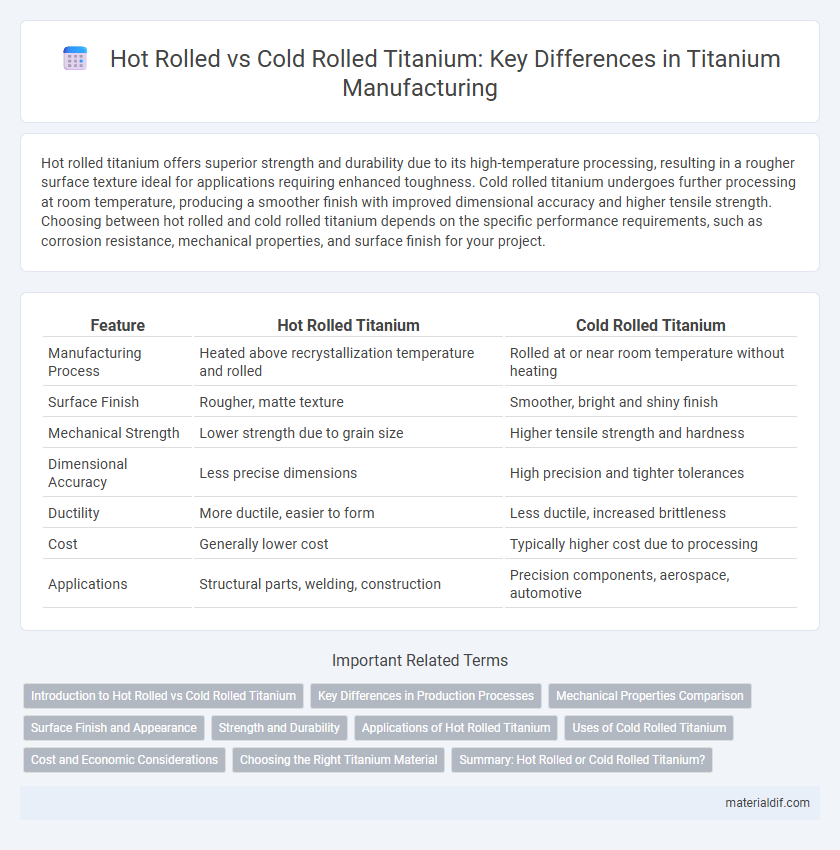

Hot rolled titanium offers superior strength and durability due to its high-temperature processing, resulting in a rougher surface texture ideal for applications requiring enhanced toughness. Cold rolled titanium undergoes further processing at room temperature, producing a smoother finish with improved dimensional accuracy and higher tensile strength. Choosing between hot rolled and cold rolled titanium depends on the specific performance requirements, such as corrosion resistance, mechanical properties, and surface finish for your project.

Table of Comparison

| Feature | Hot Rolled Titanium | Cold Rolled Titanium |

|---|---|---|

| Manufacturing Process | Heated above recrystallization temperature and rolled | Rolled at or near room temperature without heating |

| Surface Finish | Rougher, matte texture | Smoother, bright and shiny finish |

| Mechanical Strength | Lower strength due to grain size | Higher tensile strength and hardness |

| Dimensional Accuracy | Less precise dimensions | High precision and tighter tolerances |

| Ductility | More ductile, easier to form | Less ductile, increased brittleness |

| Cost | Generally lower cost | Typically higher cost due to processing |

| Applications | Structural parts, welding, construction | Precision components, aerospace, automotive |

Introduction to Hot Rolled vs Cold Rolled Titanium

Hot rolled titanium undergoes processing at high temperatures above its recrystallization point, enhancing its ductility and reducing internal stresses, which results in a coarser surface finish and less precise dimensions. Cold rolled titanium is processed at or near room temperature, improving strength, hardness, and surface finish while maintaining tighter tolerances due to work hardening effects. Understanding these differences is crucial for selecting the appropriate titanium form for applications requiring specific mechanical properties and surface qualities.

