Electropolished titanium offers a smooth, corrosion-resistant surface by removing microscopic peaks and impurities, enhancing biocompatibility and durability compared to mechanically polished titanium, which relies on abrasive methods that may leave fine scratches and residues. The electropolishing process creates a uniform oxide layer that improves resistance to wear and bacterial adhesion, making it ideal for medical implants and high-precision applications. Mechanically polished titanium, while effective for general aesthetics, lacks the superior surface finish and long-term performance benefits found in electropolished counterparts.

Table of Comparison

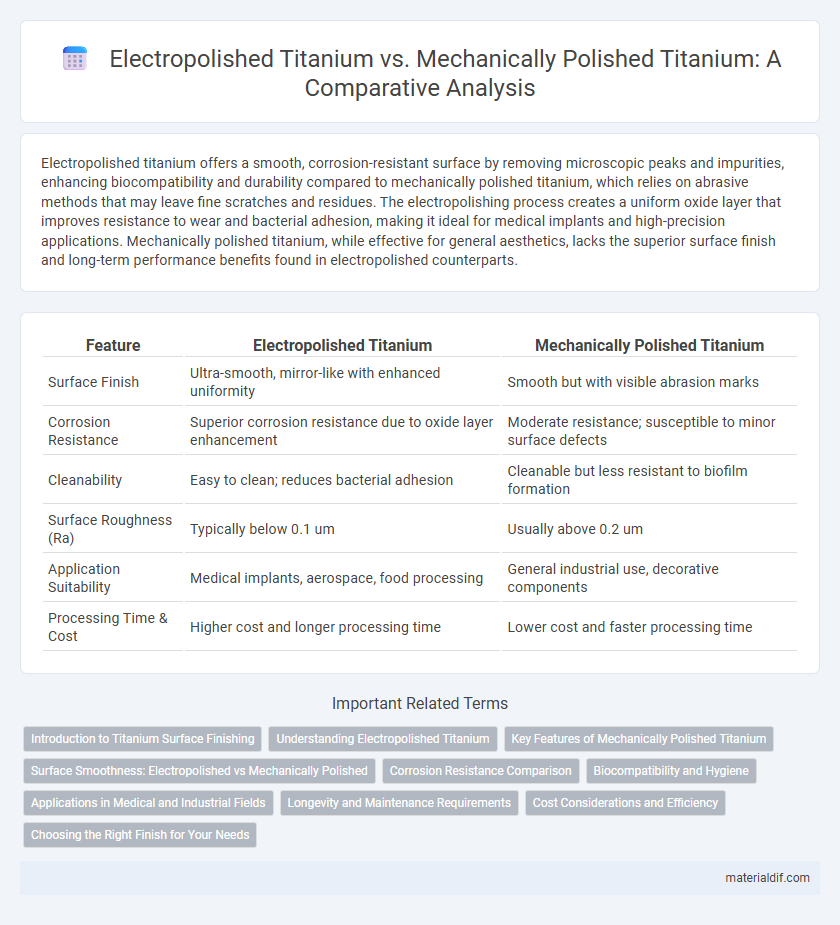

| Feature | Electropolished Titanium | Mechanically Polished Titanium |

|---|---|---|

| Surface Finish | Ultra-smooth, mirror-like with enhanced uniformity | Smooth but with visible abrasion marks |

| Corrosion Resistance | Superior corrosion resistance due to oxide layer enhancement | Moderate resistance; susceptible to minor surface defects |

| Cleanability | Easy to clean; reduces bacterial adhesion | Cleanable but less resistant to biofilm formation |

| Surface Roughness (Ra) | Typically below 0.1 um | Usually above 0.2 um |

| Application Suitability | Medical implants, aerospace, food processing | General industrial use, decorative components |

| Processing Time & Cost | Higher cost and longer processing time | Lower cost and faster processing time |

Introduction to Titanium Surface Finishing

Electropolished titanium offers a smooth, contamination-free surface by selectively removing material at a microscopic level, enhancing corrosion resistance and biocompatibility compared to mechanically polished titanium, which relies on abrasive techniques that can leave micro-scratches and embedded particles. The electropolishing process improves surface cleanliness and passivation, making it ideal for medical implants, aerospace, and chemical processing industries. Mechanically polished titanium, while cost-effective, often requires additional treatments to achieve similar levels of cleanliness and corrosion resistance.

