SPF Titanium features a unique manufacturing process that enhances purity and structural integrity compared to conventional formed titanium. This advanced technique results in superior mechanical strength and corrosion resistance, making SPF Titanium ideal for high-performance applications. The refined grain structure in SPF Titanium also contributes to improved fatigue resistance, extending the material's lifespan in demanding environments.

Table of Comparison

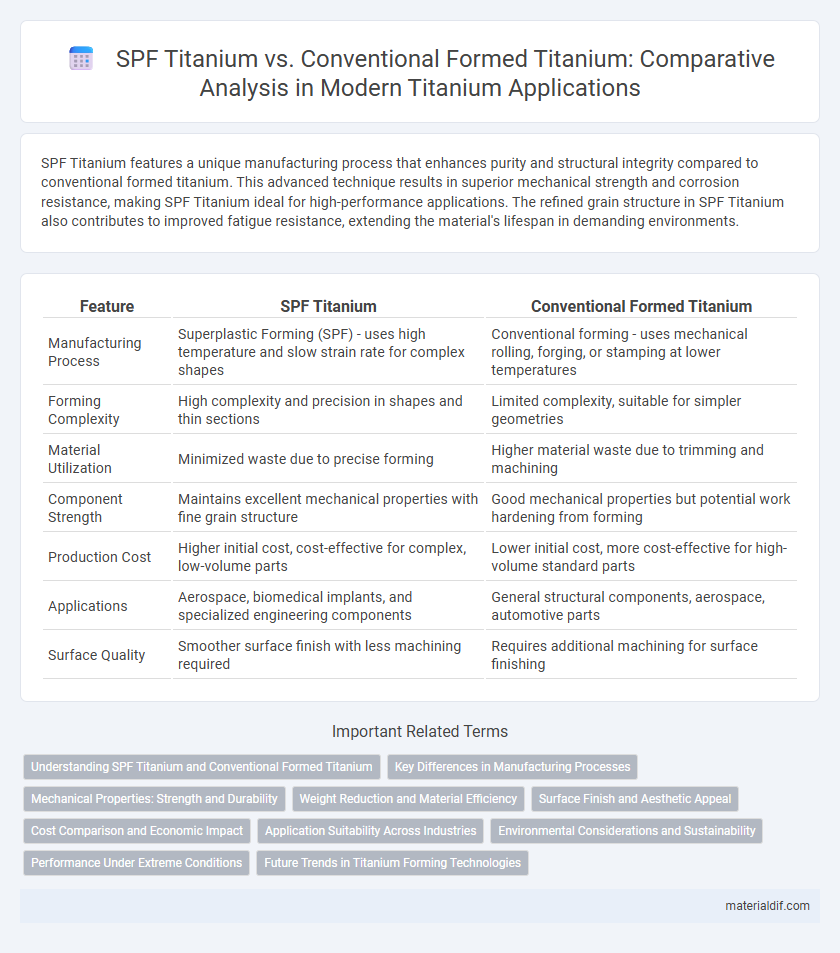

| Feature | SPF Titanium | Conventional Formed Titanium |

|---|---|---|

| Manufacturing Process | Superplastic Forming (SPF) - uses high temperature and slow strain rate for complex shapes | Conventional forming - uses mechanical rolling, forging, or stamping at lower temperatures |

| Forming Complexity | High complexity and precision in shapes and thin sections | Limited complexity, suitable for simpler geometries |

| Material Utilization | Minimized waste due to precise forming | Higher material waste due to trimming and machining |

| Component Strength | Maintains excellent mechanical properties with fine grain structure | Good mechanical properties but potential work hardening from forming |

| Production Cost | Higher initial cost, cost-effective for complex, low-volume parts | Lower initial cost, more cost-effective for high-volume standard parts |

| Applications | Aerospace, biomedical implants, and specialized engineering components | General structural components, aerospace, automotive parts |

| Surface Quality | Smoother surface finish with less machining required | Requires additional machining for surface finishing |

Understanding SPF Titanium and Conventional Formed Titanium

SPF titanium, or Superplastic Formed titanium, undergoes a unique process where the material is heated and stretched to achieve complex shapes with enhanced mechanical properties, offering superior formability compared to conventional formed titanium. Conventional formed titanium typically involves techniques such as rolling, forging, or bending at lower temperatures, which may limit its ability to produce intricate geometries without compromising strength. Understanding the differences between SPF titanium and conventional formed titanium is crucial for industries like aerospace and medical devices, where precision, lightweight, and structural integrity are paramount.

