CPTi offers superior corrosion resistance and biocompatibility compared to Ti-6Al-4V, making it ideal for long-term implant applications. Ti-6Al-4V exhibits higher strength and fatigue resistance but contains aluminum and vanadium, which may cause adverse biological reactions. Choosing between CPTi and Ti-6Al-4V depends on balancing mechanical performance with biocompatibility requirements in medical device design.

Table of Comparison

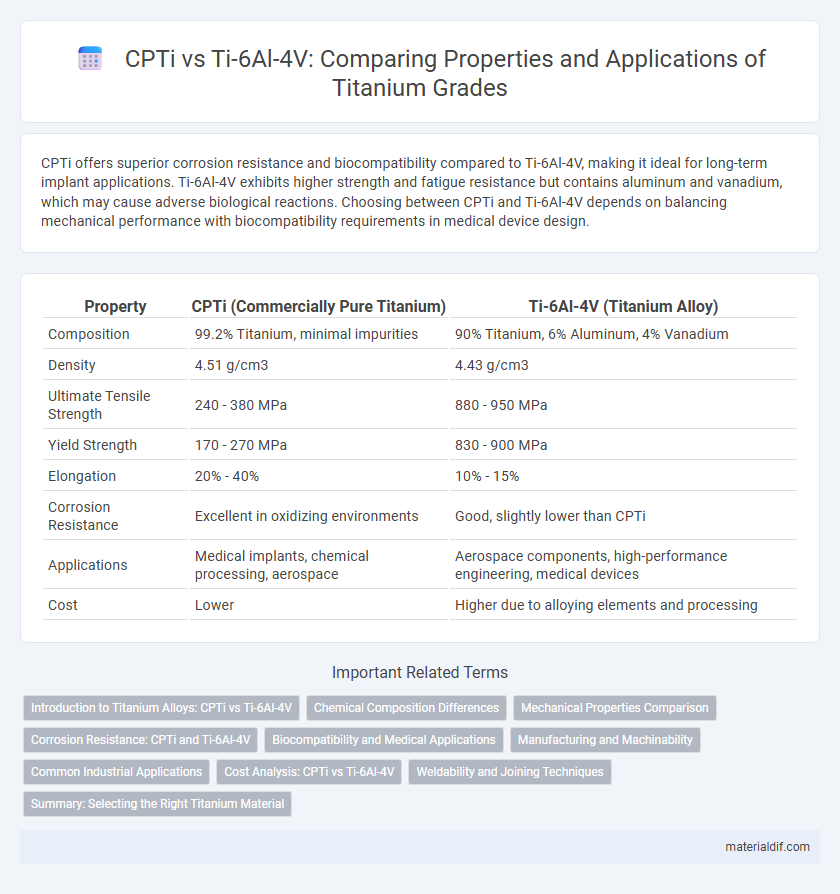

| Property | CPTi (Commercially Pure Titanium) | Ti-6Al-4V (Titanium Alloy) |

|---|---|---|

| Composition | 99.2% Titanium, minimal impurities | 90% Titanium, 6% Aluminum, 4% Vanadium |

| Density | 4.51 g/cm3 | 4.43 g/cm3 |

| Ultimate Tensile Strength | 240 - 380 MPa | 880 - 950 MPa |

| Yield Strength | 170 - 270 MPa | 830 - 900 MPa |

| Elongation | 20% - 40% | 10% - 15% |

| Corrosion Resistance | Excellent in oxidizing environments | Good, slightly lower than CPTi |

| Applications | Medical implants, chemical processing, aerospace | Aerospace components, high-performance engineering, medical devices |

| Cost | Lower | Higher due to alloying elements and processing |

Introduction to Titanium Alloys: CPTi vs Ti-6Al-4V

Commercially Pure Titanium (CPTi) offers excellent corrosion resistance and biocompatibility, making it ideal for medical implants and chemical processing equipment. Ti-6Al-4V, an alpha-beta titanium alloy, provides superior strength and fatigue resistance, widely used in aerospace, automotive, and high-performance engineering applications. The selection between CPTi and Ti-6Al-4V depends on the specific balance of mechanical properties, corrosion resistance, and cost requirements of the intended application.

Chemical Composition Differences

CPTi (Commercially Pure Titanium) primarily consists of over 99% titanium with minimal impurities like oxygen, nitrogen, and iron, ensuring excellent corrosion resistance and biocompatibility. Ti-6Al-4V, an alpha-beta titanium alloy, contains approximately 6% aluminum and 4% vanadium, which significantly enhances its strength and fatigue resistance compared to CPTi. The addition of aluminum stabilizes the alpha phase while vanadium stabilizes the beta phase, resulting in a chemically optimized balance for structural applications.

