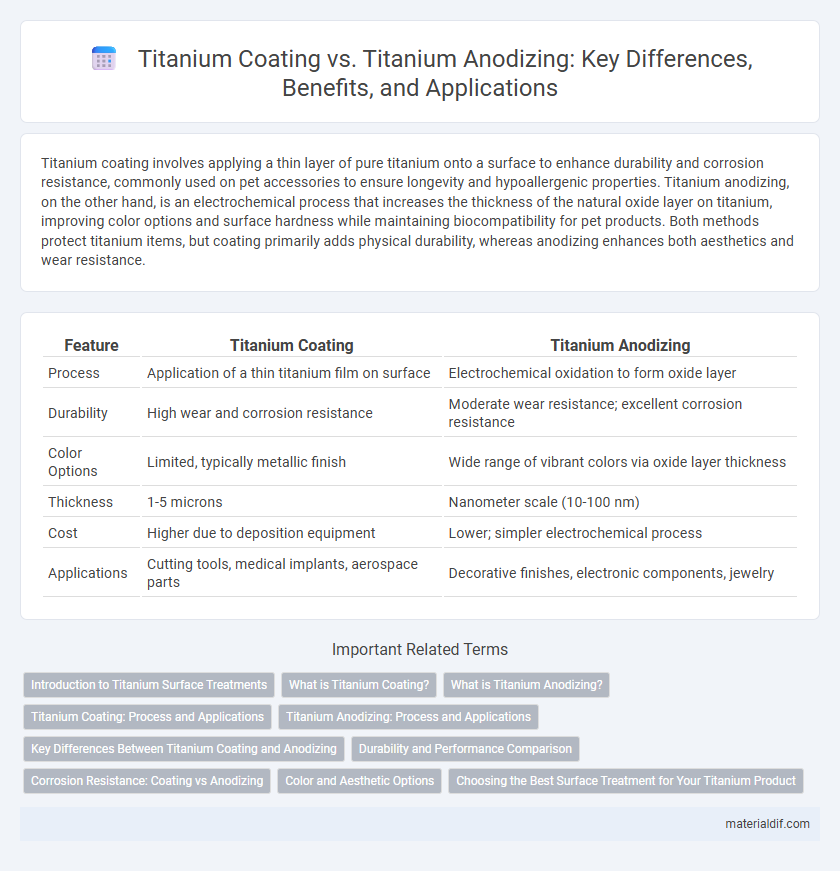

Titanium coating involves applying a thin layer of pure titanium onto a surface to enhance durability and corrosion resistance, commonly used on pet accessories to ensure longevity and hypoallergenic properties. Titanium anodizing, on the other hand, is an electrochemical process that increases the thickness of the natural oxide layer on titanium, improving color options and surface hardness while maintaining biocompatibility for pet products. Both methods protect titanium items, but coating primarily adds physical durability, whereas anodizing enhances both aesthetics and wear resistance.

Table of Comparison

| Feature | Titanium Coating | Titanium Anodizing |

|---|---|---|

| Process | Application of a thin titanium film on surface | Electrochemical oxidation to form oxide layer |

| Durability | High wear and corrosion resistance | Moderate wear resistance; excellent corrosion resistance |

| Color Options | Limited, typically metallic finish | Wide range of vibrant colors via oxide layer thickness |

| Thickness | 1-5 microns | Nanometer scale (10-100 nm) |

| Cost | Higher due to deposition equipment | Lower; simpler electrochemical process |

| Applications | Cutting tools, medical implants, aerospace parts | Decorative finishes, electronic components, jewelry |

Introduction to Titanium Surface Treatments

Titanium coating involves applying a protective layer of titanium or titanium compounds onto a substrate to enhance durability, corrosion resistance, and aesthetic appeal. Titanium anodizing is an electrochemical process that thicken the natural oxide layer on the titanium surface, improving hardness, wear resistance, and color options through controlled oxidation. Both surface treatments are essential for optimizing titanium's performance in aerospace, medical implants, and industrial applications.

What is Titanium Coating?

