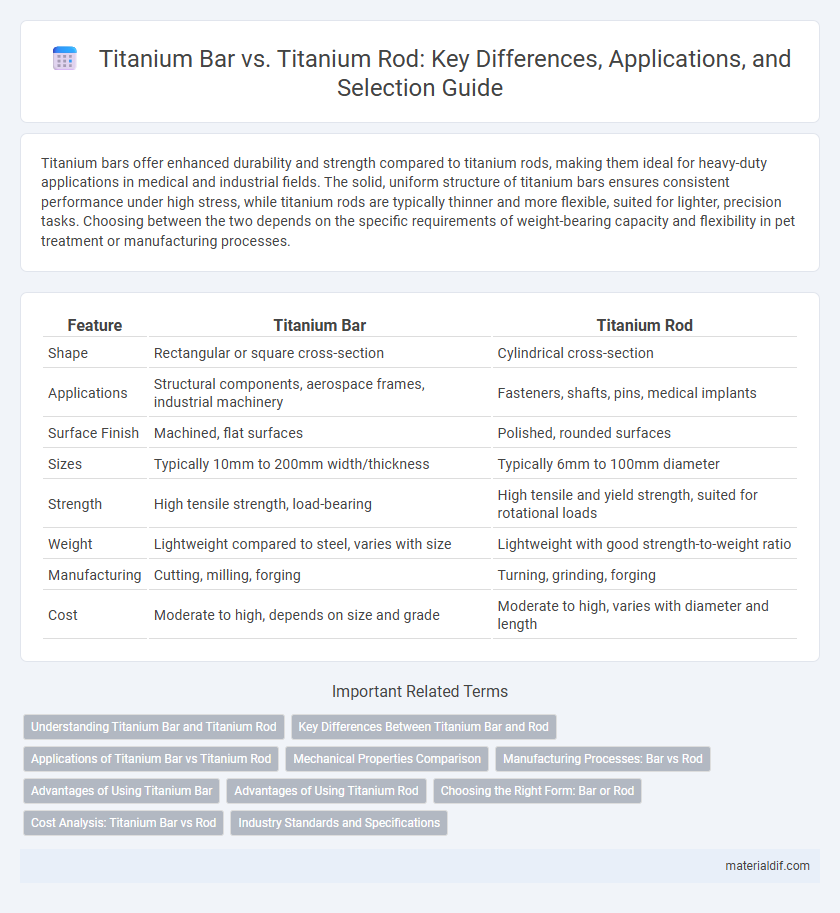

Titanium bars offer enhanced durability and strength compared to titanium rods, making them ideal for heavy-duty applications in medical and industrial fields. The solid, uniform structure of titanium bars ensures consistent performance under high stress, while titanium rods are typically thinner and more flexible, suited for lighter, precision tasks. Choosing between the two depends on the specific requirements of weight-bearing capacity and flexibility in pet treatment or manufacturing processes.

Table of Comparison

| Feature | Titanium Bar | Titanium Rod |

|---|---|---|

| Shape | Rectangular or square cross-section | Cylindrical cross-section |

| Applications | Structural components, aerospace frames, industrial machinery | Fasteners, shafts, pins, medical implants |

| Surface Finish | Machined, flat surfaces | Polished, rounded surfaces |

| Sizes | Typically 10mm to 200mm width/thickness | Typically 6mm to 100mm diameter |

| Strength | High tensile strength, load-bearing | High tensile and yield strength, suited for rotational loads |

| Weight | Lightweight compared to steel, varies with size | Lightweight with good strength-to-weight ratio |

| Manufacturing | Cutting, milling, forging | Turning, grinding, forging |

| Cost | Moderate to high, depends on size and grade | Moderate to high, varies with diameter and length |

Understanding Titanium Bar and Titanium Rod

Titanium bars and rods differ primarily in shape and manufacturing processes, with bars typically having flat or square cross-sections while rods are round and cylindrical. Both materials offer excellent strength-to-weight ratios, corrosion resistance, and biocompatibility, making them ideal for aerospace, medical implants, and industrial applications. Understanding the specific dimensions, machining requirements, and mechanical properties of titanium bars and rods is crucial for selecting the right form for precision engineering and structural projects.

