Medical grade titanium offers superior biocompatibility and corrosion resistance compared to industrial grade titanium, making it ideal for pet implants and medical devices. Its purity and controlled manufacturing processes ensure it is safe for prolonged contact with animal tissues. Industrial grade titanium, while strong and durable, may contain impurities unsuitable for medical applications in pets.

Table of Comparison

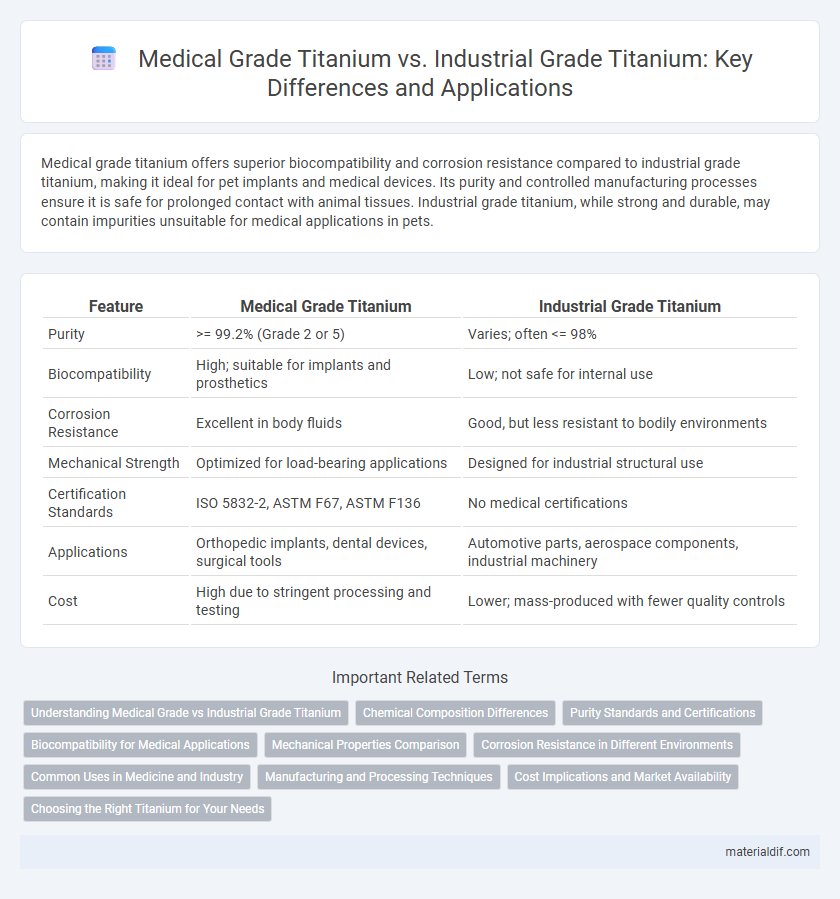

| Feature | Medical Grade Titanium | Industrial Grade Titanium |

|---|---|---|

| Purity | >= 99.2% (Grade 2 or 5) | Varies; often <= 98% |

| Biocompatibility | High; suitable for implants and prosthetics | Low; not safe for internal use |

| Corrosion Resistance | Excellent in body fluids | Good, but less resistant to bodily environments |

| Mechanical Strength | Optimized for load-bearing applications | Designed for industrial structural use |

| Certification Standards | ISO 5832-2, ASTM F67, ASTM F136 | No medical certifications |

| Applications | Orthopedic implants, dental devices, surgical tools | Automotive parts, aerospace components, industrial machinery |

| Cost | High due to stringent processing and testing | Lower; mass-produced with fewer quality controls |

Understanding Medical Grade vs Industrial Grade Titanium

Medical grade titanium is specifically manufactured to meet rigorous biocompatibility standards, ensuring it is safe for use in implants and surgical instruments, while industrial grade titanium is designed primarily for strength and corrosion resistance in applications such as aerospace and automotive parts. The alloy composition and purity levels differ significantly, with medical grade titanium typically being commercially pure (CP) or titanium alloyed with small amounts of aluminum and vanadium (Ti-6Al-4V), minimizing the risk of allergic reactions or toxicity in the human body. Certification and testing for medical grade titanium include strict controls on contaminants and mechanical properties to guarantee performance and safety, unlike industrial grade titanium which prioritizes physical performance over biocompatibility.

