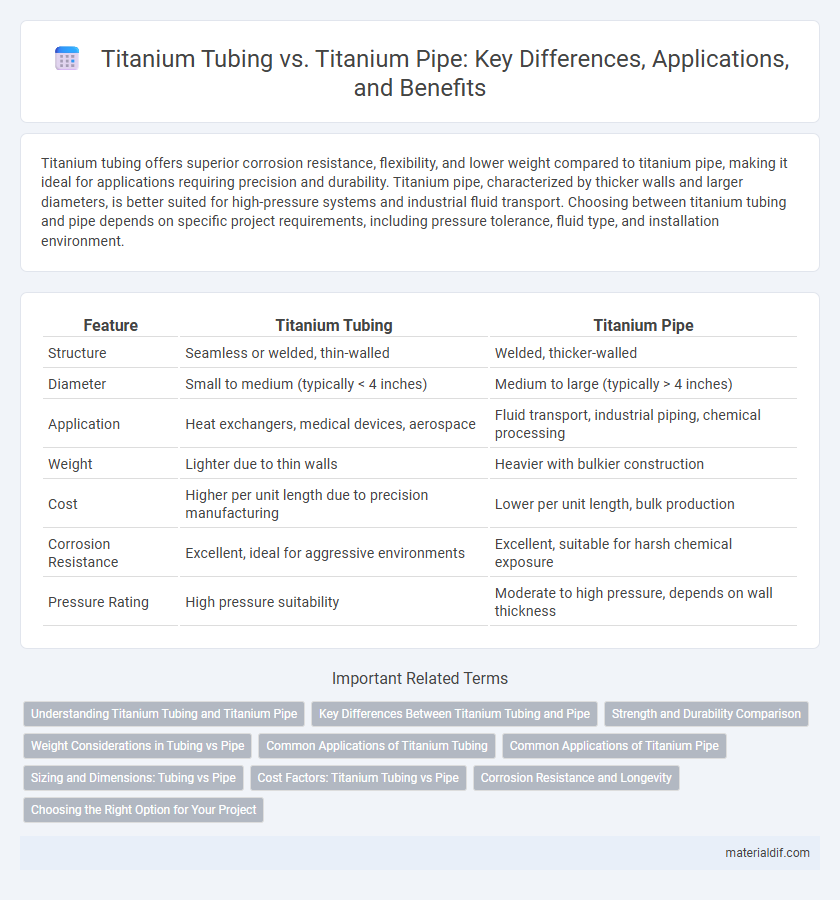

Titanium tubing offers superior corrosion resistance, flexibility, and lower weight compared to titanium pipe, making it ideal for applications requiring precision and durability. Titanium pipe, characterized by thicker walls and larger diameters, is better suited for high-pressure systems and industrial fluid transport. Choosing between titanium tubing and pipe depends on specific project requirements, including pressure tolerance, fluid type, and installation environment.

Table of Comparison

| Feature | Titanium Tubing | Titanium Pipe |

|---|---|---|

| Structure | Seamless or welded, thin-walled | Welded, thicker-walled |

| Diameter | Small to medium (typically < 4 inches) | Medium to large (typically > 4 inches) |

| Application | Heat exchangers, medical devices, aerospace | Fluid transport, industrial piping, chemical processing |

| Weight | Lighter due to thin walls | Heavier with bulkier construction |

| Cost | Higher per unit length due to precision manufacturing | Lower per unit length, bulk production |

| Corrosion Resistance | Excellent, ideal for aggressive environments | Excellent, suitable for harsh chemical exposure |

| Pressure Rating | High pressure suitability | Moderate to high pressure, depends on wall thickness |

Understanding Titanium Tubing and Titanium Pipe

Titanium tubing is characterized by its precise dimensions, thinner walls, and is commonly used in applications requiring lightweight and corrosion-resistant materials, such as aerospace and medical devices. Titanium pipe, on the other hand, features thicker walls and larger diameters, making it suitable for high-pressure industrial systems like chemical processing and oil refineries. Both titanium tubing and pipe offer exceptional strength-to-weight ratios and superior corrosion resistance, but selection depends on specific pressure, dimensional, and application requirements.

