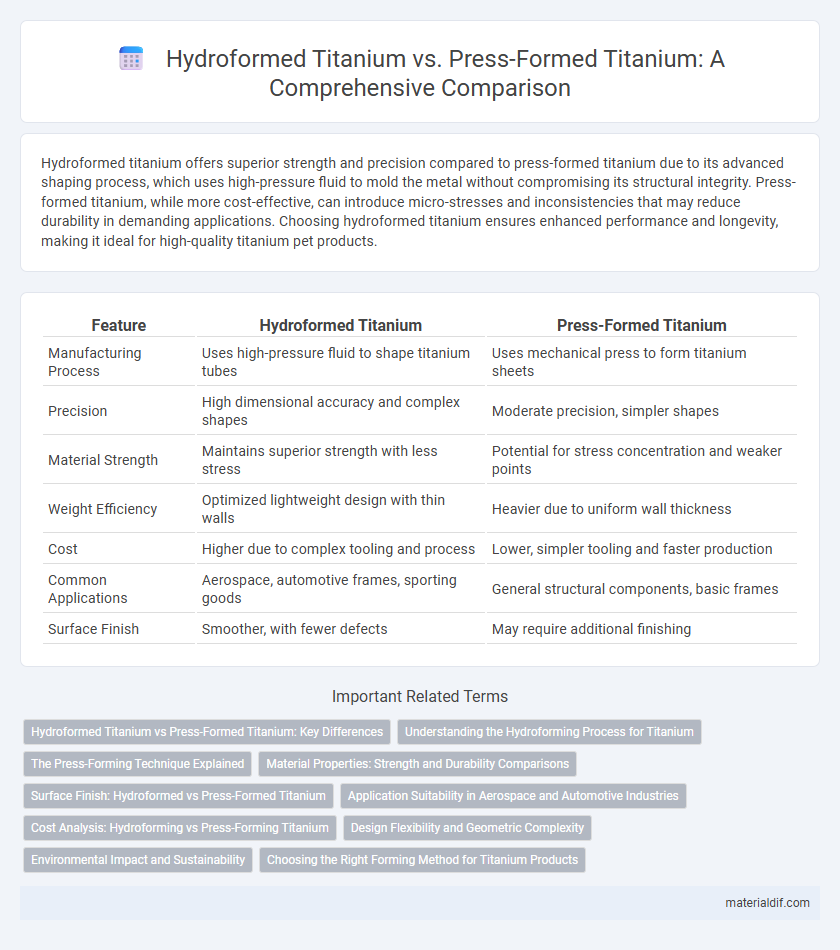

Hydroformed titanium offers superior strength and precision compared to press-formed titanium due to its advanced shaping process, which uses high-pressure fluid to mold the metal without compromising its structural integrity. Press-formed titanium, while more cost-effective, can introduce micro-stresses and inconsistencies that may reduce durability in demanding applications. Choosing hydroformed titanium ensures enhanced performance and longevity, making it ideal for high-quality titanium pet products.

Table of Comparison

| Feature | Hydroformed Titanium | Press-Formed Titanium |

|---|---|---|

| Manufacturing Process | Uses high-pressure fluid to shape titanium tubes | Uses mechanical press to form titanium sheets |

| Precision | High dimensional accuracy and complex shapes | Moderate precision, simpler shapes |

| Material Strength | Maintains superior strength with less stress | Potential for stress concentration and weaker points |

| Weight Efficiency | Optimized lightweight design with thin walls | Heavier due to uniform wall thickness |

| Cost | Higher due to complex tooling and process | Lower, simpler tooling and faster production |

| Common Applications | Aerospace, automotive frames, sporting goods | General structural components, basic frames |

| Surface Finish | Smoother, with fewer defects | May require additional finishing |

Hydroformed Titanium vs Press-Formed Titanium: Key Differences

Hydroformed titanium offers enhanced precision and uniformity due to the use of high-pressure fluid to shape complex geometries, which reduces the risk of structural defects compared to press-formed titanium. Press-forming involves mechanical force applied via dies, often leading to higher stress concentrations and limitations in achieving intricate designs. Hydroforming improves material efficiency and structural strength, making it ideal for aerospace and automotive applications requiring lightweight, durable titanium components.

