Anodized titanium features a protective oxide layer that enhances corrosion resistance and allows for vibrant color options, making it ideal for pet accessories exposed to varying conditions. Non-anodized titanium offers natural durability and strength without added surface treatments but may be more susceptible to scratches and wear over time. Choosing anodized titanium provides both aesthetic appeal and prolonged lifespan for pet products compared to non-anodized variants.

Table of Comparison

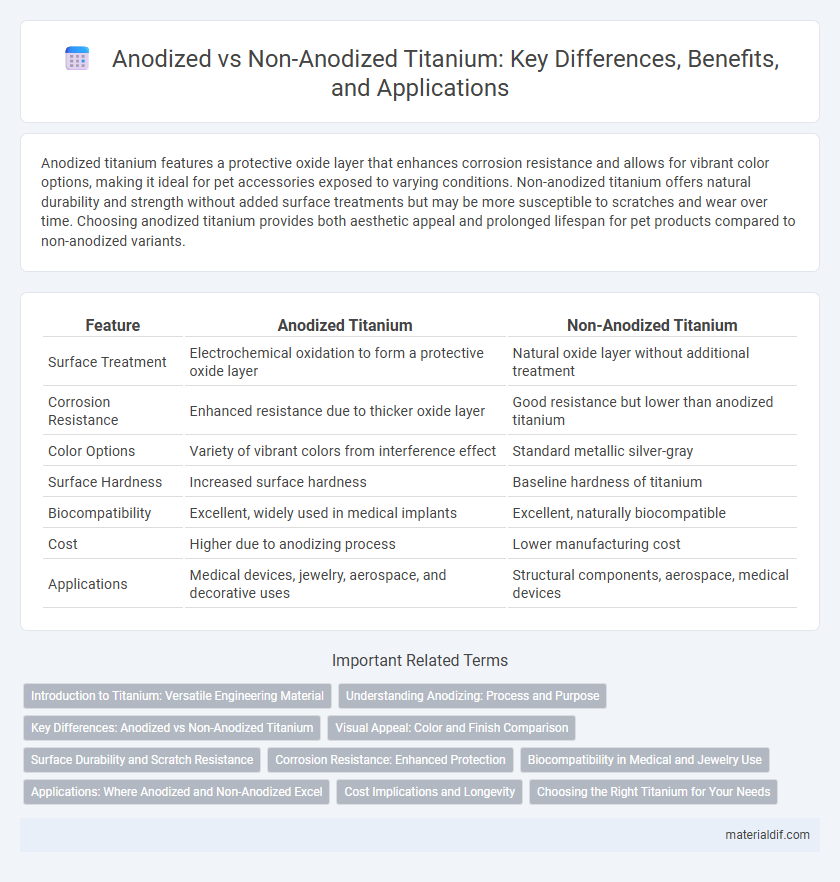

| Feature | Anodized Titanium | Non-Anodized Titanium |

|---|---|---|

| Surface Treatment | Electrochemical oxidation to form a protective oxide layer | Natural oxide layer without additional treatment |

| Corrosion Resistance | Enhanced resistance due to thicker oxide layer | Good resistance but lower than anodized titanium |

| Color Options | Variety of vibrant colors from interference effect | Standard metallic silver-gray |

| Surface Hardness | Increased surface hardness | Baseline hardness of titanium |

| Biocompatibility | Excellent, widely used in medical implants | Excellent, naturally biocompatible |

| Cost | Higher due to anodizing process | Lower manufacturing cost |

| Applications | Medical devices, jewelry, aerospace, and decorative uses | Structural components, aerospace, medical devices |

Introduction to Titanium: Versatile Engineering Material

Titanium is a lightweight, high-strength metal widely used in aerospace, medical devices, and automotive industries due to its corrosion resistance and biocompatibility. Anodized titanium undergoes an electrochemical process that enhances surface hardness, increases corrosion resistance, and allows for vibrant color finishes, making it ideal for aesthetic and protective applications. Non-anodized titanium retains its natural metallic appearance with excellent strength and corrosion resistance, preferred where surface modification is unnecessary or where machining and welding are involved.

