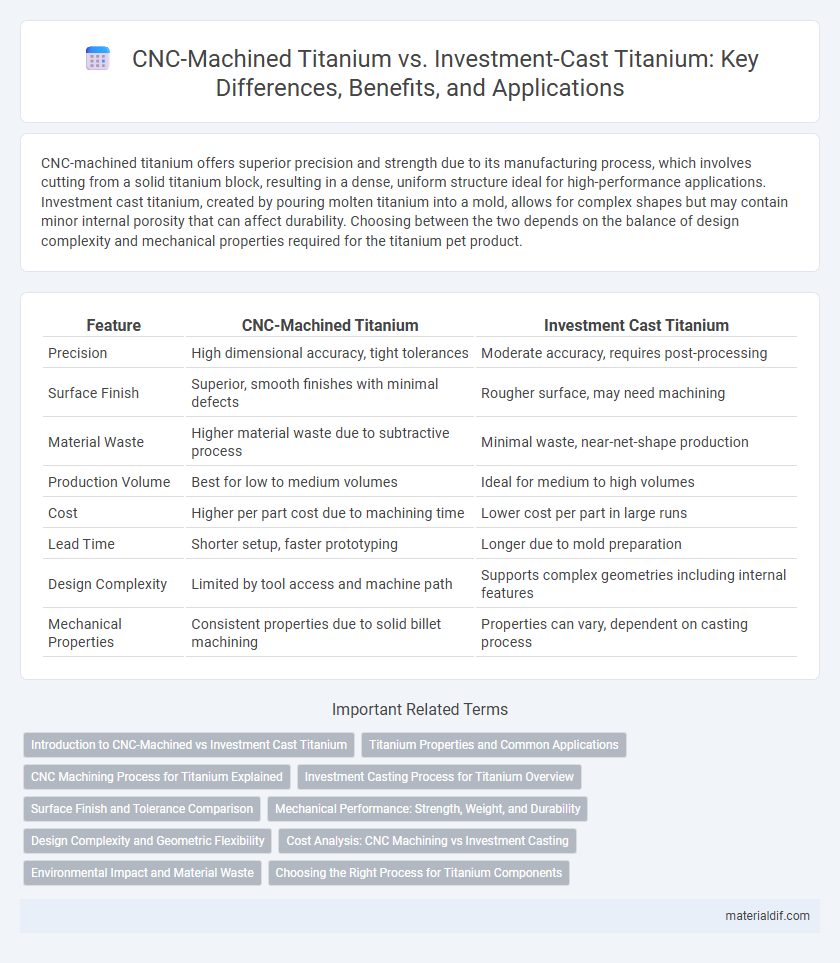

CNC-machined titanium offers superior precision and strength due to its manufacturing process, which involves cutting from a solid titanium block, resulting in a dense, uniform structure ideal for high-performance applications. Investment cast titanium, created by pouring molten titanium into a mold, allows for complex shapes but may contain minor internal porosity that can affect durability. Choosing between the two depends on the balance of design complexity and mechanical properties required for the titanium pet product.

Table of Comparison

| Feature | CNC-Machined Titanium | Investment Cast Titanium |

|---|---|---|

| Precision | High dimensional accuracy, tight tolerances | Moderate accuracy, requires post-processing |

| Surface Finish | Superior, smooth finishes with minimal defects | Rougher surface, may need machining |

| Material Waste | Higher material waste due to subtractive process | Minimal waste, near-net-shape production |

| Production Volume | Best for low to medium volumes | Ideal for medium to high volumes |

| Cost | Higher per part cost due to machining time | Lower cost per part in large runs |

| Lead Time | Shorter setup, faster prototyping | Longer due to mold preparation |

| Design Complexity | Limited by tool access and machine path | Supports complex geometries including internal features |

| Mechanical Properties | Consistent properties due to solid billet machining | Properties can vary, dependent on casting process |

Introduction to CNC-Machined vs Investment Cast Titanium

CNC-machined titanium offers precise dimensional accuracy and superior surface finish compared to investment cast titanium, which is typically favored for complex geometries and high-volume production runs. CNC machining provides detailed control over tolerances, making it ideal for aerospace and medical applications requiring critical performance standards. Investment casting, while cost-effective for intricate parts, may have limitations in mechanical properties and surface quality when compared to CNC-machined titanium.

