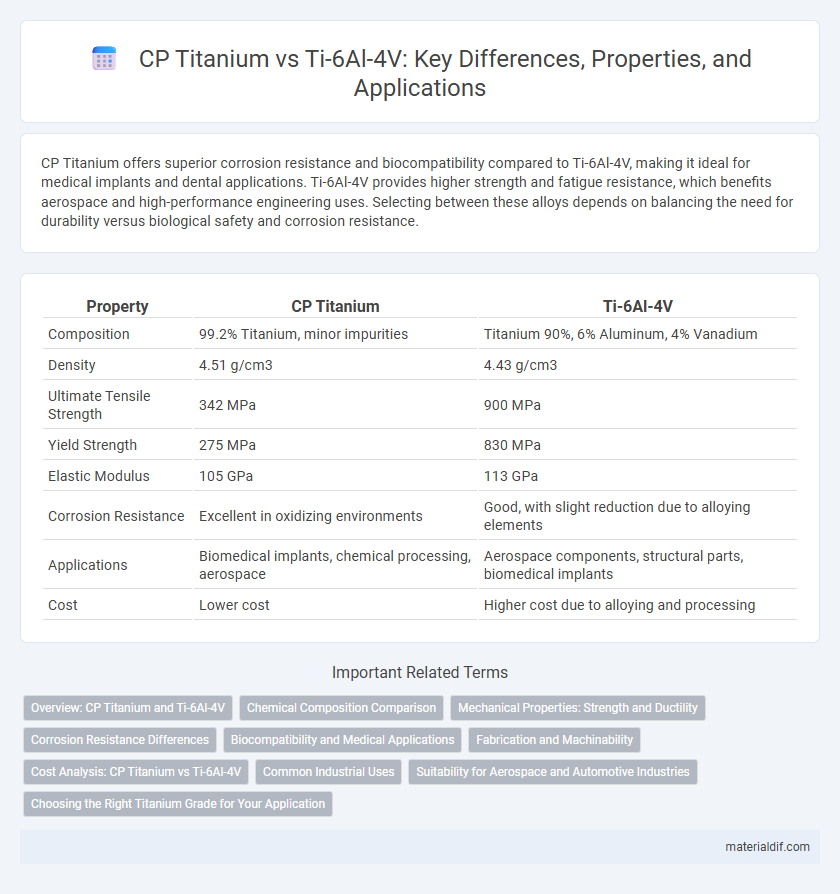

CP Titanium offers superior corrosion resistance and biocompatibility compared to Ti-6Al-4V, making it ideal for medical implants and dental applications. Ti-6Al-4V provides higher strength and fatigue resistance, which benefits aerospace and high-performance engineering uses. Selecting between these alloys depends on balancing the need for durability versus biological safety and corrosion resistance.

Table of Comparison

| Property | CP Titanium | Ti-6Al-4V |

|---|---|---|

| Composition | 99.2% Titanium, minor impurities | Titanium 90%, 6% Aluminum, 4% Vanadium |

| Density | 4.51 g/cm3 | 4.43 g/cm3 |

| Ultimate Tensile Strength | 342 MPa | 900 MPa |

| Yield Strength | 275 MPa | 830 MPa |

| Elastic Modulus | 105 GPa | 113 GPa |

| Corrosion Resistance | Excellent in oxidizing environments | Good, with slight reduction due to alloying elements |

| Applications | Biomedical implants, chemical processing, aerospace | Aerospace components, structural parts, biomedical implants |

| Cost | Lower cost | Higher cost due to alloying and processing |

Overview: CP Titanium and Ti-6Al-4V

CP Titanium, or Commercially Pure Titanium, is known for its excellent corrosion resistance, high strength-to-weight ratio, and biocompatibility, making it ideal for medical implants and aerospace components. Ti-6Al-4V, an alpha-beta titanium alloy containing 6% aluminum and 4% vanadium, offers superior mechanical properties, including higher tensile strength and fatigue resistance, used extensively in aerospace, automotive, and military applications. Both materials provide distinct advantages in performance and application versatility based on strength requirements and environmental exposure.