Key Differences Between Titanium Tubing and Pipe

Titanium tubing features precise dimensions and uniform wall thickness, making it ideal for high-performance applications such as aerospace and medical devices, whereas titanium pipe typically has thicker walls and larger diameters suited for fluid transport and structural uses. Titanium tubing offers superior corrosion resistance and lightweight properties combined with flexibility in design, whereas pipes prioritize strength and durability in high-pressure environments. The manufacturing methods differ: tubing is often seamless or welded with tight tolerances, while pipes can be heavier and less precise, reflecting their distinct industrial purposes.

Strength and Durability Comparison

Titanium tubing offers superior strength-to-weight ratio compared to titanium pipe, making it ideal for applications requiring lightweight yet robust materials. The seamless construction of titanium tubing enhances durability by reducing potential weak points, whereas titanium pipe may have welded seams that could affect long-term performance. Both materials exhibit excellent corrosion resistance, but tubing's enhanced fatigue resistance makes it more suitable for high-stress environments.

Weight Considerations in Tubing vs Pipe

Titanium tubing generally offers a lighter weight option compared to titanium pipe due to its thinner walls and precise manufacturing tolerances, making it ideal for applications demanding both strength and weight efficiency. The reduced weight of titanium tubing enhances performance in aerospace, medical, and automotive industries where minimizing mass is critical without sacrificing corrosion resistance or mechanical integrity. In contrast, titanium pipe, often used for structural or fluid transport purposes, typically features thicker walls that increase weight but provide greater durability and pressure-handling capabilities.

Common Applications of Titanium Tubing

Titanium tubing is widely used in aerospace, medical devices, and chemical processing due to its superior strength-to-weight ratio, corrosion resistance, and biocompatibility. Unlike titanium pipe, which is primarily employed for fluid transport in industrial systems, titanium tubing finds applications in structural components, heat exchangers, and medical implants where precision and durability are critical. The tubing's seamless construction and flexibility enable its use in aircraft hydraulic systems, surgical instruments, and marine environments.

Common Applications of Titanium Pipe

Titanium pipe is widely used in aerospace, chemical processing, and marine industries due to its exceptional corrosion resistance and high strength-to-weight ratio. Its seamless construction and durability make it ideal for transporting aggressive fluids and high-pressure steam. In contrast, titanium tubing is often preferred in applications requiring precision and flexibility, such as medical devices and heat exchangers.

Sizing and Dimensions: Tubing vs Pipe

Titanium tubing typically features tighter dimensional tolerances and thinner walls compared to titanium pipe, making it ideal for precision applications requiring exact sizing. Titanium pipes are generally larger in diameter with thicker walls, designed to handle higher pressure and structural demands. The sizing of titanium tubing often follows outside diameter (OD) and wall thickness, while titanium pipe measurements include nominal pipe size (NPS) and schedule number, reflecting differences in their manufacturing standards and uses.

Cost Factors: Titanium Tubing vs Pipe

Titanium tubing generally costs more than titanium pipe due to its tighter manufacturing tolerances and more complex production processes, which ensure precise dimensions and superior strength for specialized applications. Titanium pipe is typically less expensive as it is produced in larger dimensions with standard thickness, making it suitable for fluid transport in industries like chemical processing or aerospace at a lower cost. Cost differences also arise from customization requirements, with titanium tubing often demanding additional finishing and quality certifications that increase overall expenses.

Corrosion Resistance and Longevity

Titanium tubing offers superior corrosion resistance due to its seamless construction, reducing potential sites for corrosion compared to welded titanium pipe. The high strength-to-weight ratio of titanium tubing enhances longevity in aggressive environments such as marine and chemical processing industries. Both forms resist chloride-induced stress corrosion cracking, but tubing's uniform wall thickness provides more consistent durability over extended service life.

Choosing the Right Option for Your Project

Titanium tubing offers precision and uniformity, making it ideal for applications requiring tight tolerances, corrosion resistance, and lightweight strength, such as aerospace and medical devices. Titanium pipe suits larger-scale projects involving fluid transport or structural support, delivering durability and resistance to harsh environments with greater diameter options. Assessing project requirements like dimensional accuracy, pressure ratings, and installation environment ensures the best choice between titanium tubing and pipe for optimal performance and cost-efficiency.

Titanium Tubing vs Titanium Pipe Infographic

materialdif.com

materialdif.com