Key Differences in Manufacturing Processes

SPF Titanium, or Superplastic Formed Titanium, utilizes high-temperature superplasticity to shape complex components with uniform properties and minimal residual stress, unlike Conventional Formed Titanium which relies on mechanical deformation methods such as rolling or forging. The SPF process allows for intricate designs and reduced material waste by stretching titanium sheets into intricate molds, whereas conventional forming techniques involve multiple steps and more extensive machining. These manufacturing distinctions result in SPF Titanium offering enhanced precision and superior mechanical performance in aerospace and medical applications.

Mechanical Properties: Strength and Durability

SPF Titanium exhibits superior mechanical properties compared to conventional formed titanium, offering enhanced tensile strength and fatigue resistance due to its refined microstructure achieved through superplastic forming. Its durability under cyclic loading conditions surpasses that of traditional formed titanium, making it ideal for aerospace and automotive applications requiring high performance. The improved grain boundary cohesion in SPF Titanium contributes significantly to its elevated strength and long-term structural integrity.

Weight Reduction and Material Efficiency

SPF titanium offers significant weight reduction compared to conventional formed titanium by enabling near-net-shape manufacturing, which minimizes material waste and machining time. This process enhances material efficiency through precise control of microstructure, resulting in superior strength-to-weight ratios ideal for aerospace and automotive applications. Utilizing SPF titanium optimizes resource utilization and reduces production costs while maintaining structural integrity.

Surface Finish and Aesthetic Appeal

SPF Titanium exhibits a finer surface finish compared to Conventional Formed Titanium, resulting from its powder metallurgy production process that reduces surface irregularities and porosity. This enhanced surface texture contributes significantly to a superior aesthetic appeal, making SPF Titanium ideal for applications where visual quality is critical. The smoother and more uniform appearance of SPF Titanium also enhances its corrosion resistance, further improving its longevity and visual performance.

Cost Comparison and Economic Impact

SPF Titanium, produced through powder metallurgy, typically offers lower material waste and reduced machining costs compared to conventional formed titanium, leading to overall cost savings in manufacturing. The economic impact of SPF Titanium includes improved yield and shorter production cycles, which enhance supply chain efficiency and reduce inventory expenses. While initial investment in SPF technology may be higher, the long-term cost benefits and resource optimization make it a competitive choice over traditional titanium forming methods.

Application Suitability Across Industries

SPF Titanium offers superior mechanical properties and enhanced corrosion resistance compared to conventional formed titanium, making it ideal for high-performance aerospace, medical implants, and chemical processing industries. Its fine, uniform microstructure ensures better fatigue resistance and strength-to-weight ratio, crucial for demanding applications such as aircraft structural components and biomedical devices. Conventional formed titanium remains suitable for less critical applications in automotive parts and architectural elements where cost-efficiency is prioritized.

Environmental Considerations and Sustainability

SPF titanium, produced through Spark Plasma Sintering, offers superior energy efficiency and lower carbon emissions compared to conventional formed titanium, which involves extensive melting and forging processes. The additive manufacturing nature of SPF titanium reduces material waste significantly, enhancing resource sustainability in titanium production. These environmental advantages position SPF titanium as a more eco-friendly alternative within aerospace and biomedical industries where titanium demand is high.

Performance Under Extreme Conditions

SPF Titanium exhibits superior performance under extreme conditions compared to conventional formed titanium due to its fine-grained microstructure and enhanced mechanical properties. This material demonstrates higher strength, improved fatigue resistance, and better corrosion resistance in high-temperature and harsh environmental applications. Industries such as aerospace and chemical processing benefit from SPF Titanium's reliability and durability where conventional formed titanium may fail.

Future Trends in Titanium Forming Technologies

Emerging trends in titanium forming technologies emphasize advanced methods such as additive manufacturing and high-precision SPF (Superplastic Forming) Titanium, which significantly enhance material performance and reduce production costs compared to conventional formed titanium. SPF Titanium offers superior grain refinement and improved mechanical properties, enabling its use in aerospace, automotive, and biomedical industries where lightweight and high-strength components are critical. Future developments aim to integrate real-time process monitoring and AI-driven optimization to further increase efficiency and quality in titanium forming applications.

SPF Titanium vs Conventional Formed Titanium Infographic

materialdif.com

materialdif.com