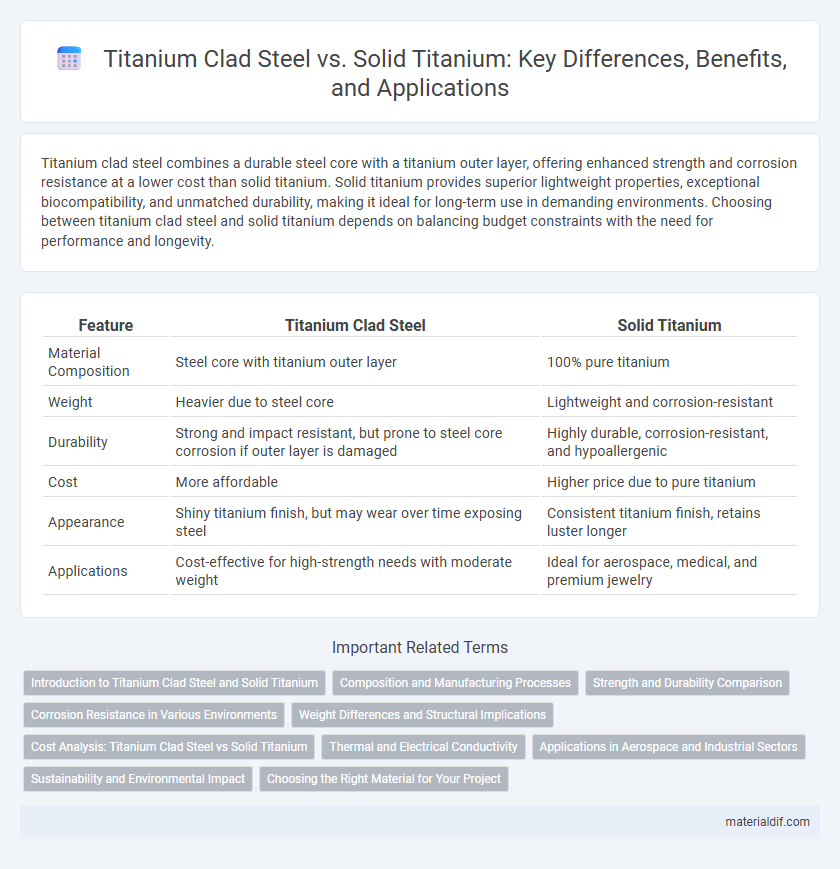

Titanium clad steel combines a durable steel core with a titanium outer layer, offering enhanced strength and corrosion resistance at a lower cost than solid titanium. Solid titanium provides superior lightweight properties, exceptional biocompatibility, and unmatched durability, making it ideal for long-term use in demanding environments. Choosing between titanium clad steel and solid titanium depends on balancing budget constraints with the need for performance and longevity.

Table of Comparison

| Feature | Titanium Clad Steel | Solid Titanium |

|---|---|---|

| Material Composition | Steel core with titanium outer layer | 100% pure titanium |

| Weight | Heavier due to steel core | Lightweight and corrosion-resistant |

| Durability | Strong and impact resistant, but prone to steel core corrosion if outer layer is damaged | Highly durable, corrosion-resistant, and hypoallergenic |

| Cost | More affordable | Higher price due to pure titanium |

| Appearance | Shiny titanium finish, but may wear over time exposing steel | Consistent titanium finish, retains luster longer |

| Applications | Cost-effective for high-strength needs with moderate weight | Ideal for aerospace, medical, and premium jewelry |

Introduction to Titanium Clad Steel and Solid Titanium

Titanium clad steel combines a core of high-strength steel with an outer layer of titanium, offering enhanced corrosion resistance and reduced weight compared to solid steel. Solid titanium is a lightweight, corrosion-resistant metal known for its high strength-to-weight ratio and excellent durability in extreme environments. Both materials are widely used in aerospace, medical devices, and chemical processing, where strength, weight, and corrosion resistance are critical factors.

Composition and Manufacturing Processes

Titanium clad steel consists of a steel core bonded with a titanium layer through processes such as explosive bonding or roll bonding, combining steel's strength with titanium's corrosion resistance. Solid titanium is composed entirely of titanium or titanium alloys, produced via melting and casting processes followed by extensive forging or rolling to achieve desired mechanical properties. The manufacturing complexity of titanium clad steel allows cost efficiency and tailored performance, whereas solid titanium offers superior purity and corrosion resistance due to its homogeneous composition.

