Anodized titanium offers enhanced corrosion resistance and a vibrant, customizable color finish compared to untreated titanium, which maintains its natural metallic appearance but is more prone to surface wear and oxidation. The anodization process creates a protective oxide layer that improves durability and reduces allergy risks in pet products. Untreated titanium remains lightweight and biocompatible, but anodized versions provide added aesthetic appeal and long-term performance for pets.

Table of Comparison

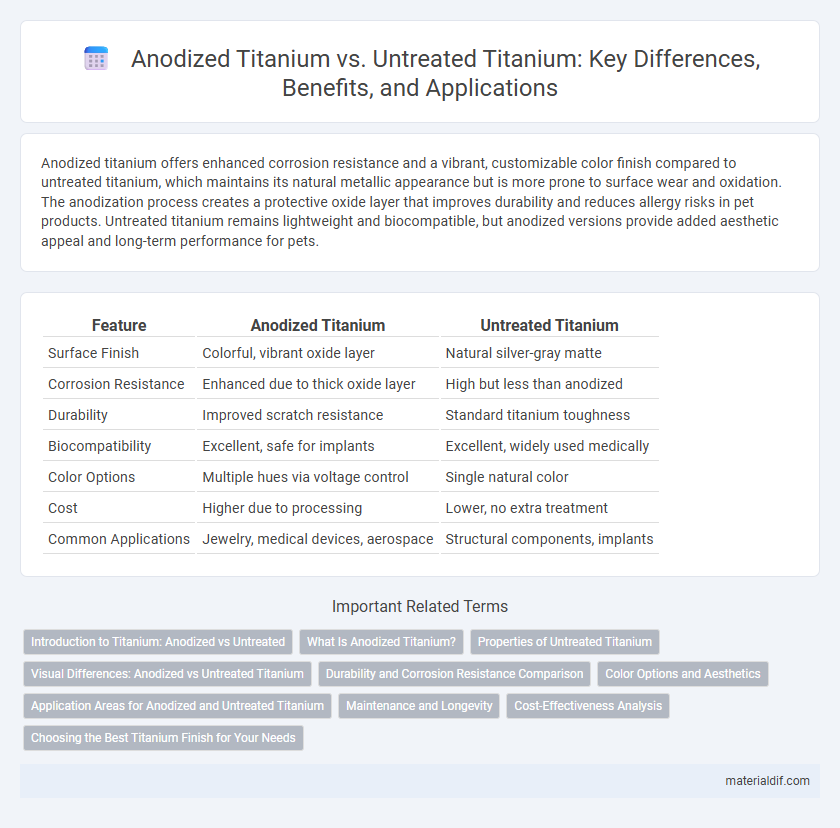

| Feature | Anodized Titanium | Untreated Titanium |

|---|---|---|

| Surface Finish | Colorful, vibrant oxide layer | Natural silver-gray matte |

| Corrosion Resistance | Enhanced due to thick oxide layer | High but less than anodized |

| Durability | Improved scratch resistance | Standard titanium toughness |

| Biocompatibility | Excellent, safe for implants | Excellent, widely used medically |

| Color Options | Multiple hues via voltage control | Single natural color |

| Cost | Higher due to processing | Lower, no extra treatment |

| Common Applications | Jewelry, medical devices, aerospace | Structural components, implants |

Introduction to Titanium: Anodized vs Untreated

Anodized titanium features a controlled oxide layer formed through an electrochemical process, enhancing corrosion resistance, surface hardness, and aesthetic color options compared to untreated titanium. Untreated titanium maintains its natural oxide film, offering excellent strength-to-weight ratio and biocompatibility but lacks the enhanced surface properties provided by anodization. The anodizing process tailors titanium's surface for specialized applications in aerospace, medical implants, and jewelry by improving durability and wear resistance.

What Is Anodized Titanium?