Understanding the Hydroforming Process for Titanium

Hydroformed titanium involves shaping the metal using high-pressure fluid to expand it into a die, allowing for complex, lightweight, and seamless components with enhanced strength and durability. This process reduces material waste and preserves the titanium's structural integrity better than traditional press-forming, which relies on mechanical force and often results in increased grain distortion and potential weaknesses. Hydroforming Titanium is ideal for aerospace and automotive industries seeking precision-engineered parts with superior performance and corrosion resistance.

The Press-Forming Technique Explained

Press-forming titanium involves shaping titanium sheets by pressing them into a mold without heat, relying on mechanical pressure to achieve the desired contour. This technique preserves titanium's natural strength and corrosion resistance while offering cost-effective and precise production for complex geometries. Compared to hydroforming, press-forming typically requires simpler equipment and results in thicker, more uniformly dense titanium components suitable for aerospace and medical applications.

Material Properties: Strength and Durability Comparisons

Hydroformed titanium exhibits superior strength and durability compared to press-formed titanium due to its enhanced grain structure and reduced risk of material defects during the shaping process. The hydroforming technique applies uniform pressure that minimizes stress concentrations, resulting in improved fatigue resistance and higher tensile strength. Press-formed titanium often experiences uneven thickness and residual stresses, which can compromise long-term performance and structural integrity.

Surface Finish: Hydroformed vs Press-Formed Titanium

Hydroformed titanium offers a smoother, more uniform surface finish compared to press-formed titanium, thanks to its fluid pressure shaping process that reduces surface imperfections and tool marks. Press-formed titanium often exhibits minor surface inconsistencies and strain lines due to mechanical die contact and material stretching. This difference in surface quality makes hydroformed titanium ideal for applications requiring high cosmetic standards and reduced post-processing.

Application Suitability in Aerospace and Automotive Industries

Hydroformed titanium offers superior structural integrity and weight-saving advantages, making it ideal for complex aerospace components requiring high strength-to-weight ratios and precision shaping. Press-formed titanium, while more cost-effective, suits automotive applications where simpler geometries and moderate performance standards are sufficient. Both methods contribute to enhancing fuel efficiency and durability, but hydroforming is preferred for aerospace due to its ability to create lightweight, intricate parts without compromising material properties.

Cost Analysis: Hydroforming vs Press-Forming Titanium

Hydroformed titanium typically incurs higher upfront costs due to specialized equipment and tooling required for precise fluid pressure shaping, whereas press-formed titanium benefits from more established, cost-efficient stamping processes. In volume production, press-forming often reduces per-unit costs despite potential limitations in design complexity and material utilization. Evaluating total cost of ownership, including fabrication time, material waste, and post-processing, is critical for selecting the optimal forming technique for titanium components.

Design Flexibility and Geometric Complexity

Hydroformed titanium offers superior design flexibility and enables the creation of complex, intricate geometries that are difficult to achieve with traditional press-forming methods. This advanced manufacturing process uses high-pressure fluid to shape titanium, allowing for seamless, uniform components with fewer welds and joints. Press-formed titanium, while cost-effective for simpler shapes, struggles to replicate the detailed contours and fine features achievable through hydroforming, limiting its applications in high-performance industries like aerospace and automotive.

Environmental Impact and Sustainability

Hydroformed titanium offers a more sustainable manufacturing process compared to press-formed titanium due to its reduced material waste and lower energy consumption. This method shapes titanium using high-pressure fluid, minimizing the need for multiple forming steps and decreasing carbon emissions associated with traditional stamping. Press-formed titanium, while effective for mass production, generates higher scrap rates and consumes more energy, leading to a larger environmental footprint.

Choosing the Right Forming Method for Titanium Products

Hydroformed titanium offers superior structural integrity and uniform thickness, ideal for complex shapes requiring high strength-to-weight ratios, such as aerospace components. Press-formed titanium suits simpler geometries with lower production costs, making it suitable for automotive panels and basic industrial parts. Selecting the right forming method depends on application demands, production volume, and mechanical property requirements of the titanium product.

Hydroformed Titanium vs Press-Formed Titanium Infographic

materialdif.com

materialdif.com