Chemical Composition Differences

Medical grade titanium primarily consists of commercially pure titanium or titanium alloys such as Ti-6Al-4V, characterized by strict limits on aluminum and vanadium content to ensure biocompatibility and corrosion resistance. Industrial grade titanium often contains higher levels of impurities like iron, oxygen, and carbon, which can compromise mechanical properties and increase the risk of adverse reactions in biological environments. The precise chemical composition standards in medical grade titanium guarantee safety and performance in implants and surgical instruments, distinguishing it sharply from industrial grade titanium used in aerospace or automotive applications.

Purity Standards and Certifications

Medical grade titanium is characterized by its superior purity standards, typically containing at least 99.2% titanium, ensuring biocompatibility and resistance to corrosion for safe use in implants and surgical instruments. This grade complies with strict certifications such as ASTM F67 and ISO 5832, which validate its suitability for medical applications. In contrast, industrial grade titanium has lower purity levels, often includes more alloying elements, and lacks the rigorous certifications required for medical use, making it suitable primarily for aerospace or automotive components.

Biocompatibility for Medical Applications

Medical grade titanium exhibits superior biocompatibility compared to industrial grade titanium, making it ideal for implants and prosthetics due to its non-toxic, hypoallergenic properties. Its controlled alloy composition and purity reduce the risk of adverse tissue reactions, ensuring long-term stability within the human body. Industrial grade titanium lacks the stringent quality and biocompatibility standards required for medical applications, leading to potential complications when used in biomedical devices.

Mechanical Properties Comparison

Medical grade titanium, primarily Ti-6Al-4V alloy, exhibits superior tensile strength of around 900 MPa and exceptional corrosion resistance, critical for implant durability and biocompatibility. Industrial grade titanium typically has lower tensile strength, near 500 MPa, and reduced purity, making it less suitable for long-term bodily implantation but ideal for aerospace and automotive applications. The enhanced fatigue resistance and lower elastic modulus of medical grade titanium minimize stress shielding, ensuring better mechanical compatibility with human bone.

Corrosion Resistance in Different Environments

Medical grade titanium exhibits superior corrosion resistance compared to industrial grade titanium due to its high purity and controlled alloy composition, making it ideal for use in bodily environments such as implants and surgical instruments. Industrial grade titanium, often containing more impurities and alloying elements, is more susceptible to corrosion when exposed to harsh chemicals, saltwater, and industrial atmospheres. This enhanced corrosion resistance in medical grade titanium significantly reduces the risk of toxicity and implant failure within the human body.

Common Uses in Medicine and Industry

Medical grade titanium, characterized by its biocompatibility and corrosion resistance, is primarily used in orthopedic implants, dental prosthetics, and surgical instruments. Industrial grade titanium, while less pure, is commonly utilized in aerospace components, automotive parts, and chemical processing equipment due to its strength and resistance to extreme environments. The distinction in purity and mechanical properties dictates their specialized applications across medical and industrial sectors.

Manufacturing and Processing Techniques

Medical grade titanium undergoes precise manufacturing processes such as vacuum arc remelting and cold working to achieve superior biocompatibility, corrosion resistance, and mechanical strength essential for implants and surgical instruments. Industrial grade titanium typically involves less rigorous processing methods, including standard casting and forging, resulting in higher impurity levels and reduced consistency in microstructure. Advanced techniques like electron beam melting and hot isostatic pressing are critical in medical-grade titanium production to ensure purity and performance under physiological conditions.

Cost Implications and Market Availability

Medical grade titanium, primarily alloyed as Ti-6Al-4V ELI (Extra Low Interstitial), incurs higher costs due to rigorous purification standards and biocompatibility certifications essential for implants and surgical instruments. In contrast, industrial grade titanium, with fewer purity requirements and broader alloy variations, is more affordable and widely available for manufacturing, aerospace, and automotive applications. The medical sector's strict regulatory compliance limits supply sources, impacting market availability and driving up prices compared to mass-produced industrial titanium alloys.

Choosing the Right Titanium for Your Needs

Medical grade titanium, specifically ASTM F136 and ASTM F67, offers superior biocompatibility, corrosion resistance, and strength, making it ideal for implants and surgical instruments. Industrial grade titanium, while still strong and corrosion-resistant, lacks the stringent purity and certification requirements necessary for medical applications. Choosing the right titanium depends on the intended use; medical grade is essential for health-related purposes, whereas industrial grade suffices for aerospace, automotive, and manufacturing needs.

Medical Grade Titanium vs Industrial Grade Titanium Infographic

materialdif.com

materialdif.com