Cold-worked titanium undergoes deformation at room temperature, enhancing its strength and hardness through strain hardening while retaining superior corrosion resistance, making it ideal for precision applications. Hot-worked titanium is shaped at elevated temperatures, improving its ductility and reducing residual stresses, which benefits forming complex shapes and large components. Choosing between cold-worked and hot-worked titanium depends on the balance needed between mechanical strength, flexibility, and manufacturing requirements.

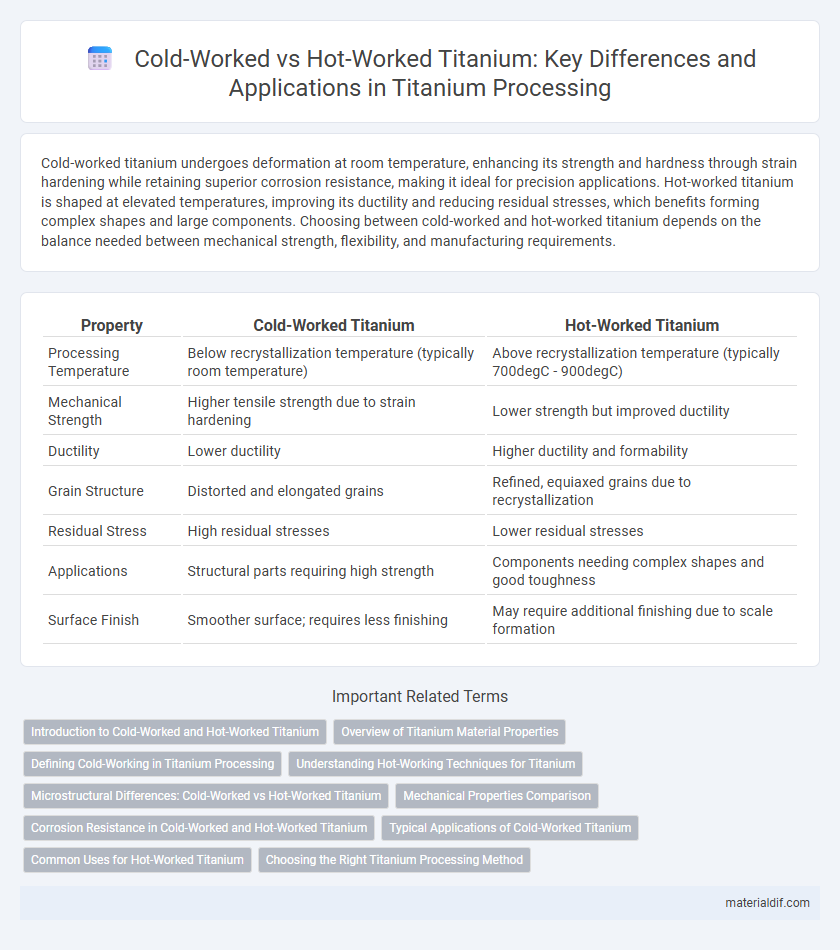

Table of Comparison

| Property | Cold-Worked Titanium | Hot-Worked Titanium |

|---|---|---|

| Processing Temperature | Below recrystallization temperature (typically room temperature) | Above recrystallization temperature (typically 700degC - 900degC) |

| Mechanical Strength | Higher tensile strength due to strain hardening | Lower strength but improved ductility |

| Ductility | Lower ductility | Higher ductility and formability |

| Grain Structure | Distorted and elongated grains | Refined, equiaxed grains due to recrystallization |

| Residual Stress | High residual stresses | Lower residual stresses |

| Applications | Structural parts requiring high strength | Components needing complex shapes and good toughness |

| Surface Finish | Smoother surface; requires less finishing | May require additional finishing due to scale formation |

Introduction to Cold-Worked and Hot-Worked Titanium

Cold-worked titanium undergoes plastic deformation at or near room temperature, enhancing its strength and hardness through strain hardening while maintaining excellent corrosion resistance. Hot-worked titanium is processed at elevated temperatures above its recrystallization point, resulting in improved ductility and refined grain structure, which is essential for complex shaping and forming applications. Both methods are crucial in aerospace and medical industries, optimizing titanium's mechanical properties for specific performance requirements.

