Titanium billet offers enhanced mechanical properties and superior surface finish compared to titanium ingot, making it ideal for high-performance applications. While titanium ingots serve as the raw material for forging and shaping, billets provide a more refined and consistent microstructure that improves strength and corrosion resistance. Choosing titanium billet over ingot results in better precision and reliability for demanding industrial and aerospace components.

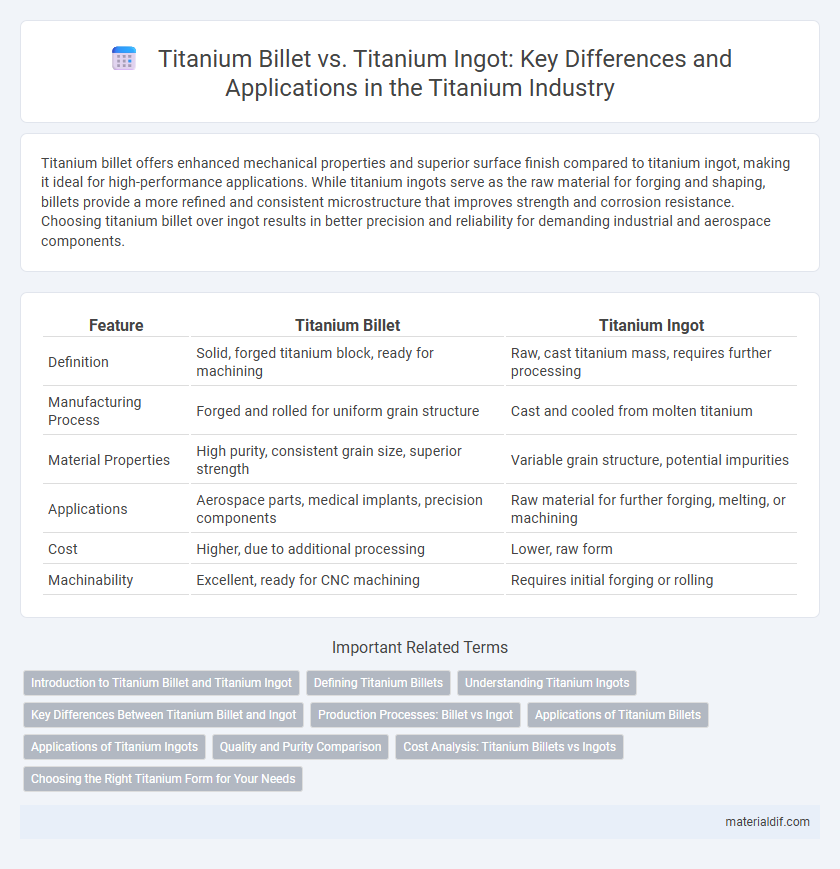

Table of Comparison

| Feature | Titanium Billet | Titanium Ingot |

|---|---|---|

| Definition | Solid, forged titanium block, ready for machining | Raw, cast titanium mass, requires further processing |

| Manufacturing Process | Forged and rolled for uniform grain structure | Cast and cooled from molten titanium |

| Material Properties | High purity, consistent grain size, superior strength | Variable grain structure, potential impurities |

| Applications | Aerospace parts, medical implants, precision components | Raw material for further forging, melting, or machining |

| Cost | Higher, due to additional processing | Lower, raw form |

| Machinability | Excellent, ready for CNC machining | Requires initial forging or rolling |

Introduction to Titanium Billet and Titanium Ingot

Titanium billet is a solid cylindrical or rectangular piece of titanium metal, produced through forging or extrusion processes, offering superior mechanical properties and uniform grain structure for high-performance applications. Titanium ingot is the initial cast form of titanium, created by melting and solidifying raw titanium material, serving as the primary feedstock for further processing into billets or other shapes. The billet's refined microstructure provides enhanced strength and machinability compared to the ingot, making it ideal for aerospace, medical, and automotive components.