Key Differences Between Titanium Bar and Rod

Titanium bars and rods differ primarily in their shape and manufacturing process, with bars typically being rectangular or square and rods being cylindrical. The choice between titanium bar and rod depends on application requirements such as structural strength, machinability, and specific design constraints. Titanium bars offer greater surface area for machining complex components, while rods are preferred for rotational symmetry and parts like fasteners or shafts.

Applications of Titanium Bar vs Titanium Rod

Titanium bars are widely used in aerospace, medical implants, and automotive industries due to their excellent strength-to-weight ratio and corrosion resistance, enabling precise machining for complex components. Titanium rods find applications in construction, marine frameworks, and chemical processing equipment, where their durability and high tensile strength support structural integrity. Both forms optimize performance in extreme environments but differ in shape suitability, with bars preferred for detailed fabrication and rods for straightforward, load-bearing uses.

Mechanical Properties Comparison

Titanium bars and rods differ primarily in their mechanical properties due to variations in manufacturing processes and dimensions. Titanium rods typically exhibit higher tensile strength and better fatigue resistance, making them suitable for high-stress applications, while titanium bars offer enhanced toughness and impact resistance ideal for structural uses. Both forms maintain exceptional corrosion resistance and a high strength-to-weight ratio, crucial for aerospace, medical implants, and industrial machinery.

Manufacturing Processes: Bar vs Rod

Titanium bars are typically produced through hot rolling or forging, creating solid, elongated shapes with consistent cross-sections ideal for machining and structural applications. Titanium rods often derive from extrusion processes, pushing heated titanium billets through shaped dies to form cylindrical or custom profiles with enhanced mechanical properties and surface finishes. The manufacturing choice influences the microstructure, dimensional tolerances, and application suitability of titanium bars versus rods.

Advantages of Using Titanium Bar

Titanium bars offer superior strength-to-weight ratios compared to rods, making them ideal for high-performance applications in aerospace, medical, and marine industries. Their uniform cross-sectional shape provides greater machinability and precision in manufacturing complex components. Enhanced corrosion resistance and durability ensure titanium bars deliver longer service life under harsh environmental conditions.

Advantages of Using Titanium Rod

Titanium rods offer superior strength-to-weight ratio compared to titanium bars, making them ideal for high-performance applications requiring lightweight durability. Their uniform cross-section allows for consistent mechanical properties, enhancing reliability in aerospace, medical implants, and automotive components. Titanium rods also provide better machinability and corrosion resistance, extending the lifespan of critical parts in demanding environments.

Choosing the Right Form: Bar or Rod

Titanium bars offer uniform thickness and smooth surfaces, making them ideal for precision machining and structural applications requiring consistent dimensions. Titanium rods typically feature a round cross-section and are preferred for applications demanding high strength-to-weight ratios and where shaping or forging is involved. Selecting between titanium bar and rod hinges on project requirements, such as machining needs, mechanical properties, and the component's final design.

Cost Analysis: Titanium Bar vs Rod

Titanium bars generally cost more than titanium rods due to their larger cross-sectional area and additional processing required for precise dimensional tolerances. The price difference is influenced by machining complexity, with rods often requiring less finishing, reducing labor expenses. Material yield and scrap rates also impact cost efficiency, where bars may result in higher waste compared to rods optimized for specific applications.

Industry Standards and Specifications

Titanium bars and rods adhere to strict industry standards such as ASTM B348 and AMS 4928 to ensure material integrity and performance in aerospace, medical, and chemical processing applications. Titanium bars typically feature a rectangular or square cross-section, complying with dimensional tolerances critical for machining and fabrication, while titanium rods offer cylindrical forms optimized for mechanical strength and uniformity. Both forms undergo certification and traceability per ISO 9001 quality management systems to meet rigorous specifications for corrosion resistance, tensile strength, and biocompatibility.

Titanium Bar vs Titanium Rod Infographic

materialdif.com

materialdif.com