Overview of Titanium Material Properties

Cold-worked titanium exhibits increased strength and hardness due to strain hardening, but this process can reduce ductility and toughness compared to hot-worked titanium. Hot-worked titanium undergoes processing at elevated temperatures, which enhances its microstructural uniformity, improving ductility and fracture resistance while maintaining good strength. The choice between cold-worked and hot-worked titanium depends on the balance needed between mechanical strength, formability, and fatigue resistance for specific aerospace or medical applications.

Defining Cold-Working in Titanium Processing

Cold-working titanium involves deforming the metal at temperatures below its recrystallization point, enhancing its strength and hardness through strain hardening without altering its microstructure. This process increases dislocation density, leading to improved mechanical properties such as tensile strength and fatigue resistance. Unlike hot-working, cold-working maintains dimensional accuracy and surface finish, making it ideal for precision titanium components in aerospace and medical applications.

Understanding Hot-Working Techniques for Titanium

Hot-working techniques for titanium involve deforming the metal at elevated temperatures, typically between 700degC and 950degC, to enhance its ductility and reduce internal stresses. This process refines the grain structure, improving toughness and allowing for complex shapes that are not achievable through cold-working. Understanding the thermal stability and oxidation resistance of titanium during hot-working is crucial for optimizing mechanical properties and ensuring structural integrity.

Microstructural Differences: Cold-Worked vs Hot-Worked Titanium

Cold-worked titanium exhibits a refined microstructure characterized by elongated grains and increased dislocation density, enhancing its strength and hardness through strain hardening. In contrast, hot-worked titanium undergoes recrystallization during processing, resulting in equiaxed grains with reduced dislocation density that improve ductility and toughness. These microstructural differences directly influence the mechanical properties and applications of titanium alloys in aerospace and biomedical fields.

Mechanical Properties Comparison

Cold-worked titanium exhibits higher yield strength and hardness due to strain hardening but has reduced ductility compared to hot-worked titanium. Hot-worked titanium offers improved toughness and better machinability as the thermal process refines grain structure and relieves internal stresses. The choice between cold and hot working depends on balancing tensile strength requirements with desired flexibility and impact resistance in applications.

Corrosion Resistance in Cold-Worked and Hot-Worked Titanium

Cold-worked titanium exhibits enhanced corrosion resistance due to strain hardening and the formation of a stable, protective oxide layer, making it highly effective in aggressive chemical environments. Hot-worked titanium, while more ductile and easier to shape, may have a slightly reduced corrosion resistance because elevated temperatures can alter the microstructure and oxide layer integrity. Both processing methods maintain titanium's inherent resistance to corrosion, but cold working often results in improved durability in chloride-containing environments and acidic conditions.

Typical Applications of Cold-Worked Titanium

Cold-worked titanium is predominantly used in aerospace components, medical devices, and chemical processing equipment due to its enhanced strength and improved fatigue resistance. Its applications include aircraft structural parts, surgical implants, and heat exchangers, where precision and durability are critical. The cold-working process refines the microstructure, resulting in superior mechanical properties ideal for high-performance and corrosion-resistant environments.

Common Uses for Hot-Worked Titanium

Hot-worked titanium is widely used in aerospace components, chemical processing equipment, and automotive parts due to its enhanced ductility and improved mechanical properties. The hot working process refines the microstructure, resulting in superior strength and corrosion resistance, making it ideal for high-performance structural applications. Industrial sectors also utilize hot-worked titanium for heat exchangers, pressure vessels, and marine hardware where durability under extreme conditions is critical.

Choosing the Right Titanium Processing Method

Cold-worked titanium offers enhanced strength and improved surface finish due to strain hardening, making it ideal for applications demanding high fatigue resistance and precise tolerances. Hot-worked titanium provides superior ductility and is suited for complex shapes and large components, benefiting from recrystallization that relieves internal stresses. Selecting the right processing method depends on balancing the need for mechanical properties, component complexity, and final application requirements.

Cold-Worked Titanium vs Hot-Worked Titanium Infographic

materialdif.com

materialdif.com