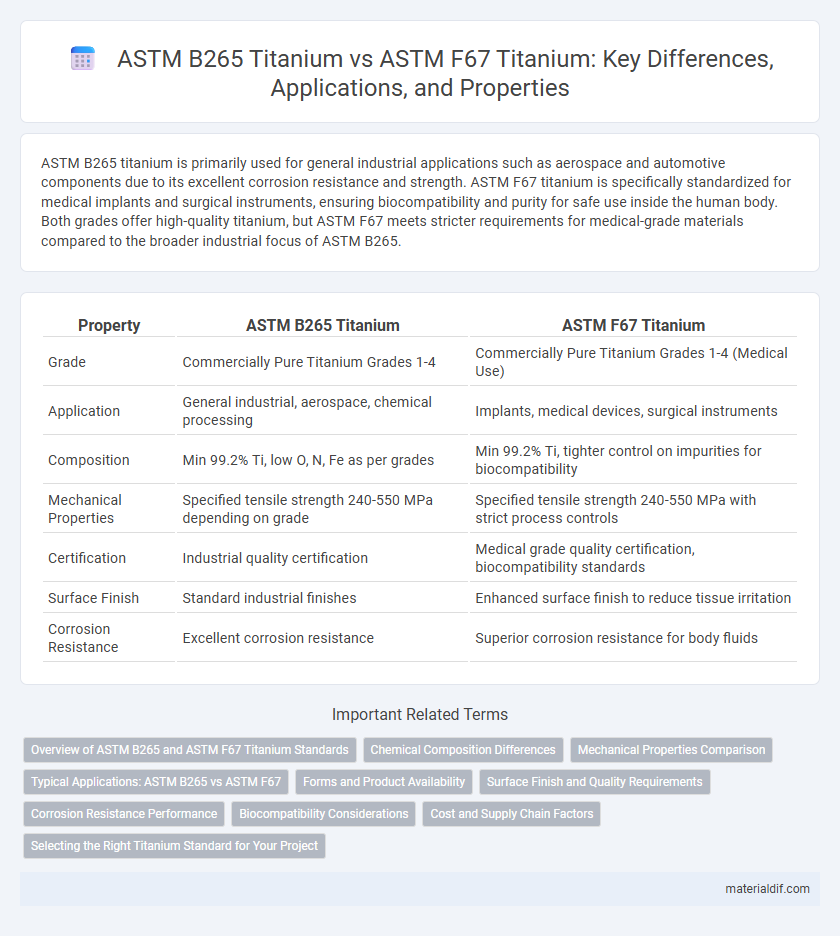

ASTM B265 titanium is primarily used for general industrial applications such as aerospace and automotive components due to its excellent corrosion resistance and strength. ASTM F67 titanium is specifically standardized for medical implants and surgical instruments, ensuring biocompatibility and purity for safe use inside the human body. Both grades offer high-quality titanium, but ASTM F67 meets stricter requirements for medical-grade materials compared to the broader industrial focus of ASTM B265.

Table of Comparison

| Property | ASTM B265 Titanium | ASTM F67 Titanium |

|---|---|---|

| Grade | Commercially Pure Titanium Grades 1-4 | Commercially Pure Titanium Grades 1-4 (Medical Use) |

| Application | General industrial, aerospace, chemical processing | Implants, medical devices, surgical instruments |

| Composition | Min 99.2% Ti, low O, N, Fe as per grades | Min 99.2% Ti, tighter control on impurities for biocompatibility |

| Mechanical Properties | Specified tensile strength 240-550 MPa depending on grade | Specified tensile strength 240-550 MPa with strict process controls |

| Certification | Industrial quality certification | Medical grade quality certification, biocompatibility standards |

| Surface Finish | Standard industrial finishes | Enhanced surface finish to reduce tissue irritation |

| Corrosion Resistance | Excellent corrosion resistance | Superior corrosion resistance for body fluids |

Overview of ASTM B265 and ASTM F67 Titanium Standards

ASTM B265 specifies requirements for titanium and titanium-alloy seamless and welded plate, sheet, and strip for general use, emphasizing chemical composition, mechanical properties, and dimensional tolerances suitable for industries such as aerospace and chemical processing. ASTM F67 focuses on unalloyed titanium for surgical implant applications, detailing stringent requirements for biocompatibility, purity, tensile strength, and hardness to ensure safety and performance in medical environments. Both standards address titanium quality but diverge significantly in application-specific criteria, with ASTM B265 tailored for structural and industrial purposes and ASTM F67 designed to meet rigorous medical implant standards.