Chemical Composition Comparison

CP Titanium primarily consists of nearly pure titanium with minimal impurities such as iron and oxygen, typically less than 0.3% combined. Ti-6Al-4V features an alloy composition with approximately 6% aluminum and 4% vanadium, enhancing strength and corrosion resistance compared to CP Titanium. The presence of aluminum and vanadium in Ti-6Al-4V significantly alters its mechanical properties and chemical stability, making it suitable for aerospace and biomedical applications.

Mechanical Properties: Strength and Ductility

CP Titanium offers excellent corrosion resistance and high ductility but has lower tensile strength compared to Ti-6Al-4V, making it ideal for applications requiring flexibility. Ti-6Al-4V alloy exhibits superior mechanical strength and hardness, with tensile strength ranging from 900 to 1100 MPa, while maintaining good ductility for structural performance. This combination of strength and moderate ductility makes Ti-6Al-4V preferred for aerospace and biomedical applications demanding high load-bearing capacity.

Corrosion Resistance Differences

CP Titanium exhibits superior corrosion resistance compared to Ti-6Al-4V due to its commercially pure composition, which forms a stable and protective oxide layer in aggressive environments. Ti-6Al-4V, an alpha-beta alloy containing aluminum and vanadium, is more prone to localized corrosion such as pitting and crevice corrosion in chloride-rich or acidic conditions. This difference makes CP Titanium the preferred choice for marine, chemical processing, and biomedical applications where corrosion resistance is critical.

Biocompatibility and Medical Applications

CP Titanium exhibits excellent biocompatibility, making it highly suitable for implants and dental applications due to its low allergenic potential and corrosion resistance. Ti-6Al-4V alloy, while also biocompatible, offers superior mechanical strength and fatigue resistance, commonly used in load-bearing orthopedic implants and surgical instruments. Both materials are favored in medical applications, with CP Titanium preferred for soft tissue integration and Ti-6Al-4V selected for high-stress, durable implant requirements.

Fabrication and Machinability

CP Titanium exhibits superior corrosion resistance and is easier to machine due to its lower strength and simpler microstructure, making it ideal for applications requiring intricate fabrication. Ti-6Al-4V, an alpha-beta alloy, offers higher strength and better fatigue resistance but presents more challenges during machining, requiring advanced tooling and slower feed rates. Both materials require specialized machining environments to manage heat and tool wear, with CP Titanium favored for cost-effective fabrication and Ti-6Al-4V preferred for high-performance structural components.

Cost Analysis: CP Titanium vs Ti-6Al-4V

CP Titanium typically costs less than Ti-6Al-4V due to its simpler alloy composition and lower processing requirements. Ti-6Al-4V, a titanium alloy with aluminum and vanadium, offers superior strength and corrosion resistance but involves higher manufacturing and material expenses. The cost difference significantly impacts industries such as aerospace and medical implants, where performance demands justify the premium price of Ti-6Al-4V.

Common Industrial Uses

CP Titanium is widely used in aerospace components, chemical processing, and medical implants due to its excellent corrosion resistance and biocompatibility. Ti-6Al-4V, the most common titanium alloy, is favored in high-strength applications such as aerospace airframes, automotive parts, and marine engineering because of its superior mechanical properties. Both materials are essential in manufacturing but differ in strength and corrosion resistance, influencing their industrial applications.

Suitability for Aerospace and Automotive Industries

CP Titanium offers excellent corrosion resistance and biocompatibility, making it ideal for aerospace components exposed to harsh environments, while Ti-6Al-4V provides superior strength and fatigue resistance, crucial for high-performance aerospace structures and automotive parts. Ti-6Al-4V's alloy composition enhances mechanical properties, enabling lightweight yet durable components, preferred in aerospace frames and high-stress automotive applications. CP Titanium's lower strength limits its use in structural applications but suits non-load-bearing parts where corrosion resistance is paramount.

Choosing the Right Titanium Grade for Your Application

CP Titanium offers excellent corrosion resistance and biocompatibility, making it ideal for medical implants and chemical processing equipment. Ti-6Al-4V, an aluminum-vanadium alloy, provides superior strength and fatigue resistance, suited for aerospace, automotive, and high-performance engineering applications. Selecting the right titanium grade depends on specific requirements for strength, corrosion resistance, weight, and cost-efficiency in your intended use.

CP Titanium vs Ti-6Al-4V Infographic

materialdif.com

materialdif.com