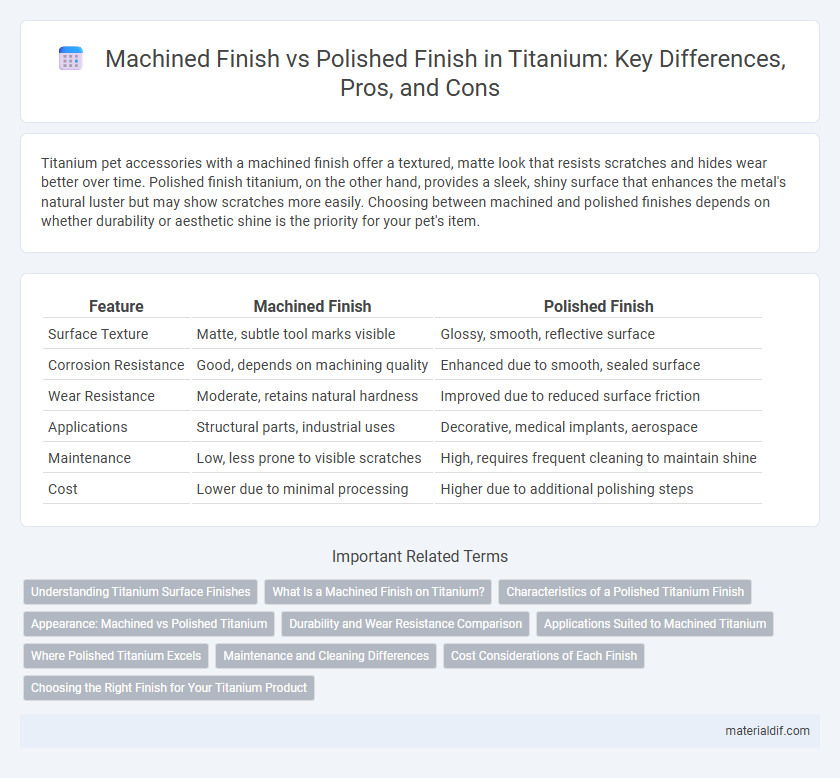

Titanium pet accessories with a machined finish offer a textured, matte look that resists scratches and hides wear better over time. Polished finish titanium, on the other hand, provides a sleek, shiny surface that enhances the metal's natural luster but may show scratches more easily. Choosing between machined and polished finishes depends on whether durability or aesthetic shine is the priority for your pet's item.

Table of Comparison

| Feature | Machined Finish | Polished Finish |

|---|---|---|

| Surface Texture | Matte, subtle tool marks visible | Glossy, smooth, reflective surface |

| Corrosion Resistance | Good, depends on machining quality | Enhanced due to smooth, sealed surface |

| Wear Resistance | Moderate, retains natural hardness | Improved due to reduced surface friction |

| Applications | Structural parts, industrial uses | Decorative, medical implants, aerospace |

| Maintenance | Low, less prone to visible scratches | High, requires frequent cleaning to maintain shine |

| Cost | Lower due to minimal processing | Higher due to additional polishing steps |

Understanding Titanium Surface Finishes

Machined finish on titanium exhibits a textured, matte appearance with visible tool marks, enhancing grip and reducing glare, making it ideal for industrial and aerospace components. Polished finish, by contrast, produces a smooth, reflective surface that improves corrosion resistance and aesthetic appeal, commonly used in medical implants and jewelry. Understanding these surface finishes is crucial for selecting the appropriate titanium treatment based on functional requirements and environmental exposure.

What Is a Machined Finish on Titanium?

A machined finish on titanium refers to the surface texture created by precision CNC machining processes, leaving visible tool marks and a matte appearance. This finish enhances grip and reduces glare, making it ideal for industrial applications and components requiring functional surface properties. Compared to a polished finish, a machined finish maintains the titanium's natural durability while providing a tactile, non-reflective surface.

Characteristics of a Polished Titanium Finish

A polished titanium finish features a smooth, reflective surface achieved through fine abrasive processes, enhancing corrosion resistance and aesthetic appeal. This finish highlights titanium's natural metallic luster while providing a harder, more durable outer layer that resists scratches and tarnishing. Polished titanium is commonly used in high-end applications such as jewelry, aerospace components, and medical instruments due to its combination of strength and elegant appearance.

Appearance: Machined vs Polished Titanium

Machined titanium finish exhibits a matte texture with visible tool marks that emphasize the metal's industrial and raw aesthetic, while polished titanium offers a smooth, reflective surface with a bright, mirror-like appearance. The machined finish highlights the metal's natural grain and provides a more tactile, rugged look suitable for functional and utilitarian designs. Polished titanium enhances visual appeal through high gloss and luster, making it ideal for decorative applications where elegance and brilliance are prioritized.

Durability and Wear Resistance Comparison

Machined finish titanium surfaces exhibit superior durability due to their textured nature, which better resists scratches and wear compared to polished finishes. Polished titanium, while more aesthetically reflective, is prone to micro-abrasions that reduce long-term wear resistance under harsh conditions. Industrial applications favor machined finishes for enhanced longevity in environments subject to mechanical stress and abrasion.

Applications Suited to Machined Titanium

Machined titanium finish offers superior grip and wear resistance, making it ideal for aerospace components, medical implants, and industrial machinery parts where precision and durability are critical. The textured surface enhances bonding with adhesives and coatings, improving performance in high-stress environments. Machined finish titanium also reduces glare and reflections, benefiting military and outdoor equipment applications.

Where Polished Titanium Excels

Polished titanium excels in applications where corrosion resistance and biocompatibility are critical, such as in medical implants and aerospace components. Its smooth, reflective surface reduces friction and prevents bacterial accumulation, enhancing durability and hygiene. This finish also provides superior aesthetic appeal, making it ideal for luxury watches and jewelry.

Maintenance and Cleaning Differences

Machined finish titanium features a textured surface that hides scratches and requires less frequent cleaning, making it ideal for low-maintenance applications. Polished finish titanium has a smooth, reflective surface that shows fingerprints and smudges easily, necessitating regular cleaning with mild detergents to maintain its shine. Both finishes resist corrosion, but machined finishes tolerate abrasive cleaning methods better, while polished finishes require gentle cleaning to avoid surface dulling.

Cost Considerations of Each Finish

Machined finish titanium typically costs less due to minimal processing requirements, involving basic cutting and surface treatment that reduce labor and time expenses. Polished finish demands extensive surface preparation, including grinding, buffing, and multiple polishing stages, which increases both material waste and labor costs. Choosing between machined and polished finishes often depends on budget constraints, with machined finishes offering economic advantages for functional applications and polished finishes favored for aesthetic or corrosion-resistant needs despite higher costs.

Choosing the Right Finish for Your Titanium Product

Machined finish on titanium provides a textured, matte surface ideal for applications requiring enhanced grip and reduced glare, while polished finish delivers a smooth, reflective appearance suited for aesthetic appeal and corrosion resistance. Selecting the right finish depends on the titanium product's functional needs and environmental exposure, where machined finishes excel in industrial and aerospace contexts, and polished finishes are preferred in medical implants and jewelry for their biocompatibility and ease of cleaning. Understanding these finish variations optimizes titanium's performance by balancing durability, appearance, and maintenance requirements.

Machined Finish vs Polished Finish Infographic

materialdif.com

materialdif.com