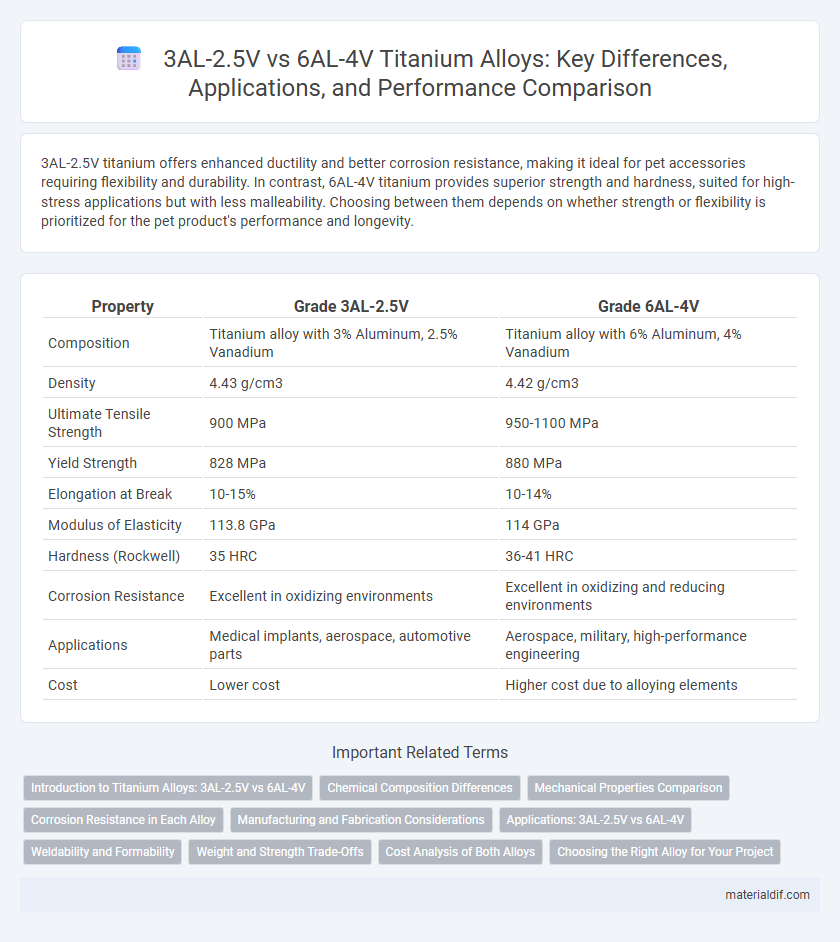

3AL-2.5V titanium offers enhanced ductility and better corrosion resistance, making it ideal for pet accessories requiring flexibility and durability. In contrast, 6AL-4V titanium provides superior strength and hardness, suited for high-stress applications but with less malleability. Choosing between them depends on whether strength or flexibility is prioritized for the pet product's performance and longevity.

Table of Comparison

| Property | Grade 3AL-2.5V | Grade 6AL-4V |

|---|---|---|

| Composition | Titanium alloy with 3% Aluminum, 2.5% Vanadium | Titanium alloy with 6% Aluminum, 4% Vanadium |

| Density | 4.43 g/cm3 | 4.42 g/cm3 |

| Ultimate Tensile Strength | 900 MPa | 950-1100 MPa |

| Yield Strength | 828 MPa | 880 MPa |

| Elongation at Break | 10-15% | 10-14% |

| Modulus of Elasticity | 113.8 GPa | 114 GPa |

| Hardness (Rockwell) | 35 HRC | 36-41 HRC |

| Corrosion Resistance | Excellent in oxidizing environments | Excellent in oxidizing and reducing environments |

| Applications | Medical implants, aerospace, automotive parts | Aerospace, military, high-performance engineering |

| Cost | Lower cost | Higher cost due to alloying elements |

Introduction to Titanium Alloys: 3AL-2.5V vs 6AL-4V

3Al-2.5V and 6Al-4V are two widely used titanium alloys distinguished by their aluminum and vanadium content, influencing their mechanical properties and applications. The 3Al-2.5V alloy offers enhanced corrosion resistance and improved weldability, making it suitable for aerospace components requiring durability under oxidative environments. In contrast, 6Al-4V provides higher strength and fatigue resistance, commonly utilized in aerospace and medical implants where structural integrity is critical.

