Cold-rolled titanium offers superior surface finish and tighter tolerances compared to hot-rolled titanium, making it ideal for precision applications and aesthetic purposes. Hot-rolled titanium provides enhanced strength and toughness due to its recrystallized grain structure, suitable for structural components subjected to high stress. Choosing between cold-rolled and hot-rolled titanium depends on the specific requirements of mechanical properties and surface quality in the intended use.

Table of Comparison

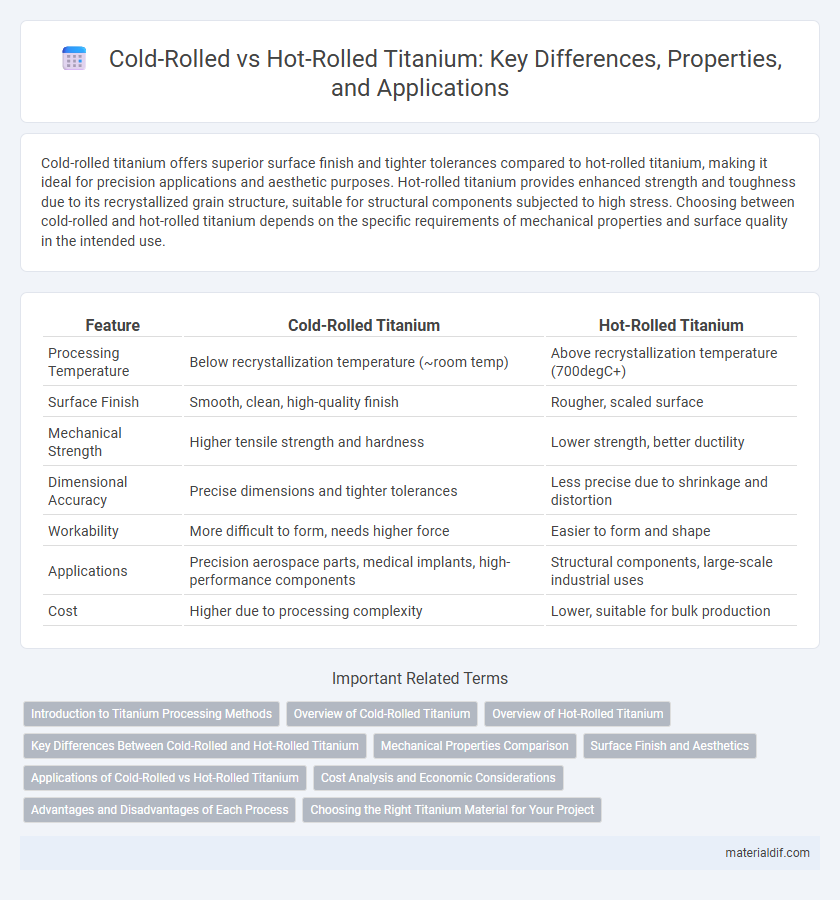

| Feature | Cold-Rolled Titanium | Hot-Rolled Titanium |

|---|---|---|

| Processing Temperature | Below recrystallization temperature (~room temp) | Above recrystallization temperature (700degC+) |

| Surface Finish | Smooth, clean, high-quality finish | Rougher, scaled surface |

| Mechanical Strength | Higher tensile strength and hardness | Lower strength, better ductility |

| Dimensional Accuracy | Precise dimensions and tighter tolerances | Less precise due to shrinkage and distortion |

| Workability | More difficult to form, needs higher force | Easier to form and shape |

| Applications | Precision aerospace parts, medical implants, high-performance components | Structural components, large-scale industrial uses |

| Cost | Higher due to processing complexity | Lower, suitable for bulk production |

Introduction to Titanium Processing Methods

Cold-rolled titanium offers enhanced surface finish and precise dimensional tolerances compared to hot-rolled titanium, making it ideal for applications requiring high strength and corrosion resistance. Hot-rolled titanium undergoes processing at high temperatures, resulting in thicker, coarser grain structures suitable for structural components where formability is critical. Understanding these processing methods helps optimize titanium's mechanical properties for aerospace, medical, and chemical industries.

