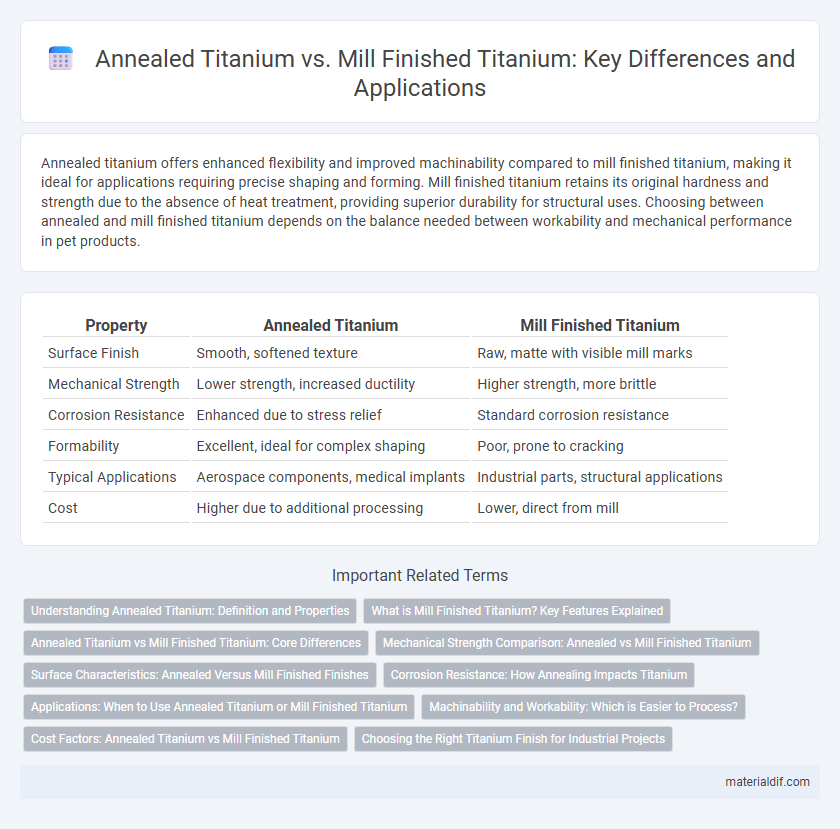

Annealed titanium offers enhanced flexibility and improved machinability compared to mill finished titanium, making it ideal for applications requiring precise shaping and forming. Mill finished titanium retains its original hardness and strength due to the absence of heat treatment, providing superior durability for structural uses. Choosing between annealed and mill finished titanium depends on the balance needed between workability and mechanical performance in pet products.

Table of Comparison

| Property | Annealed Titanium | Mill Finished Titanium |

|---|---|---|

| Surface Finish | Smooth, softened texture | Raw, matte with visible mill marks |

| Mechanical Strength | Lower strength, increased ductility | Higher strength, more brittle |

| Corrosion Resistance | Enhanced due to stress relief | Standard corrosion resistance |

| Formability | Excellent, ideal for complex shaping | Poor, prone to cracking |

| Typical Applications | Aerospace components, medical implants | Industrial parts, structural applications |

| Cost | Higher due to additional processing | Lower, direct from mill |

Understanding Annealed Titanium: Definition and Properties

Annealed titanium undergoes a heat treatment process that enhances its ductility and reduces internal stresses, resulting in improved formability compared to mill finished titanium. This process softens the metal, making it more malleable while maintaining its strength and corrosion resistance, which is critical for applications requiring bending or shaping. Mill finished titanium, by contrast, retains its original hardness and stress levels, making it less pliable but suitable for applications demanding higher structural integrity without deformation.

What is Mill Finished Titanium? Key Features Explained

Mill finished titanium refers to titanium that has been processed through initial rolling and shaping but has not undergone any further surface treatments or finishes. Key features of mill finished titanium include a rough, matte surface texture, the presence of mill scale or oxidation, and natural mechanical properties such as high strength, corrosion resistance, and lightweight. This form is often selected for applications where additional finishing is unnecessary or where further customization will be applied.

Annealed Titanium vs Mill Finished Titanium: Core Differences

Annealed titanium undergoes a heat treatment process that enhances its ductility, making it more malleable and easier to work with compared to mill finished titanium, which retains its original hardness and strength from the manufacturing process. Mill finished titanium exhibits a rougher surface texture and higher tensile strength, while annealed titanium offers improved formability and reduced residual stress. These core differences impact the selection of titanium for applications requiring flexibility versus those needing maximum durability and surface quality.

Mechanical Strength Comparison: Annealed vs Mill Finished Titanium

Annealed titanium exhibits lower mechanical strength compared to mill finished titanium due to the heat treatment process that softens the metal to enhance ductility and formability. Mill finished titanium retains higher tensile strength and yield strength, as it has not undergone heat treatment, preserving its original hardness and structural integrity. The choice between annealed and mill finished titanium depends on application requirements for strength versus flexibility.

Surface Characteristics: Annealed Versus Mill Finished Finishes

Annealed titanium exhibits a smooth, uniform surface with reduced internal stresses compared to mill finished titanium, which often retains rough, uneven textures from the initial rolling process. The annealing process refines the grain structure and enhances surface homogeneity, improving corrosion resistance and machinability. In contrast, mill finished titanium surfaces may require additional processing to achieve comparable smoothness and performance characteristics.

Corrosion Resistance: How Annealing Impacts Titanium

Annealed titanium exhibits superior corrosion resistance compared to mill finished titanium due to the heat treatment process that reduces internal stresses and homogenizes the microstructure. This annealing process stabilizes the oxide layer on the surface, enhancing its protective properties against oxidation and chemical attack in aggressive environments. As a result, annealed titanium is preferred for applications requiring long-term durability in corrosive settings such as marine, chemical processing, and biomedical industries.

Applications: When to Use Annealed Titanium or Mill Finished Titanium

Annealed titanium offers enhanced ductility and formability, making it ideal for applications requiring complex shaping, such as aerospace components and medical implants. Mill finished titanium retains its high strength and hardness, suitable for structural parts and environments demanding wear resistance and corrosion protection. Choosing between annealed and mill finished titanium depends on the balance between flexibility and strength needed for specific industrial or biomedical applications.

Machinability and Workability: Which is Easier to Process?

Annealed titanium offers superior machinability and workability compared to mill finished titanium due to its softer and more ductile microstructure, which reduces tool wear and allows for easier cutting, shaping, and forming processes. Mill finished titanium, being harder and more brittle, poses greater challenges during machining, often requiring specialized tools and slower feed rates to avoid damage. For manufacturing applications demanding precision and efficiency, annealed titanium is generally preferred because it enhances processing speed and reduces production costs.

Cost Factors: Annealed Titanium vs Mill Finished Titanium

Annealed titanium incurs higher production costs due to the additional heat treatment process that enhances its ductility and machinability, making it more suitable for precision applications. Mill finished titanium, while less expensive, lacks this treatment and may exhibit residual stresses and lower mechanical properties. The choice between annealed and mill finished titanium often balances cost efficiency with performance requirements, impacting overall project budgets.

Choosing the Right Titanium Finish for Industrial Projects

Annealed titanium offers enhanced ductility and improved machinability, making it ideal for applications requiring forming or welding in industrial projects. Mill finished titanium retains its original hardness and surface texture, providing superior corrosion resistance and structural strength for heavy-duty or load-bearing components. Selecting between annealed and mill finished titanium depends on specific project demands such as flexibility versus durability and environmental exposure conditions.

Annealed Titanium vs Mill Finished Titanium Infographic

materialdif.com

materialdif.com