Anodized titanium is titanium that has undergone an electrochemical process called anodizing, which increases its natural oxide layer to enhance corrosion resistance and surface hardness. This process also allows the formation of vibrant colors without using dyes or paints, resulting from light interference on the oxide layer. Untreated titanium, in contrast, retains its raw metallic appearance and offers excellent strength and corrosion resistance but lacks the enhanced surface durability and aesthetic variation provided by anodizing.

Properties of Untreated Titanium

Untreated titanium exhibits exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility, making it ideal for aerospace, medical implants, and marine applications. It naturally forms a thin oxide layer that protects it from rust and chemical damage, though this layer provides limited color variety compared to anodized titanium. The untreated surface maintains a metallic silver-gray appearance, is highly durable, and requires minimal maintenance under normal environmental conditions.

Visual Differences: Anodized vs Untreated Titanium

Anodized titanium exhibits a vibrant, iridescent surface with hues ranging from deep blues to vivid purples, created through controlled oxidation processes that alter the oxide layer thickness. Untreated titanium maintains a natural, matte gray appearance with a subtle metallic sheen and lacks the color variation seen in anodized finishes. These visual differences not only impact aesthetic appeal but also reflect variations in surface properties influencing corrosion resistance and wear.

Durability and Corrosion Resistance Comparison

Anodized titanium exhibits significantly enhanced durability and corrosion resistance compared to untreated titanium due to its thicker oxide layer formed through the anodization process. This oxide layer provides superior protection against environmental factors such as saltwater, acids, and abrasion, extending the lifespan of titanium components in harsh conditions. Untreated titanium, while inherently corrosion-resistant, lacks this reinforced barrier, making anodized titanium the preferred choice for applications requiring long-term performance and resistance to wear.

Color Options and Aesthetics

Anodized titanium offers a wide spectrum of vibrant colors, achieved through controlled oxidation that creates oxide layers varying in thickness, producing hues from gold to deep blue and purple. Untreated titanium maintains its natural metallic silver-gray appearance, which is less customizable but valued for its raw, industrial look. The anodizing process enhances aesthetics by allowing tailored color options without compromising titanium's durability and corrosion resistance.

Application Areas for Anodized and Untreated Titanium

Anodized titanium is widely used in medical implants, aerospace components, and decorative architectural elements due to its enhanced corrosion resistance, improved surface hardness, and vibrant color options. Untreated titanium finds applications in industrial manufacturing, automotive parts, and marine environments where natural biocompatibility and raw material strength are prioritized. The distinct surface properties of anodized versus untreated titanium determine their suitability across various high-performance and aesthetic-focused industries.

Maintenance and Longevity

Anodized titanium offers enhanced corrosion resistance and surface hardness compared to untreated titanium, reducing maintenance needs and prolonging durability in harsh environments. Untreated titanium, while naturally corrosion-resistant and strong, may accumulate surface scratches and require more frequent cleaning to maintain its appearance. The anodizing process forms a protective oxide layer that improves wear resistance and color stability, significantly extending the lifespan of titanium components.

Cost-Effectiveness Analysis

Anodized titanium offers enhanced corrosion resistance and aesthetic appeal through a controlled oxide layer, increasing initial manufacturing costs by approximately 15-25% compared to untreated titanium. Despite the higher upfront expense, anodized titanium reduces long-term maintenance and replacement costs, proving more cost-effective in industrial applications where durability and longevity are critical. Untreated titanium, while cheaper initially, may incur greater expenditures over time due to surface degradation and increased wear.

Choosing the Best Titanium Finish for Your Needs

Anodized titanium offers enhanced corrosion resistance, increased surface hardness, and a vibrant range of color options compared to untreated titanium, making it ideal for applications requiring durability and aesthetics. Untreated titanium provides a natural, raw finish prized for its biocompatibility and lightweight strength, often favored in medical implants and aerospace components. Selecting the best titanium finish depends on the specific requirements for wear resistance, visual appeal, and environmental exposure in your project.

Anodized Titanium vs Untreated Titanium Infographic

materialdif.com

materialdif.com