Overview of Cold-Rolled Titanium

Cold-rolled titanium features enhanced surface finish, tighter dimensional tolerances, and increased strength compared to hot-rolled titanium due to the deformation process occurring below its recrystallization temperature. This method results in improved mechanical properties, making cold-rolled titanium ideal for aerospace, medical, and high-performance industrial applications. The precise control over thickness and surface quality also allows for superior corrosion resistance and better fatigue strength.

Overview of Hot-Rolled Titanium

Hot-rolled titanium is processed at high temperatures above the metal's recrystallization point, enhancing its ductility and reducing internal stresses for improved formability. This rolling method produces titanium sheets and plates with a rougher surface finish and more uniform grain structure compared to cold-rolled titanium. Its applications favor structural components requiring strength and toughness over aesthetic surface quality, commonly used in aerospace, automotive, and industrial manufacturing.

Key Differences Between Cold-Rolled and Hot-Rolled Titanium

Cold-rolled titanium features a smoother surface finish and tighter dimensional tolerances compared to hot-rolled titanium, which undergoes processing at high temperatures resulting in a rougher texture and looser tolerances. The cold rolling process enhances mechanical properties such as yield strength and hardness due to strain hardening, whereas hot-rolled titanium offers better ductility and easier machinability. Selection between cold-rolled and hot-rolled titanium depends on application requirements for surface quality, strength, and formability.

Mechanical Properties Comparison

Cold-rolled titanium exhibits higher tensile strength and improved surface finish compared to hot-rolled titanium due to work hardening during the cold rolling process. Hot-rolled titanium offers enhanced ductility and toughness, making it more suitable for applications requiring deformation without cracking. Mechanical properties such as yield strength typically range from 620 to 930 MPa in cold-rolled titanium, while hot-rolled variants generally show lower strength but greater elongation percentages.

Surface Finish and Aesthetics

Cold-rolled titanium offers a smoother, more refined surface finish with enhanced dimensional accuracy, making it ideal for applications requiring superior aesthetics and corrosion resistance. Hot-rolled titanium displays a rougher, scaled surface with more pronounced grain structure, resulting in a matte finish that is less visually appealing but suitable for heavy fabrication. The choice between cold-rolled and hot-rolled titanium directly impacts the final appearance, with cold-rolled titanium preferred for architectural and decorative uses due to its polished, clean look.

Applications of Cold-Rolled vs Hot-Rolled Titanium

Cold-rolled titanium offers superior surface finish and precise dimensional tolerances, making it ideal for aerospace components, medical implants, and high-performance automotive parts where corrosion resistance and strength are critical. Hot-rolled titanium, characterized by its enhanced ductility and grain structure, is commonly used in structural applications, industrial equipment, and chemical processing where toughness and formability outweigh the need for fine surface detail. The choice between cold-rolled and hot-rolled titanium depends on specific application requirements such as mechanical properties, surface quality, and fabrication processes.

Cost Analysis and Economic Considerations

Cold-rolled titanium typically incurs higher production costs due to increased labor intensity and slower processing times, impacting overall pricing compared to hot-rolled titanium. Hot-rolled titanium offers cost efficiency through faster manufacturing and lower energy consumption, making it economically preferable for large-scale industrial applications. Selection between the two processes hinges on balancing budget constraints with the desired mechanical properties and surface finish.

Advantages and Disadvantages of Each Process

Cold-rolled titanium offers superior surface finish, increased strength, and tighter dimensional tolerances, making it ideal for aerospace and medical applications where precision is critical. Hot-rolled titanium, while less expensive and more malleable due to higher processing temperatures, may exhibit coarser surface finishes, greater dimensional variability, and lower strength compared to cold-rolled counterparts. The choice between cold and hot rolling depends on balancing cost, mechanical properties, and surface quality requirements for specific industrial uses.

Choosing the Right Titanium Material for Your Project

Cold-rolled titanium offers superior surface finish, tighter tolerances, and increased strength due to work hardening, making it ideal for precision applications like aerospace components and medical devices. Hot-rolled titanium, produced at high temperatures, provides enhanced ductility and is more suitable for large structural parts where formability and toughness are critical. Selecting the right titanium material depends on balancing mechanical properties, surface requirements, and project-specific performance criteria to ensure optimal durability and functionality.

Cold-Rolled Titanium vs Hot-Rolled Titanium Infographic

materialdif.com

materialdif.com