Titanium mesh offers superior biocompatibility and corrosion resistance compared to stainless steel mesh, making it ideal for long-term medical implants in pet surgeries. Its lightweight yet durable structure reduces the risk of rejection and enhances healing, whereas stainless mesh may cause allergic reactions or degrade over time. Titanium's non-magnetic properties also ensure compatibility with imaging techniques, providing better postoperative monitoring for pets.

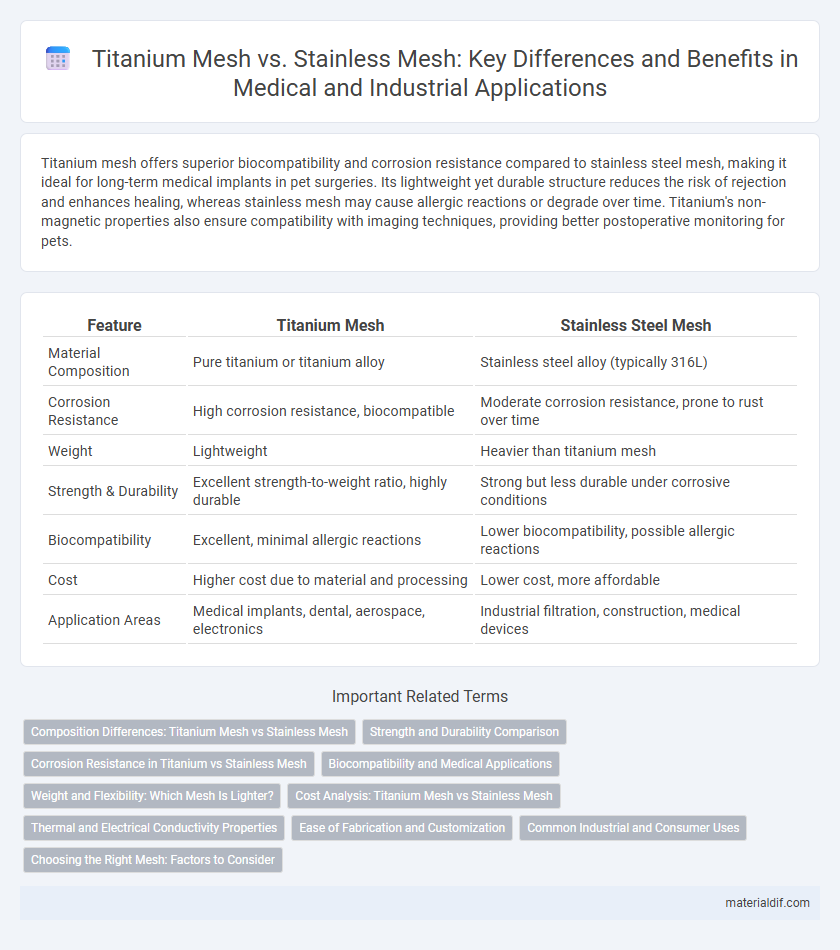

Table of Comparison

| Feature | Titanium Mesh | Stainless Steel Mesh |

|---|---|---|

| Material Composition | Pure titanium or titanium alloy | Stainless steel alloy (typically 316L) |

| Corrosion Resistance | High corrosion resistance, biocompatible | Moderate corrosion resistance, prone to rust over time |

| Weight | Lightweight | Heavier than titanium mesh |

| Strength & Durability | Excellent strength-to-weight ratio, highly durable | Strong but less durable under corrosive conditions |

| Biocompatibility | Excellent, minimal allergic reactions | Lower biocompatibility, possible allergic reactions |

| Cost | Higher cost due to material and processing | Lower cost, more affordable |

| Application Areas | Medical implants, dental, aerospace, electronics | Industrial filtration, construction, medical devices |

Composition Differences: Titanium Mesh vs Stainless Mesh

Titanium mesh consists primarily of titanium, an element known for its high strength-to-weight ratio, corrosion resistance, and biocompatibility, making it ideal for medical implants and aerospace applications. Stainless mesh, primarily composed of iron, chromium (usually 10-30%), and nickel, offers excellent corrosion resistance and durability but is denser and heavier than titanium. The key compositional difference lies in titanium's pure metal or alloy base versus stainless steel's multi-element alloy structure, influencing mechanical properties and applications.