Titanium Properties and Common Applications

CNC-machined titanium offers superior dimensional accuracy and surface finish due to precise subtractive manufacturing, making it ideal for aerospace components and medical implants where tight tolerances are critical. Investment cast titanium provides complex geometries with excellent strength-to-weight ratios, frequently used in automotive parts, aerospace engine components, and chemical processing equipment. Both methods capitalize on titanium's exceptional corrosion resistance, high strength, and biocompatibility, but selection depends on design complexity and production volume requirements.

CNC Machining Process for Titanium Explained

CNC-machined titanium involves precise subtractive manufacturing where computer-controlled tools mill titanium billets to exact specifications, ensuring superior dimensional accuracy and surface finish compared to investment casting. The CNC machining process for titanium requires specialized tooling and optimized machining parameters to manage titanium's high strength and poor thermal conductivity, reducing risks of tool wear and material deformation. This method produces components with enhanced mechanical properties and tighter tolerances, critical for aerospace, medical, and high-performance engineering applications.

Investment Casting Process for Titanium Overview

Investment cast titanium involves creating intricate, high-precision components through a multi-step process that uses a wax pattern coated with ceramic material to form a mold. This method achieves superior surface finishes and complex geometries unattainable by traditional machining, making it ideal for aerospace and medical applications. The process ensures minimal material waste and excellent mechanical properties due to controlled solidification and reduced residual stresses.

Surface Finish and Tolerance Comparison

CNC-machined titanium offers superior surface finish with smoother, more precise contours compared to investment cast titanium, which often requires additional finishing processes to achieve similar quality. Tolerances in CNC machining are typically tighter, around +-0.002 inches, enabling high-precision components, whereas investment casting tolerances generally range from +-0.005 to +-0.010 inches due to the nature of mold shrinkage and deformation. These differences make CNC-machined titanium ideal for aerospace and medical applications demanding stringent dimensional accuracy and excellent surface characteristics.

Mechanical Performance: Strength, Weight, and Durability

CNC-machined titanium offers superior mechanical performance with higher strength and precise dimensional tolerances compared to investment cast titanium, resulting in enhanced structural integrity and reliability. The machining process preserves the alloy's inherent low density, maintaining titanium's renowned lightweight advantage critical for aerospace and medical applications. Investment cast titanium, while cost-effective for complex shapes, often exhibits reduced durability due to slight porosity and grain inconsistencies affecting fatigue resistance and overall longevity.

Design Complexity and Geometric Flexibility

CNC-machined titanium offers superior precision and geometric flexibility, enabling the production of intricate and highly detailed components with tight tolerances. Investment cast titanium excels in fabricating complex shapes that are difficult to machine due to its ability to create near-net shapes, reducing material waste and machining time. The selection between CNC machining and investment casting hinges on design complexity, with CNC machining favored for detailed, small-batch parts and investment casting preferred for geometrically intricate, larger-volume production.

Cost Analysis: CNC Machining vs Investment Casting

CNC-machined titanium typically incurs higher costs due to longer production times and extensive material waste compared to investment casting, which benefits from lower per-part expenses in large volume runs. Investment casting allows for complex geometries and near-net-shape production, reducing post-processing and machining costs, making it more cost-effective for medium to high quantities. CNC machining offers superior precision and surface finish but is financially viable primarily in low-volume, prototype, or custom titanium component manufacturing.

Environmental Impact and Material Waste

CNC-machined titanium generates more material waste compared to investment cast titanium due to the subtractive manufacturing process that removes excess metal from a solid block. Investment casting produces near-net shape components, significantly reducing scrap material and energy consumption during production. The lower waste output and energy efficiency of investment cast titanium contribute to a smaller environmental footprint compared to CNC machining methods.

Choosing the Right Process for Titanium Components

CNC-machined titanium offers high precision and superior surface finish, making it ideal for complex components with tight tolerances in aerospace and medical industries. Investment cast titanium provides design flexibility and cost efficiency for producing intricate shapes and larger quantities without extensive material waste. Selecting the right process depends on part complexity, production volume, and budget constraints to optimize performance and cost-effectiveness.

CNC-Machined Titanium vs Investment Cast Titanium Infographic

materialdif.com

materialdif.com