Key Differences in Production Processes

Hot rolled titanium undergoes processing at high temperatures above its recrystallization point, allowing the metal to be shaped easily with reduced stress and enhanced ductility. Cold rolled titanium is formed at or near room temperature, resulting in increased strength and improved surface finish due to strain hardening and tighter dimensional tolerances. The distinct production processes lead to differences in mechanical properties, surface characteristics, and potential applications for each type.

Mechanical Properties Comparison

Hot rolled titanium exhibits enhanced ductility and toughness due to its processing at elevated temperatures, resulting in a more uniform grain structure. Cold rolled titanium demonstrates superior tensile strength and hardness, achieved through strain hardening during deformation at room temperature. The choice between hot rolled and cold rolled titanium depends on application-specific mechanical requirements, with hot rolled favoring impact resistance and cold rolled excelling in strength and wear resistance.

Surface Finish and Appearance

Hot rolled titanium exhibits a rougher surface finish with visible scale and oxide layers, making it less suitable for applications requiring smooth aesthetics. Cold rolled titanium undergoes additional processing to enhance surface smoothness, resulting in a more refined, polished appearance ideal for decorative and precision components. The differences in surface texture significantly impact corrosion resistance and subsequent coating adhesion in industrial uses.

Strength and Durability

Hot rolled titanium exhibits superior strength due to its manufacturing process, which involves heating the metal above its recrystallization temperature, resulting in a more uniform grain structure and enhanced durability. Cold rolled titanium, while offering improved surface finish and dimensional accuracy, typically has slightly lower strength but increased hardness from strain hardening. The choice between hot rolled and cold rolled titanium ultimately depends on the specific application requirements for strength and toughness versus surface quality and precision.

Applications of Hot Rolled Titanium

Hot rolled titanium is widely used in aerospace and automotive industries due to its enhanced strength and durability at elevated temperatures. This form of titanium is ideal for structural components, shipbuilding, and heavy machinery where toughness and resistance to fatigue are critical. Its coarse surface texture also makes it preferable for applications requiring subsequent forging or machining.

Uses of Cold Rolled Titanium

Cold rolled titanium offers superior surface finish and tighter dimensional tolerances, making it ideal for aerospace components, medical devices, and precision engineering. Its enhanced strength and hardness from the cold rolling process contribute to applications requiring durability and corrosion resistance. Manufacturers prefer cold rolled titanium for high-performance parts in automotive, chemical processing, and consumer electronics industries.

Cost and Economic Considerations

Hot rolled titanium typically incurs lower production costs due to its simpler manufacturing process and higher throughput, making it economically favorable for large-scale applications. Cold rolled titanium, while more expensive because of the additional processing required to achieve tighter tolerances and superior surface finish, provides enhanced mechanical properties and dimensional accuracy that justify its cost in precision-demanding industries. Businesses evaluating titanium materials balance budget constraints with performance requirements, often choosing hot rolled variants for cost efficiency and cold rolled grades when quality and precision deliver greater long-term value.

Choosing the Right Titanium Material

Choosing the right titanium material depends on the application's strength and finish requirements, where hot rolled titanium offers enhanced toughness and structural integrity due to its high-temperature processing. Cold rolled titanium provides superior surface smoothness and tighter dimensional tolerances, ideal for precision components and aesthetic applications. Understanding the mechanical properties and finishing needs ensures optimal material performance in aerospace, medical, or industrial settings.

Summary: Hot Rolled or Cold Rolled Titanium?

Hot rolled titanium features a rougher surface finish and enhanced ductility due to processing at high temperatures, making it ideal for structural applications requiring toughness. Cold rolled titanium offers superior dimensional accuracy, smoother surface finish, and increased strength from strain hardening, preferred for precision components and aesthetic demands. Choosing between hot rolled or cold rolled titanium depends on balancing mechanical properties, surface quality, and cost for specific industrial uses.

Hot Rolled Titanium vs Cold Rolled Titanium Infographic

materialdif.com

materialdif.com