Mechanical Properties Comparison

CPTi (Commercially Pure Titanium) exhibits superior corrosion resistance and excellent ductility but has lower tensile strength compared to the Ti-6Al-4V alloy, which offers enhanced mechanical strength and hardness due to its aluminum and vanadium content. Ti-6Al-4V demonstrates higher yield strength, typically around 880 MPa, whereas CPTi's yield strength ranges between 170-380 MPa depending on grade. Fatigue resistance and fracture toughness of Ti-6Al-4V surpass those of CPTi, making the alloy more suitable for high-stress applications in aerospace and biomedical fields.

Corrosion Resistance: CPTi and Ti-6Al-4V

Commercially Pure Titanium (CPTi) exhibits superior corrosion resistance compared to Ti-6Al-4V due to its nearly pure composition, which forms a highly stable titanium oxide passive layer in diverse environments. Ti-6Al-4V, an alpha-beta titanium alloy, offers high strength but demonstrates slightly reduced corrosion resistance, especially in acidic or chloride-rich conditions, because of the presence of aluminum and vanadium. CPTi is favored in medical and marine applications requiring maximum corrosion resistance, while Ti-6Al-4V is selected for aerospace and structural uses balancing strength and corrosion protection.

Biocompatibility and Medical Applications

CPTi (Commercially Pure Titanium) exhibits superior biocompatibility due to its minimal alloying elements, reducing the risk of adverse tissue reactions, making it ideal for implants such as dental fixtures and bone plates. Ti-6Al-4V alloy, while offering enhanced mechanical strength and fatigue resistance, poses potential concerns regarding aluminum and vanadium ion release, impacting long-term biocompatibility in orthopedic and dental implants. Medical applications prioritize CPTi for patient safety and osseointegration, whereas Ti-6Al-4V is preferred where high strength-to-weight ratio and durability are critical.

Manufacturing and Machinability

CPTi (Commercially Pure Titanium) offers superior machinability compared to Ti-6Al-4V due to its lower alloy content and reduced hardness, resulting in less tool wear and easier cutting processes. Ti-6Al-4V, an alpha-beta titanium alloy, presents challenges in manufacturing because of its higher strength and toughness, necessitating specialized cutting tools and optimized machining parameters. While CPTi allows for faster machining speeds and lower production costs, Ti-6Al-4V requires precision techniques to maintain dimensional accuracy and surface integrity in critical aerospace and medical applications.

Common Industrial Applications

CPTi (Commercially Pure Titanium) is widely used in aerospace, chemical processing, and marine industries due to its excellent corrosion resistance and good strength-to-weight ratio. Ti-6Al-4V alloy, with higher tensile strength and fatigue resistance, is preferred in aerospace, biomedical implants, and high-performance automotive sectors for critical load-bearing applications. Both materials serve distinct industrial roles, with CPTi favored for corrosion environments and Ti-6Al-4V chosen for structural components requiring enhanced mechanical properties.

Cost Analysis: CPTi vs Ti-6Al-4V

Commercially Pure Titanium (CPTi) is generally more cost-effective than Ti-6Al-4V due to its simpler alloy composition and lower manufacturing complexity. Ti-6Al-4V, containing aluminum and vanadium, offers superior strength and corrosion resistance but entails higher material and processing costs. The cost analysis reveals CPTi's advantage in budget-sensitive applications, while Ti-6Al-4V justifies expenses in high-performance demands.

Weldability and Joining Techniques

CPTi (Commercially Pure Titanium) exhibits superior weldability compared to Ti-6Al-4V due to its lower alloy content, reducing the risk of cracking and oxidation during welding. Ti-6Al-4V requires controlled atmospheres such as argon shielding in TIG or electron beam welding to prevent embrittlement and maintain joint integrity. Advanced joining techniques like friction stir welding and laser welding enhance weld quality for both alloys, though CPTi generally allows for more straightforward procedures.

Summary: Selecting the Right Titanium Material

CPTi offers superior corrosion resistance and biocompatibility, making it ideal for biomedical implants and chemical processing equipment. Ti-6Al-4V provides higher strength and fatigue resistance, preferred in aerospace and automotive applications requiring durability and lightweight performance. Selecting the right titanium material depends on balancing mechanical properties with corrosion behavior to suit specific operational environments.

CPTi vs Ti-6Al-4V Infographic

materialdif.com

materialdif.com