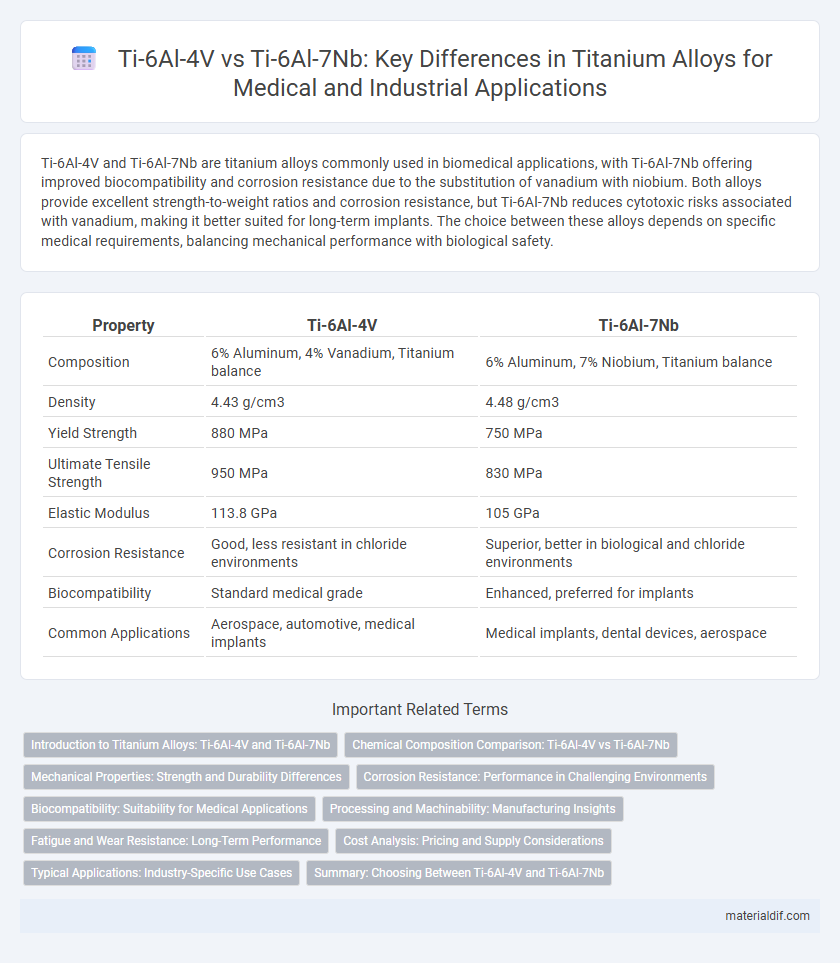

Ti-6Al-4V and Ti-6Al-7Nb are titanium alloys commonly used in biomedical applications, with Ti-6Al-7Nb offering improved biocompatibility and corrosion resistance due to the substitution of vanadium with niobium. Both alloys provide excellent strength-to-weight ratios and corrosion resistance, but Ti-6Al-7Nb reduces cytotoxic risks associated with vanadium, making it better suited for long-term implants. The choice between these alloys depends on specific medical requirements, balancing mechanical performance with biological safety.

Table of Comparison

| Property | Ti-6Al-4V | Ti-6Al-7Nb |

|---|---|---|

| Composition | 6% Aluminum, 4% Vanadium, Titanium balance | 6% Aluminum, 7% Niobium, Titanium balance |

| Density | 4.43 g/cm3 | 4.48 g/cm3 |

| Yield Strength | 880 MPa | 750 MPa |

| Ultimate Tensile Strength | 950 MPa | 830 MPa |

| Elastic Modulus | 113.8 GPa | 105 GPa |

| Corrosion Resistance | Good, less resistant in chloride environments | Superior, better in biological and chloride environments |

| Biocompatibility | Standard medical grade | Enhanced, preferred for implants |

| Common Applications | Aerospace, automotive, medical implants | Medical implants, dental devices, aerospace |

Introduction to Titanium Alloys: Ti-6Al-4V and Ti-6Al-7Nb

Ti-6Al-4V and Ti-6Al-7Nb are prominent titanium alloys widely used in aerospace, biomedical, and industrial applications due to their exceptional strength-to-weight ratio and corrosion resistance. Ti-6Al-4V, composed of 6% aluminum and 4% vanadium, offers excellent mechanical properties and weldability, making it the most commonly used titanium alloy. Ti-6Al-7Nb, which replaces vanadium with 7% niobium, enhances biocompatibility and reduces cytotoxicity, making it particularly suitable for medical implants and devices.

