacity due to its strong light-scattering properties, making it ideal for pigments and coatings that require excellent hiding power. In contrast, Titanium Nitride displays remarkable reflectivity with a golden metallic sheen, often used in decorative coatings and optical devices to enhance reflectance and durability. The choice between these compounds depends on whether opacity or reflectivity is required for specific optical applications.

Applications in Industry: Pigments vs. Coatings

Titanium dioxide is predominantly used as a white pigment in paints, plastics, paper, and cosmetics due to its high refractive index and brightness, enhancing opacity and durability. Titanium nitride, characterized by its metallic gold appearance, serves primarily as a hard coating for cutting tools, medical devices, and decorative finishes, offering exceptional wear resistance and corrosion protection. Industrial applications leverage titanium dioxide for color and coverage efficiency, while titanium nitride excels in surface modification to improve tool lifespan and aesthetic qualities.

Durability and Corrosion Resistance

Titanium Dioxide offers excellent corrosion resistance due to its stable oxide layer, making it suitable for protective coatings in harsh environments. Titanium Nitride, known for its superior hardness and wear resistance, enhances durability significantly but may require additional treatments to improve corrosion resistance in aggressive conditions. Both materials provide valuable benefits; Titanium Dioxide excels in chemical stability, while Titanium Nitride is optimal for applications demanding extreme surface durability.

Environmental and Health Impacts

Titanium dioxide (TiO2) is widely used as a white pigment and is generally considered safe, but concerns exist about its nanoparticle form potentially causing respiratory issues upon inhalation. Titanium nitride (TiN), known for its hardness and corrosion resistance, poses fewer health risks due to lower reactivity and lower likelihood of airborne exposure during use. Environmentally, titanium dioxide production has a higher carbon footprint and can contribute to water contamination, while titanium nitride's manufacturing involves less environmental toxicity and reduced chemical waste.

Cost Analysis and Economic Factors

Titanium dioxide offers a cost-effective solution with lower raw material expenses and simpler manufacturing processes compared to titanium nitride, which demands more complex synthesis techniques resulting in higher production costs. Economic factors favor titanium dioxide in bulk applications like paints and coatings due to its affordability and abundance. Titanium nitride, despite its higher cost, delivers superior hardness and corrosion resistance, justifying its price in specialized industrial uses such as cutting tools and protective coatings.

Choosing Between Titanium Dioxide and Titanium Nitride

Choosing between titanium dioxide and titanium nitride depends on their distinct properties and applications. Titanium dioxide offers superior UV protection and is widely used as a white pigment in paints and cosmetics due to its high refractive index and brightness. Titanium nitride, characterized by its hardness and golden color, is preferred for coating cutting tools and medical devices, delivering enhanced wear resistance and biocompatibility.

Titanium Dioxide vs Titanium Nitride Infographic

materialdif.com

materialdif.com