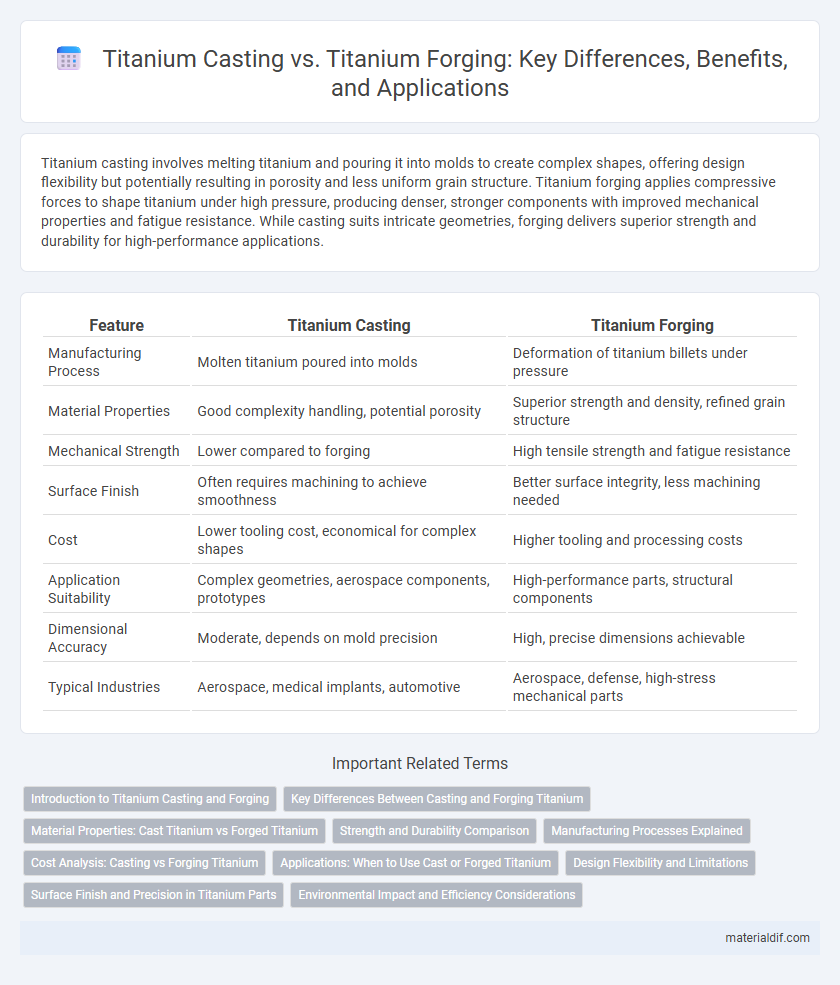

Titanium casting involves melting titanium and pouring it into molds to create complex shapes, offering design flexibility but potentially resulting in porosity and less uniform grain structure. Titanium forging applies compressive forces to shape titanium under high pressure, producing denser, stronger components with improved mechanical properties and fatigue resistance. While casting suits intricate geometries, forging delivers superior strength and durability for high-performance applications.

Table of Comparison

| Feature | Titanium Casting | Titanium Forging |

|---|---|---|

| Manufacturing Process | Molten titanium poured into molds | Deformation of titanium billets under pressure |

| Material Properties | Good complexity handling, potential porosity | Superior strength and density, refined grain structure |

| Mechanical Strength | Lower compared to forging | High tensile strength and fatigue resistance |

| Surface Finish | Often requires machining to achieve smoothness | Better surface integrity, less machining needed |

| Cost | Lower tooling cost, economical for complex shapes | Higher tooling and processing costs |

| Application Suitability | Complex geometries, aerospace components, prototypes | High-performance parts, structural components |

| Dimensional Accuracy | Moderate, depends on mold precision | High, precise dimensions achievable |

| Typical Industries | Aerospace, medical implants, automotive | Aerospace, defense, high-stress mechanical parts |

Introduction to Titanium Casting and Forging

Titanium casting involves pouring molten titanium into molds to create complex shapes with fine details, ideal for intricate components. Titanium forging applies high-pressure deformation to solid titanium billets, improving grain structure and mechanical properties for enhanced strength and durability. Both processes optimize titanium's lightweight, corrosion-resistant characteristics for aerospace, medical, and automotive industries.