Understanding Electropolished Titanium

Electropolished titanium offers a superior surface finish by removing microscopic peaks and valleys through an electrochemical process, resulting in enhanced corrosion resistance and biocompatibility compared to mechanically polished titanium. This process creates a smoother, cleaner surface that reduces bacterial adhesion and improves the material's resistance to oxidation and chemical exposure. Electropolishing is widely utilized in medical, aerospace, and chemical industries where titanium's durability and purity are critical.

Key Features of Mechanically Polished Titanium

Mechanically polished titanium features a smooth, reflective surface achieved through abrasive processes, enhancing its aesthetic appeal and cleanability. This method improves surface hardness and wear resistance, making it suitable for applications requiring durability. Unlike electropolishing, mechanical polishing does not alter the titanium's chemical composition, preserving its inherent corrosion resistance.

Surface Smoothness: Electropolished vs Mechanically Polished

Electropolished titanium achieves superior surface smoothness by selectively dissolving microscopic peaks, resulting in a uniform, mirror-like finish with reduced surface roughness compared to mechanically polished titanium. Mechanical polishing relies on abrasive action, which can leave fine scratches and uneven textures, reducing overall smoothness and corrosion resistance. Electropolishing enhances not only the aesthetic appeal but also the material's resistance to contamination and bacterial adhesion due to its smoother surface profile.

Corrosion Resistance Comparison

Electropolished titanium exhibits superior corrosion resistance compared to mechanically polished titanium due to the removal of surface contaminants and the formation of a uniform, passive oxide layer. The electropolishing process enhances the metal's surface smoothness at a microscopic level, reducing sites for corrosion initiation and improving resistance against pitting and crevice corrosion. Mechanically polished titanium, while smoother than raw surfaces, retains micro-scratches and embedded impurities that can compromise corrosion resistance over time.

Biocompatibility and Hygiene

Electropolished titanium offers superior biocompatibility and hygiene compared to mechanically polished titanium due to its smoother surface that minimizes bacterial adhesion and biofilm formation. The electropolishing process removes microscopic surface imperfections, enhancing corrosion resistance and reducing the risk of metal ion release, which is critical for medical implants and biomedical applications. Mechanically polished titanium, while smoother than untreated surfaces, retains micro-scratches that can harbor contaminants and compromise long-term biocompatibility and cleanliness.

Applications in Medical and Industrial Fields

Electropolished titanium offers superior surface smoothness and enhanced corrosion resistance compared to mechanically polished titanium, making it ideal for medical implants and surgical instruments where biocompatibility and sterility are critical. In industrial applications, electropolished titanium components provide improved fatigue strength and contamination resistance, benefiting aerospace, chemical processing, and semiconductor manufacturing. Mechanically polished titanium, while cost-effective, may retain micro-abrasions that reduce hygiene and corrosion performance, limiting its use in high-precision medical and industrial environments.

Longevity and Maintenance Requirements

Electropolished titanium offers superior corrosion resistance and a smoother surface compared to mechanically polished titanium, resulting in enhanced longevity and reduced susceptibility to surface contaminants. The electropolishing process removes surface imperfections and micro-roughness, minimizing bacterial adhesion and making maintenance easier with less frequent cleaning required. Mechanically polished titanium, while visually appealing, retains microscopic scratches that can harbor debris and accelerate corrosion, increasing maintenance demands and potentially shortening the material's lifespan.

Cost Considerations and Efficiency

Electropolished titanium typically incurs higher upfront costs due to specialized equipment and chemical processing but offers superior surface smoothness that reduces contamination risks and maintenance expenses over time. Mechanically polished titanium demands less initial investment and simpler equipment, yet it may require more frequent re-polishing due to surface micro-scratches and potential corrosion sites. Efficiency gains in electropolishing arise from enhanced corrosion resistance and longer lifespan, outweighing the higher initial cost for critical applications in aerospace, medical, and chemical industries.

Choosing the Right Finish for Your Needs

Electropolished titanium offers superior corrosion resistance and a smoother surface finish compared to mechanically polished titanium, making it ideal for medical implants and aerospace components. Mechanically polished titanium provides a lower-cost option with adequate aesthetic appeal and durability for less demanding environments such as automotive or architectural applications. Selecting the right finish depends on factors like exposure to harsh conditions, required surface purity, and budget constraints.

Electropolished Titanium vs Mechanically Polished Titanium Infographic

materialdif.com

materialdif.com