AMS 4902 titanium offers superior corrosion resistance and enhanced strength, making it ideal for marine and chemical processing applications. AMS 4911 titanium provides a balanced combination of weldability and ductility, often preferred in aerospace components requiring complex fabrication. Choosing between AMS 4902 and AMS 4911 depends on the specific demands of strength, corrosion resistance, and manufacturing processes.

Table of Comparison

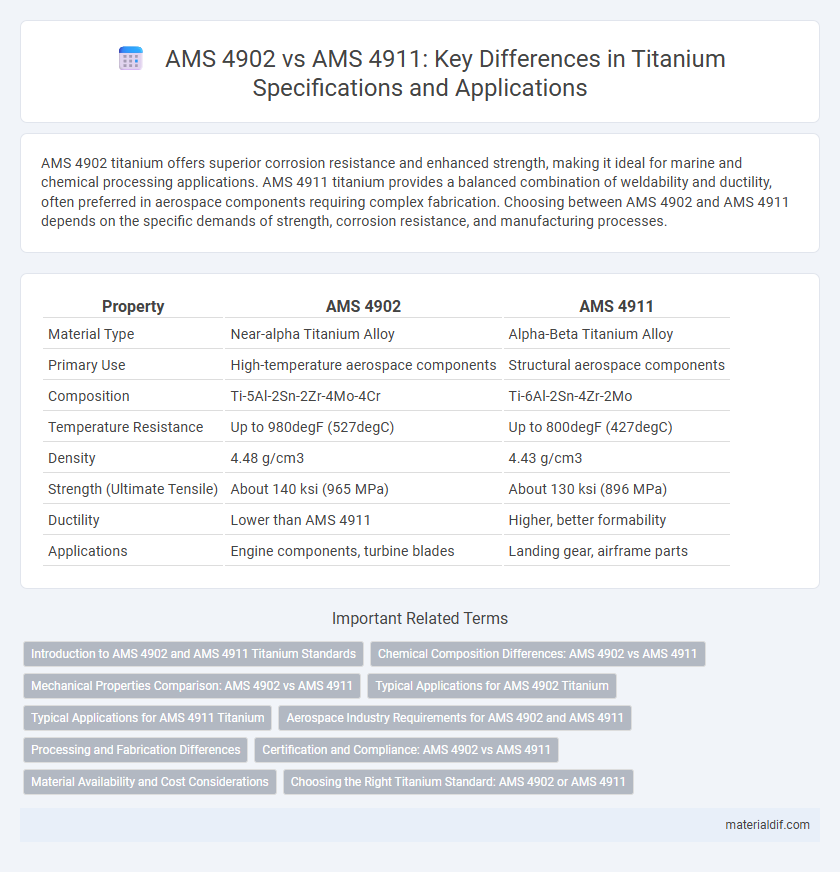

| Property | AMS 4902 | AMS 4911 |

|---|---|---|

| Material Type | Near-alpha Titanium Alloy | Alpha-Beta Titanium Alloy |

| Primary Use | High-temperature aerospace components | Structural aerospace components |

| Composition | Ti-5Al-2Sn-2Zr-4Mo-4Cr | Ti-6Al-2Sn-4Zr-2Mo |

| Temperature Resistance | Up to 980degF (527degC) | Up to 800degF (427degC) |

| Density | 4.48 g/cm3 | 4.43 g/cm3 |

| Strength (Ultimate Tensile) | About 140 ksi (965 MPa) | About 130 ksi (896 MPa) |

| Ductility | Lower than AMS 4911 | Higher, better formability |

| Applications | Engine components, turbine blades | Landing gear, airframe parts |

Introduction to AMS 4902 and AMS 4911 Titanium Standards

AMS 4902 and AMS 4911 are key aerospace material specifications for titanium alloys, with AMS 4902 covering annealed or solution-treated titanium alloy sheet including grades such as Ti-6Al-4V, primarily used for high-strength, corrosion-resistant applications. AMS 4911 focuses on titanium alloy plate and sheet in the annealed condition, designed for aerospace structures requiring enhanced toughness and formability. Both standards ensure critical mechanical properties and chemical compositions aligned with stringent aerospace industry requirements for titanium components.