Chemical Composition Differences

ASTM B265 titanium primarily covers titanium and titanium alloy products for general engineering use, featuring a range of grades with varying aluminum and vanadium content, such as Grade 2 with a maximum of 0.30% oxygen and 0.08% nitrogen for enhanced strength. ASTM F67 titanium is specifically designated for surgical implant applications, typically using Grade 1 titanium, which has a lower maximum iron content of 0.20% and oxygen limit of 0.18% to improve biocompatibility and corrosion resistance. The key chemical composition differences lie in ASTM F67's tighter limits on impurity elements to meet medical-grade purity standards, whereas ASTM B265 allows broader composition ranges suited for industrial purposes.

Mechanical Properties Comparison

ASTM B265 titanium primarily addresses general-purpose titanium sheet and plate with tensile strengths typically ranging from 50 ksi to 120 ksi, suitable for structural applications. ASTM F67 titanium is a titanium unalloyed for surgical implant applications, featuring a minimum tensile strength of about 55 ksi, optimized for biocompatibility and consistent mechanical properties critical in medical environments. While both grades share similar corrosion resistance and ductility, ASTM F67 emphasizes yield strength and elongation to meet stringent biomedical implant performance standards, contrasting with the broader industrial focus of ASTM B265.

Typical Applications: ASTM B265 vs ASTM F67

ASTM B265 titanium is primarily used in aerospace, industrial, and marine applications due to its excellent strength and corrosion resistance, making it suitable for structural components, pressure vessels, and heat exchangers. ASTM F67 titanium, on the other hand, is specifically designed for medical implants and surgical devices, emphasizing biocompatibility and purity to ensure safe interaction with human tissue. The distinction in typical applications reflects ASTM B265's focus on engineering durability versus ASTM F67's critical role in biomedical environments.

Forms and Product Availability

ASTM B265 titanium primarily comes in sheet, plate, strip, and coil forms, making it ideal for aerospace, industrial, and commercial applications requiring various thicknesses and widths. ASTM F67 titanium is specified for surgical implants and is available mainly as bar, wire, and forging stock, emphasizing biocompatibility and precise mechanical properties for medical device manufacturing. Product availability for ASTM B265 titanium is broader due to its diverse industrial use, while ASTM F67 titanium has more specialized distribution channels catering to the medical and dental sectors.

Surface Finish and Quality Requirements

ASTM B265 Titanium specifies comprehensive surface finish criteria with a smooth, uniform texture suitable for general industrial applications, while ASTM F67 Titanium mandates stricter surface finish and quality requirements tailored for medical implants, emphasizing biocompatibility and minimal surface imperfections. The F67 standard enforces rigorous inspection to ensure the absence of microdefects, enhancing corrosion resistance and fatigue strength critical for surgical use. In contrast, B265 focuses on mechanical properties and structural integrity, allowing a broader range of surface finishes aligned with aerospace and automotive demands.

Corrosion Resistance Performance

ASTM B265 titanium, typically used in industrial applications, offers excellent corrosion resistance in both oxidizing and reducing environments due to its commercially pure composition. ASTM F67 titanium, specifically designed for surgical implants, demonstrates superior corrosion resistance in physiological environments, resisting pitting and crevice corrosion critical for biocompatibility. The enhanced corrosion resistance of ASTM F67 titanium is attributed to its stricter chemical composition and higher purity standards compared to ASTM B265 titanium.

Biocompatibility Considerations

ASTM B265 titanium is primarily used for aerospace applications and offers excellent corrosion resistance but lacks strict certification for biocompatibility, making it less suitable for medical implants. ASTM F67 titanium is specifically certified for implant-grade purity with rigorous biocompatibility standards, ensuring safe and stable integration with human tissue. The enhanced control over interstitial elements and chemical composition in ASTM F67 titanium directly supports improved cellular response and reduced risk of adverse biological reactions.

Cost and Supply Chain Factors

ASTM B265 titanium typically offers lower cost options due to its broader range of grades and less stringent purity requirements compared to ASTM F67 titanium, which is specifically produced for medical and aerospace applications with higher quality control standards. Supply chain reliability for ASTM F67 titanium can be more limited and costly, as it involves specialized processing and certification to meet stringent biocompatibility and mechanical properties. Manufacturers often face longer lead times and higher procurement expenses for ASTM F67, while ASTM B265 titanium benefits from more widespread availability and cost-effective sourcing.

Selecting the Right Titanium Standard for Your Project

ASTM B265 Titanium specifies titanium and titanium alloy plates, sheets, and strips used in general engineering and architectural applications, offering excellent corrosion resistance and strength for diverse industrial tasks. ASTM F67 Titanium is specifically designed for unalloyed titanium forming surgical implants and medical devices, ensuring biocompatibility and strict purity standards. Selecting the right titanium standard depends on the project's requirements: ASTM B265 for structural or industrial applications and ASTM F67 for medical-grade, implant-quality titanium.

ASTM B265 Titanium vs ASTM F67 Titanium Infographic

materialdif.com

materialdif.com