Key Differences Between Casting and Forging Titanium

Titanium casting involves pouring molten titanium into molds to form complex shapes, allowing for intricate designs but often resulting in slightly lower mechanical strength due to potential porosity and grain structure inconsistencies. Titanium forging, on the other hand, applies compressive forces to shape solid titanium billets, producing parts with superior strength, toughness, and fatigue resistance thanks to refined grain alignment and reduced internal defects. Key differences include casting's capability for complex geometries at lower cost versus forging's enhanced mechanical properties ideal for high-performance aerospace and medical applications.

Material Properties: Cast Titanium vs Forged Titanium

Cast titanium exhibits a more complex microstructure with increased porosity and inclusions compared to forged titanium, resulting in lower tensile strength and fatigue resistance. Forged titanium offers a refined grain structure and superior mechanical properties, including higher yield strength, toughness, and fatigue endurance. Material density and corrosion resistance remain comparable, but forging enhances overall durability for critical aerospace and medical applications.

Strength and Durability Comparison

Titanium forging produces components with superior strength and durability due to its refined grain structure and reduced porosity, making it ideal for critical aerospace and medical applications. In contrast, titanium casting allows for complex shapes but often results in lower mechanical properties and increased susceptibility to defects such as shrinkage and porosity. Forged titanium parts exhibit higher fatigue resistance and toughness compared to castings, enhancing their performance in high-stress environments.

Manufacturing Processes Explained

Titanium casting involves pouring molten titanium into molds to create complex shapes with minimal machining, offering cost-effective production for intricate designs. Titanium forging uses high-pressure deformation of solid titanium billets, resulting in superior mechanical properties and enhanced structural integrity. Manufacturing choices depend on application requirements, with casting favored for complex geometries and forging preferred for high-strength components.

Cost Analysis: Casting vs Forging Titanium

Titanium casting generally offers lower initial tooling costs and greater design flexibility, making it cost-effective for complex geometries and low to medium production volumes. Titanium forging involves higher upfront expenses due to specialized equipment and labor intensity but results in superior mechanical properties and material efficiency, beneficial for high-performance applications. Considering total cost of ownership, casting provides economic advantages in prototyping and custom parts, while forging delivers long-term value through enhanced durability and reduced scrap rates in large-scale production.

Applications: When to Use Cast or Forged Titanium

Cast titanium is ideal for complex shapes and intricate designs commonly required in aerospace components where weight reduction and corrosion resistance are critical. Forged titanium delivers superior mechanical strength and fatigue resistance, making it the preferred choice for high-stress applications such as aircraft landing gears and medical implants. Selecting cast or forged titanium depends on balancing design complexity, performance requirements, and production volume in industries like aerospace, automotive, and biomedical engineering.

Design Flexibility and Limitations

Titanium casting offers greater design flexibility, allowing the creation of complex shapes, intricate geometries, and internal cavities that are challenging to achieve with forging. Forging provides superior mechanical properties and grain structure alignment but is limited in the complexity of shapes it can produce, typically restricted to simpler, more uniform designs. Choosing between casting and forging depends on balancing design complexity needs with strength and performance requirements in titanium components.

Surface Finish and Precision in Titanium Parts

Titanium casting typically results in a rougher surface finish requiring additional machining to achieve tight tolerances, whereas titanium forging produces parts with superior surface quality and higher dimensional accuracy due to the controlled deformation process. Forged titanium components exhibit enhanced mechanical properties and consistency, making them preferable for applications demanding precision and minimal post-processing. Casting is more flexible for complex shapes but generally less precise, while forging ensures a smoother surface finish and closer adherence to design specifications.

Environmental Impact and Efficiency Considerations

Titanium casting generally consumes more energy and produces higher emissions due to melting and pouring processes, whereas titanium forging offers greater material efficiency by reducing waste and enhancing mechanical properties through deformation. Forging minimizes scrap and often requires fewer processing steps, leading to lower overall environmental impact despite higher initial energy input. Selecting titanium forging over casting helps improve sustainability in aerospace and medical industries by maximizing resource utilization and decreasing carbon footprint.

Titanium Casting vs Titanium Forging Infographic

materialdif.com

materialdif.com