Understanding Anodizing: Process and Purpose

Anodized titanium undergoes an electrochemical process that increases the thickness of the natural oxide layer on its surface, enhancing corrosion resistance and durability. This anodic layer also provides better wear resistance and enables a variety of vibrant color finishes without using dyes or paints. Non-anodized titanium maintains its raw metallic appearance but lacks the enhanced protective and aesthetic properties achieved through anodizing, making it more susceptible to surface wear and oxidation over time.

Key Differences: Anodized vs Non-Anodized Titanium

Anodized titanium undergoes an electrochemical process that enhances its corrosion resistance, surface hardness, and aesthetic appearance by forming a durable oxide layer. Non-anodized titanium retains its natural metallic finish but lacks the additional protective and color-enhancing properties of anodization. The key differences between anodized and non-anodized titanium lie in surface durability, color variety, and resistance to wear and oxidation.

Visual Appeal: Color and Finish Comparison

Anodized titanium exhibits a vibrant range of colors created through an electrochemical process that alters its oxide layer, enhancing visual appeal and allowing customization from subtle golds to vivid blues and purples. Non-anodized titanium retains its natural metallic silver-gray finish, offering a sleek, understated look with a matte or polished surface depending on the manufacturing process. The anodization not only adds aesthetic variety but also improves corrosion resistance, making anodized titanium favored in applications where distinct coloration and durability are essential.

Surface Durability and Scratch Resistance

Anodized titanium features a thicker oxide layer that significantly enhances surface durability and scratch resistance compared to non-anodized titanium, making it more resistant to wear and corrosion. The anodization process creates a protective barrier that prevents surface degradation from environmental factors, extending the material's lifespan in demanding applications. Non-anodized titanium, while inherently strong, is more susceptible to surface scratches and oxidation without this additional treatment.

Corrosion Resistance: Enhanced Protection

Anodized titanium exhibits significantly improved corrosion resistance compared to non-anodized titanium due to the formation of a dense, protective oxide layer that prevents oxidation and surface degradation. This anodic coating enhances durability in harsh environments, including exposure to saltwater, acidic substances, and industrial chemicals. Non-anodized titanium lacks this enhanced oxide film, making it more vulnerable to corrosion and surface wear over time.

Biocompatibility in Medical and Jewelry Use

Anodized titanium enhances biocompatibility by forming a thicker oxide layer that improves corrosion resistance and reduces the risk of allergic reactions in both medical implants and jewelry. Non-anodized titanium, while naturally biocompatible and corrosion-resistant, offers a thinner oxide layer that may be less protective in highly reactive environments. The anodization process allows for controlled surface modifications, promoting better cell adhesion and minimizing metal ion release, which is crucial for long-term implantation and skin contact.

Applications: Where Anodized and Non-Anodized Excel

Anodized titanium excels in applications requiring enhanced corrosion resistance and aesthetic customization, such as aerospace components and medical implants, where color-coding and surface protection are critical. Non-anodized titanium is preferred in structural applications like automotive parts and industrial machinery due to its raw strength and natural oxide layer. Both forms offer unique advantages: anodized titanium enhances durability and visual appeal, while non-anodized titanium provides consistent mechanical performance in demanding environments.

Cost Implications and Longevity

Anodized titanium typically incurs higher upfront costs due to the additional electrochemical surface treatment that enhances corrosion resistance and surface hardness. Non-anodized titanium, while more affordable initially, may require more frequent maintenance or replacement over time because it lacks the protective oxide layer. The longevity of anodized titanium often justifies its cost by reducing long-term expenses associated with wear, corrosion, and surface degradation.

Choosing the Right Titanium for Your Needs

Anodized titanium offers enhanced corrosion resistance, increased surface hardness, and customizable color options, making it ideal for applications requiring durability and aesthetic appeal. Non-anodized titanium provides excellent baseline strength, biocompatibility, and lightweight properties suited for medical implants and aerospace components where surface modification is unnecessary. Selecting the right titanium depends on factors like environmental exposure, mechanical demands, and desired visual characteristics.

Anodized Titanium vs Non-Anodized Titanium Infographic

materialdif.com

materialdif.com