Strength and Durability Comparison

Titanium clad steel combines the superior strength and toughness of steel with the corrosion resistance and lightweight properties of titanium, offering enhanced durability for structural applications. Solid titanium, while lighter and highly corrosion-resistant, generally has lower tensile strength compared to titanium clad steel, making it less suitable for high-stress environments. In terms of longevity, titanium clad steel provides a balanced performance by resisting wear and maintaining structural integrity under heavy loads better than solid titanium alone.

Corrosion Resistance in Various Environments

Titanium clad steel combines the strength and cost-effectiveness of steel with the excellent corrosion resistance of titanium, making it highly durable in marine, chemical, and industrial environments. Solid titanium offers superior corrosion resistance in extreme environments due to its pure composition, resisting oxidation, chlorides, and acidic conditions more effectively than titanium clad steel. Both materials provide excellent protection against corrosion, but solid titanium ensures longer lifespan and reliability in highly aggressive or corrosive atmospheres.

Weight Differences and Structural Implications

Titanium clad steel combines a lightweight titanium outer layer with a strong steel core, resulting in a material that offers reduced weight compared to solid titanium while maintaining higher strength and stiffness. Solid titanium is inherently lighter than steel but heavier than the composite clad steel due to pure titanium's density of approximately 4.5 g/cm3 versus steel's 7.85 g/cm3, influencing applications requiring specific weight-to-strength ratios. The structural implications include enhanced corrosion resistance and fatigue life in titanium clad steel, while solid titanium provides consistent performance under high-stress environments without laminate interface concerns.

Cost Analysis: Titanium Clad Steel vs Solid Titanium

Titanium clad steel offers a cost-effective alternative to solid titanium by combining the corrosion resistance and strength of titanium with the affordability of steel. Solid titanium, while more expensive due to its higher raw material cost and production complexity, provides superior durability and lightweight properties. The cost analysis reveals titanium clad steel reduces overall expenses by up to 40% compared to solid titanium without significantly compromising performance in many industrial applications.

Thermal and Electrical Conductivity

Titanium clad steel combines the lightweight, corrosion-resistant properties of titanium with the strength and cost-effectiveness of steel, but its thermal and electrical conductivity is significantly influenced by the steel core, resulting in lower conductivity compared to solid titanium. Solid titanium exhibits superior thermal conductivity, approximately 21.9 W/m*K, and electrical conductivity around 2.38% IACS (International Annealed Copper Standard), making it more efficient in heat dissipation and electrical applications. The composite nature of titanium clad steel often reduces these conductive properties due to the differing conductivity values of steel, which typically has lower thermal and electrical conductivity than titanium.

Applications in Aerospace and Industrial Sectors

Titanium clad steel offers a cost-effective solution with high strength and corrosion resistance, making it ideal for aerospace components requiring durability under extreme conditions. Solid titanium provides superior weight-to-strength ratio and exceptional resistance to high temperatures, preferred in critical aerospace parts such as jet engines and airframes. In industrial sectors, titanium clad steel is commonly used for chemical processing equipment, while solid titanium is favored for high-performance applications demanding maximum corrosion resistance and structural integrity.

Sustainability and Environmental Impact

Titanium clad steel offers a sustainable alternative by combining the high strength and recyclability of steel with the corrosion resistance of titanium, reducing the need for frequent replacements and lowering resource consumption. Solid titanium, while highly durable and corrosion-resistant, requires significant energy-intensive extraction and processing, contributing to a larger carbon footprint. Using titanium clad steel minimizes environmental impact by optimizing material usage and promoting recycling within construction and manufacturing industries.

Choosing the Right Material for Your Project

Titanium clad steel combines a durable steel core with a corrosion-resistant titanium exterior, offering a cost-effective solution for projects requiring strength and lightweight properties. Solid titanium provides superior corrosion resistance, biocompatibility, and a higher strength-to-weight ratio, making it ideal for high-performance applications in aerospace or medical industries. Selecting the right material depends on project-specific needs such as budget, environmental conditions, and mechanical requirements.

Titanium Clad Steel vs Solid Titanium Infographic

materialdif.com

materialdif.com