Chemical Composition Comparison: Ti-6Al-4V vs Ti-6Al-7Nb

Ti-6Al-4V alloy consists primarily of 90% titanium, 6% aluminum, and 4% vanadium, offering a balance of strength and corrosion resistance commonly used in aerospace applications. In contrast, Ti-6Al-7Nb substitutes vanadium with 7% niobium, enhancing biocompatibility and reducing allergenic responses for medical implants. This chemical variation between vanadium and niobium directly influences the alloys' mechanical properties and suitability for specific industrial or biomedical applications.

Mechanical Properties: Strength and Durability Differences

Ti-6Al-4V alloy exhibits higher tensile strength and superior fatigue resistance compared to Ti-6Al-7Nb, making it more suitable for high-stress structural applications. Ti-6Al-7Nb offers improved corrosion resistance and biocompatibility but generally has slightly lower ultimate tensile strength and fatigue life. The addition of niobium in Ti-6Al-7Nb enhances its durability in biomedical environments while maintaining adequate mechanical integrity.

Corrosion Resistance: Performance in Challenging Environments

Ti-6Al-7Nb exhibits superior corrosion resistance compared to Ti-6Al-4V, particularly in aggressive chloride environments due to the stabilizing effect of niobium on the passive oxide layer. This niobium-enhanced alloy demonstrates enhanced biocompatibility and reduced ion release, making it ideal for biomedical implants exposed to physiological fluids. Ti-6Al-4V, although widely used, is more susceptible to localized corrosion and titanium ion dissolution in harsh conditions, potentially affecting long-term durability.

Biocompatibility: Suitability for Medical Applications

Ti-6Al-7Nb exhibits enhanced biocompatibility compared to Ti-6Al-4V due to the substitution of vanadium with niobium, which reduces potential cytotoxicity and allergic reactions in medical implants. Niobium contributes to improved corrosion resistance and osseointegration, making Ti-6Al-7Nb more suitable for long-term implantation in orthopedic and dental applications. Both alloys maintain excellent strength-to-weight ratios, but Ti-6Al-7Nb's superior biological performance enhances patient safety and implant longevity.

Processing and Machinability: Manufacturing Insights

Ti-6Al-4V exhibits superior machinability due to lower alloying content and well-established processing parameters, making it ideal for high-volume manufacturing with precise control. Ti-6Al-7Nb, containing niobium instead of vanadium, offers enhanced corrosion resistance but poses increased machining challenges, often requiring specialized tooling and slower cutting speeds. Advanced additive manufacturing techniques benefit both alloys, yet Ti-6Al-4V's widespread acceptance supports more cost-effective and optimized production workflows.

Fatigue and Wear Resistance: Long-Term Performance

Ti-6Al-4V exhibits high fatigue strength and wear resistance, making it ideal for aerospace and medical implants under cyclic loading conditions. Ti-6Al-7Nb offers improved biocompatibility with slightly enhanced wear resistance but generally shows comparable fatigue performance in long-term applications. Both alloys demonstrate excellent durability, yet Ti-6Al-4V remains preferred where maximum fatigue resistance is critical.

Cost Analysis: Pricing and Supply Considerations

Ti-6Al-4V titanium alloy generally commands lower prices due to its widespread production and established supply chains, making it the preferred choice for large-scale industrial applications. Ti-6Al-7Nb, often used in biomedical fields for its enhanced biocompatibility, tends to be more expensive because of limited suppliers and specialized manufacturing processes. The cost differential impacts procurement decisions, balancing performance requirements against budget constraints in aerospace, medical, and manufacturing sectors.

Typical Applications: Industry-Specific Use Cases

Ti-6Al-4V is widely used in aerospace components, medical implants, and high-performance automotive parts due to its exceptional strength-to-weight ratio and corrosion resistance. Ti-6Al-7Nb finds specific applications in biomedical implants, especially orthopedic and dental devices, where enhanced biocompatibility and reduced allergenic potential are critical. Both alloys serve critical roles in industries demanding high durability and biocompatibility but are chosen based on specific performance requirements and regulatory standards.

Summary: Choosing Between Ti-6Al-4V and Ti-6Al-7Nb

Ti-6Al-4V offers superior strength and fatigue resistance, making it ideal for aerospace and high-performance engineering applications, while Ti-6Al-7Nb provides enhanced biocompatibility and corrosion resistance, favored in medical implants and biomedical fields. The substitution of vanadium with niobium in Ti-6Al-7Nb reduces cytotoxic risks, improving long-term implantation safety. Selection depends on the critical parameters of mechanical performance versus biological compatibility within the intended application.

Ti-6Al-4V vs Ti-6Al-7Nb Infographic

materialdif.com

materialdif.com