Strength and Durability Comparison

Titanium mesh offers superior strength-to-weight ratio compared to stainless steel mesh, making it ideal for applications requiring lightweight yet robust materials. Its corrosion resistance significantly enhances durability, especially in harsh environments where stainless steel may degrade over time. Titanium also maintains structural integrity under cyclic stresses better than stainless steel, ensuring longer lifespan and reliability.

Corrosion Resistance in Titanium vs Stainless Mesh

Titanium mesh exhibits superior corrosion resistance compared to stainless steel mesh due to its stable oxide film that protects against oxidation and various chemical attacks. Unlike stainless steel, which can suffer from pitting and crevice corrosion in chloride-rich environments, titanium maintains its integrity even in aggressive conditions such as marine or industrial atmospheres. This inherent corrosion resistance makes titanium mesh ideal for long-term applications requiring durability and biocompatibility.

Biocompatibility and Medical Applications

Titanium mesh exhibits superior biocompatibility compared to stainless steel mesh, minimizing inflammatory responses and promoting osseointegration in medical implants. It is preferred in reconstructive surgeries and craniofacial applications due to its corrosion resistance and lightweight properties that reduce patient discomfort. Stainless steel mesh, while cost-effective, has a higher risk of allergic reactions and is less commonly used in long-term implantations.

Weight and Flexibility: Which Mesh Is Lighter?

Titanium mesh is significantly lighter than stainless steel mesh, offering superior flexibility ideal for medical and structural applications where weight reduction is crucial. Stainless steel mesh, while stronger and more rigid, adds considerable weight and lacks the same degree of malleability, making titanium the preferred choice in scenarios requiring both durability and lightweight properties. The lower density of titanium (approximately 4.5 g/cm3) compared to stainless steel (around 8 g/cm3) directly impacts its weight advantage and performance in flexible mesh designs.

Cost Analysis: Titanium Mesh vs Stainless Mesh

Titanium mesh typically costs significantly more than stainless steel mesh due to its superior biocompatibility, corrosion resistance, and lightweight properties, which justify the higher initial investment in medical and industrial applications. Stainless steel mesh remains a cost-effective alternative, offering adequate strength and durability but lacking the enhanced longevity and reduced risk of rejection associated with titanium. When evaluating long-term expenses, titanium mesh may result in lower overall costs by minimizing complications, replacements, and maintenance compared to stainless steel mesh.

Thermal and Electrical Conductivity Properties

Titanium mesh exhibits significantly lower thermal and electrical conductivity compared to stainless steel mesh, making it less efficient at heat and electrical transfer. The thermal conductivity of titanium is approximately 22 W/m*K, whereas stainless steel typically ranges from 15 to 25 W/m*K depending on the alloy composition, with some grades slightly outperforming titanium in conductivity. Titanium's lower electrical conductivity, around 2.38% IACS (International Annealed Copper Standard), contrasts with stainless steel's higher variability, generally between 1-10% IACS, influencing their suitability in applications requiring precise thermal or electrical management.

Ease of Fabrication and Customization

Titanium mesh offers superior ease of fabrication due to its lightweight nature and excellent malleability, allowing precise shaping and customization for complex medical implants. Stainless steel mesh, while strong and durable, tends to be heavier and less flexible, making detailed customization more challenging. The corrosion resistance of titanium further enhances its suitability for personalized surgical applications compared to stainless steel.

Common Industrial and Consumer Uses

Titanium mesh offers superior corrosion resistance and biocompatibility, making it ideal for aerospace components, medical implants, and high-performance filtration systems. Stainless steel mesh is favored in food processing, chemical screening, and general industrial filtration due to its strength and cost-effectiveness. Both materials serve critical roles in filtration and structural applications, with titanium preferred in environments requiring enhanced durability and stainless steel in more economical or less corrosive conditions.

Choosing the Right Mesh: Factors to Consider

Choosing between titanium mesh and stainless steel mesh depends on factors such as biocompatibility, corrosion resistance, and mechanical strength. Titanium mesh offers superior corrosion resistance and lighter weight, making it ideal for medical implants and cranial reconstruction, while stainless steel mesh provides greater rigidity and cost-effectiveness for structural applications. Evaluating the specific environmental conditions, load requirements, and potential for allergic reactions is crucial in selecting the appropriate mesh material.

Titanium Mesh vs Stainless Mesh Infographic

materialdif.com

materialdif.com