Chemical Composition Differences

3AL-2.5V titanium alloy contains approximately 3% aluminum and 2.5% vanadium, providing a balance of strength and corrosion resistance suitable for aerospace applications. In contrast, 6AL-4V alloy has about 6% aluminum and 4% vanadium, resulting in higher strength and improved mechanical properties for high-performance engineering uses. The increased aluminum and vanadium content in 6AL-4V significantly enhances its tensile strength and fatigue resistance compared to 3AL-2.5V.

Mechanical Properties Comparison

3AL-2.5V titanium alloy exhibits higher fatigue resistance and superior corrosion performance, making it ideal for aerospace applications requiring durability. 6AL-4V titanium offers greater tensile strength and improved fracture toughness, suitable for structural components under high stress. Both alloys provide excellent strength-to-weight ratios, but 6AL-4V typically surpasses 3AL-2.5V in yield strength and elongation.

Corrosion Resistance in Each Alloy

3AL-2.5V titanium alloy exhibits superior corrosion resistance compared to 6AL-4V due to its lower aluminum content and higher vanadium concentration, which enhances passivation in aggressive environments. The 3AL-2.5V alloy shows greater resistance to chloride-induced pitting and stress corrosion cracking, making it ideal for marine and chemical processing applications. In contrast, 6AL-4V, while strong and versatile, is more prone to localized corrosion under harsh conditions, limiting its use in highly corrosive media.

Manufacturing and Fabrication Considerations

3AL-2.5V titanium alloy offers easier manufacturing and better weldability compared to 6AL-4V due to its lower strength and improved ductility, which reduces tool wear and machining costs. 6AL-4V, while stronger and more widely used in aerospace, requires more precise control during fabrication processes such as heat treatment and forming, increasing production complexity and costs. Fabricators often prefer 3AL-2.5V for components requiring complex shapes and intricate weld structures, whereas 6AL-4V is favored for high-performance applications demanding superior mechanical properties.

Applications: 3AL-2.5V vs 6AL-4V

3AL-2.5V titanium alloy, known for its higher corrosion resistance, finds extensive use in marine and chemical processing applications where durability against harsh environments is critical. In contrast, 6AL-4V titanium alloy offers superior strength and is commonly utilized in aerospace, automotive, and medical implants requiring high strength-to-weight ratios. The choice between 3AL-2.5V and 6AL-4V depends on application-specific demands for corrosion resistance versus mechanical strength.

Weldability and Formability

3AL-2.5V titanium alloy exhibits superior weldability compared to 6AL-4V due to its lower aluminum and vanadium content, reducing the risk of cracking during welding processes. Formability is enhanced in 3AL-2.5V because it maintains better ductility and resistance to strain hardening, making it ideal for complex shapes and fabrication. In contrast, 6AL-4V, while stronger, requires more precise control during welding and has limited formability due to its higher strength and lower ductility.

Weight and Strength Trade-Offs

3AL-2.5V titanium alloy offers a significant weight reduction of approximately 10% compared to 6AL-4V, making it ideal for aerospace and automotive applications where minimizing mass is critical. Despite having slightly lower ultimate tensile strength, around 895 MPa versus 950 MPa for 6AL-4V, 3AL-2.5V maintains excellent fracture toughness and fatigue resistance. This alloy balances high strength with reduced density, optimizing performance when weight savings are a priority over maximum strength.

Cost Analysis of Both Alloys

3AL-2.5V titanium alloy generally offers a more cost-effective solution compared to 6AL-4V due to its lower alloying element content and simplified processing requirements. The price difference stems from the reduced amounts of aluminum and vanadium in 3AL-2.5V, which decreases raw material costs and enhances machinability, leading to lower manufacturing expenses. For applications demanding high strength-to-weight ratios, 6AL-4V's superior mechanical properties justify its higher cost despite the increased price per kilogram.

Choosing the Right Alloy for Your Project

3AL-2.5V titanium alloy offers superior corrosion resistance and higher strength-to-weight ratio, making it ideal for aerospace and medical applications where durability and biocompatibility are critical. 6AL-4V remains the industry standard for general use due to its excellent toughness and versatility across aerospace, automotive, and marine projects. Selecting the right alloy depends on project requirements such as mechanical strength, corrosion environment, and weight constraints.

3AL-2.5V vs 6AL-4V Infographic

materialdif.com

materialdif.com