Titanium coating involves applying a thin layer of titanium or titanium-based materials onto a substrate to enhance corrosion resistance, wear durability, and biocompatibility. This process typically uses physical vapor deposition (PVD) or chemical vapor deposition (CVD) techniques, resulting in a dense, uniform film that protects underlying materials from oxidative and mechanical damage. Titanium coating is favored in aerospace, medical implants, and industrial tools for its ability to improve surface hardness and extend the lifespan of components.

What is Titanium Anodizing?

Titanium anodizing is an electrochemical process that enhances the metal's surface by forming a durable oxide layer, improving corrosion resistance and allowing for vibrant color finishes. This technique alters the titanium's surface structure without adding extra material, unlike titanium coating which involves applying a separate layer. Anodizing titanium increases hardness and wear resistance while maintaining the metal's biocompatibility and lightweight properties.

Titanium Coating: Process and Applications

Titanium coating involves applying a thin layer of titanium or titanium-based compounds onto a substrate using techniques such as physical vapor deposition (PVD) or chemical vapor deposition (CVD), enhancing corrosion resistance, hardness, and wear properties. This process is widely utilized in aerospace, medical implants, and industrial tools where superior durability and biocompatibility are critical. Titanium coatings contribute to extending component life and performance, especially in aggressive environments requiring high strength-to-weight ratios.

Titanium Anodizing: Process and Applications

Titanium anodizing involves an electrochemical process that enhances the metal's surface by forming a durable oxide layer, increasing corrosion resistance and color customization. This method is widely used in aerospace, medical implants, and decorative applications due to its ability to produce vibrant, wear-resistant finishes without compromising the metal's strength. Compared to titanium coating, anodizing maintains the base metal's integrity while offering environmentally friendly and cost-effective surface engineering solutions.

Key Differences Between Titanium Coating and Anodizing

Titanium coating involves applying a physical or chemical layer, such as PVD or CVD, onto the titanium surface to enhance hardness, corrosion resistance, and aesthetics, whereas titanium anodizing electrochemically modifies the surface oxide layer to improve corrosion resistance and create vibrant coloration. Coatings tend to increase surface thickness and provide protection against wear and scratches, while anodizing primarily alters the oxide layer's thickness without adding substantial physical material. Titanium coating offers a broader range of customizable surface properties, while anodizing is more environmentally friendly and typically used for color-coding and mild corrosion resistance enhancement.

Durability and Performance Comparison

Titanium coating offers superior wear resistance and corrosion protection by forming a dense, hard surface layer, enhancing its durability in extreme environments. Titanium anodizing creates a controlled oxide layer that improves surface hardness and corrosion resistance while allowing color customization, though it is generally thinner and less impact-resistant than coatings. Performance-wise, coated titanium excels in high-friction applications, whereas anodized titanium is preferred for aesthetic and moderate durability uses.

Corrosion Resistance: Coating vs Anodizing

Titanium coating provides a physical barrier that enhances corrosion resistance by preventing direct exposure of the metal to environmental elements, making it suitable for harsh conditions. Titanium anodizing creates a controlled oxide layer on the surface, significantly improving corrosion resistance by increasing the natural passivation of the metal while maintaining its lightweight and strength properties. Compared to coatings, anodizing offers a more durable and integral corrosion protection layer that resists wear and degradation without peeling or flaking.

Color and Aesthetic Options

Titanium coating provides a wide range of vibrant, durable color options through physical vapor deposition, resulting in a smooth, metallic finish that enhances corrosion resistance. Titanium anodizing alters the oxide layer on the surface, producing iridescent colors that shift with light angles and offer a unique, natural aesthetic without adding material thickness. Both techniques enhance titanium's visual appeal, but anodizing emphasizes subtle, color-changing effects while coating delivers consistent, vivid hues.

Choosing the Best Surface Treatment for Your Titanium Product

Titanium coating offers enhanced wear resistance and corrosion protection by applying a thin, durable layer, ideal for industrial and medical applications requiring robust surface performance. Titanium anodizing improves surface hardness and aesthetic appeal while increasing oxide layer thickness for better corrosion resistance, making it suitable for decorative and lightweight applications. Selecting the best surface treatment depends on the specific functional requirements, such as durability needs and visual finish preferences, ensuring optimal performance for your titanium product.

Titanium Coating vs Titanium Anodizing Infographic

materialdif.com

materialdif.com