Chemical Composition Differences: AMS 4902 vs AMS 4911

AMS 4902 titanium alloy contains higher aluminum and vanadium content, with approximately 6% Al and 4% V, enhancing strength and corrosion resistance. AMS 4911 features lower aluminum content, around 4.5% Al, and increased molybdenum, which improves creep resistance and high-temperature stability. These chemical composition differences significantly impact the mechanical properties and application suitability of each alloy.

Mechanical Properties Comparison: AMS 4902 vs AMS 4911

AMS 4902 titanium alloy exhibits higher tensile strength and improved fatigue resistance compared to AMS 4911, which offers superior toughness and ductility. AMS 4902's yield strength typically surpasses 140 ksi, while AMS 4911 maintains excellent elongation with values around 15-20%. The differences in mechanical properties make AMS 4902 ideal for high-stress aerospace components, whereas AMS 4911 suits applications requiring enhanced formability and impact resistance.

Typical Applications for AMS 4902 Titanium

AMS 4902 titanium is commonly used in aerospace components such as aircraft engine parts, landing gear, and structural airframe elements due to its excellent balance of strength, corrosion resistance, and fatigue performance. Unlike AMS 4911, which is often selected for medical implants and industrial equipment requiring high corrosion resistance and formability, AMS 4902 excels in high-stress, temperature-critical environments. Typical applications leverage AMS 4902 titanium's ability to maintain mechanical integrity under dynamic loading and elevated temperatures.

Typical Applications for AMS 4911 Titanium

AMS 4911 titanium is primarily used in aerospace components requiring superior strength, corrosion resistance, and weldability, such as aircraft structural parts, engine components, and fasteners. Its enhanced mechanical properties and toughness make it ideal for high-performance applications in jet engines and airframes. Compared to AMS 4902, AMS 4911 offers better fatigue resistance, which is crucial for critical aerospace applications.

Aerospace Industry Requirements for AMS 4902 and AMS 4911

AMS 4902 specifies titanium alloy Ti-6Al-4V annealed, meeting aerospace industry requirements for high strength, corrosion resistance, and excellent weldability, ideal for aircraft structural components and engine parts. AMS 4911 covers solution-treated and aged Ti-6Al-4V, offering superior mechanical properties suitable for critical aerospace applications requiring enhanced fatigue resistance and damage tolerance. Both standards align with stringent aerospace quality controls but differ in heat treatment, impacting their performance in aerospace manufacturing and maintenance.

Processing and Fabrication Differences

AMS 4902 titanium alloy is primarily processed through powder metallurgy, offering superior strength and fatigue resistance after hot isostatic pressing, while AMS 4911 is conventionally wrought and focuses on improved formability with balanced strength. Fabrication of AMS 4902 requires precise control of temperature during sintering and HIP to achieve optimal microstructure, whereas AMS 4911 allows for more flexible rolling and forging operations due to its thermomechanical properties. These processing distinctions result in AMS 4902 being preferred for high-performance aerospace components, while AMS 4911 suits applications needing complex shapes with moderate mechanical demands.

Certification and Compliance: AMS 4902 vs AMS 4911

AMS 4902 titanium alloy provides stringent certification requirements tailored for aerospace components demanding high strength and fatigue resistance, ensuring compliance with major industry standards like ASTM and ASME. AMS 4911 specifies testing protocols and material traceability focused on corrosion resistance and weldability, emphasizing compliance with aerospace quality systems such as NADCAP and ISO 9001. Comparing AMS 4902 and AMS 4911 reveals differences in certification scope, with AMS 4902 prioritizing mechanical property validation and AMS 4911 focusing on chemical composition control and microstructural verification.

Material Availability and Cost Considerations

AMS 4902 titanium alloy offers higher availability due to its widespread use in aerospace applications, making it more cost-effective for large-scale production. AMS 4911, while providing superior corrosion resistance and strength, is less commonly stocked, resulting in higher material costs and longer lead times. Choosing AMS 4902 often optimizes project budgets without compromising essential performance characteristics.

Choosing the Right Titanium Standard: AMS 4902 or AMS 4911

AMS 4902 titanium offers superior corrosion resistance and strength for aerospace components, making it ideal for high-stress structural applications. AMS 4911, with its enhanced toughness and formability, suits complex-shaped parts requiring excellent fatigue performance. Selecting the right standard depends on balancing mechanical properties and fabrication requirements specific to the intended titanium component.

AMS 4902 vs AMS 4911 Infographic

materialdif.com

materialdif.com