Defining Titanium Billets

Titanium billets are semi-finished metal products formed by extruding or forging molten titanium into cylindrical or rectangular shapes, offering uniform grain structure and enhanced mechanical properties. Unlike titanium ingots, which are raw cast forms requiring extensive machining, billets provide higher material consistency and dimensional accuracy for aerospace and medical applications. Their improved density and reduced impurities make them ideal for precision components demanding superior strength and corrosion resistance.

Understanding Titanium Ingots

Titanium ingots are large, solid blocks of pure titanium formed through the melting and casting of titanium sponge or scrap, serving as the initial raw material for further processing into billets and other shapes. These ingots provide uniform composition and structural integrity, essential for high-performance applications in aerospace, medical implants, and automotive industries. Understanding the metallurgical properties and production methods of titanium ingots is crucial for optimizing downstream machining and achieving precise mechanical characteristics in finished titanium components.

Key Differences Between Titanium Billet and Ingot

Titanium billet is a solid, rectangular or square-shaped piece of titanium metal formed through forging or rolling processes, offering superior mechanical properties and uniformity compared to ingots. Titanium ingot is a larger, raw cast form of titanium metal created by solidifying molten titanium, often requiring further processing to achieve refined grain structure and desired mechanical strength. The key differences between titanium billet and ingot lie in their production methods, structural homogeneity, and suitability for high-performance applications.

Production Processes: Billet vs Ingot

Titanium billet is produced through a forging process where molten titanium is poured into molds and then subjected to controlled heating and mechanical deformation, enhancing its density and mechanical properties. In contrast, titanium ingot forms by casting molten titanium into large, rough blocks that cool and solidify naturally, requiring further processing to achieve desired material characteristics. The billet's refined microstructure from forging results in superior strength and uniformity compared to the relatively coarse grain structure of the ingot.

Applications of Titanium Billets

Titanium billets are widely used in aerospace, automotive, and medical industries due to their superior strength-to-weight ratio and excellent corrosion resistance. These billets serve as the raw material for precision machining of critical components such as aircraft structural parts, engine components, and orthopedic implants. Their uniform microstructure and high-quality surface finish make titanium billets ideal for high-performance and high-reliability applications.

Applications of Titanium Ingots

Titanium ingots are primarily used in aerospace, medical, and automotive industries due to their superior strength, corrosion resistance, and ability to withstand extreme temperatures. These ingots serve as the raw material for forging, rolling, and machining into high-performance components such as aircraft frames, surgical implants, and high-end automotive parts. Their versatility and excellent mechanical properties make titanium ingots essential for manufacturing critical, lightweight, and durable products.

Quality and Purity Comparison

Titanium billets exhibit higher quality and purity compared to titanium ingots due to their refined microstructure and reduced impurities from the secondary processing steps. The advanced forging and rolling techniques used in billet production ensure enhanced mechanical properties and consistent grain flow, resulting in superior strength and durability. In contrast, titanium ingots, formed during initial solidification, often contain more inclusions and heterogeneities, which can compromise material performance in critical applications.

Cost Analysis: Titanium Billets vs Ingots

Titanium billets generally offer a higher cost efficiency compared to titanium ingots due to their pre-forged, near-net shape form which reduces machining and material waste during manufacturing. In contrast, titanium ingots require extensive processing and machining, leading to increased labor costs, longer production times, and higher overall expenses. Evaluating the cost analysis, billets provide significant savings in production cycles and material utilization, making them more economically viable for high-precision aerospace and automotive applications.

Choosing the Right Titanium Form for Your Needs

Titanium billet offers superior mechanical properties and precise machining capabilities, ideal for aerospace and medical applications requiring high strength and fine detail. Titanium ingot, being a larger cast form, is suited for initial melting and large-scale forging processes where volume and cost-efficiency are prioritized. Selecting the right titanium form depends on the specific requirements for strength, surface finish, and production scale in your manufacturing process.

Titanium Billet vs Titanium Ingot Infographic

materialdif.com

materialdif.com