Unalloyed titanium offers exceptional corrosion resistance and biocompatibility, making it ideal for medical implants and aerospace applications. Titanium alloys enhance mechanical strength and durability while maintaining lightweight properties, suitable for high-performance engineering. Choosing between unalloyed titanium and titanium alloy depends on balancing pure corrosion resistance against structural requirements.

Table of Comparison

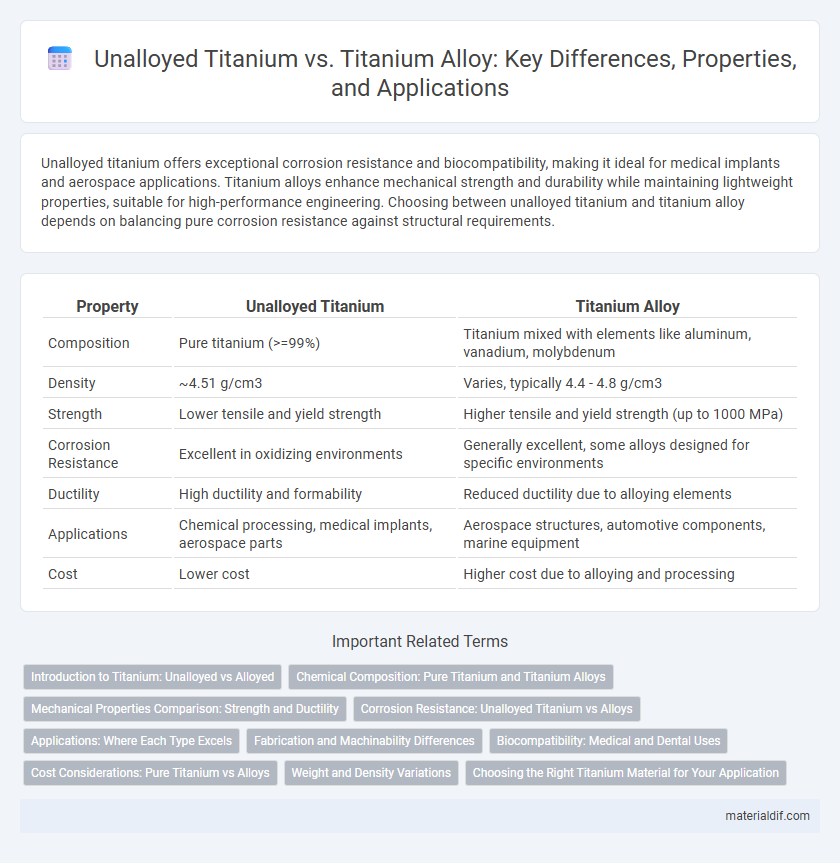

| Property | Unalloyed Titanium | Titanium Alloy |

|---|---|---|

| Composition | Pure titanium (>=99%) | Titanium mixed with elements like aluminum, vanadium, molybdenum |

| Density | ~4.51 g/cm3 | Varies, typically 4.4 - 4.8 g/cm3 |

| Strength | Lower tensile and yield strength | Higher tensile and yield strength (up to 1000 MPa) |

| Corrosion Resistance | Excellent in oxidizing environments | Generally excellent, some alloys designed for specific environments |

| Ductility | High ductility and formability | Reduced ductility due to alloying elements |

| Applications | Chemical processing, medical implants, aerospace parts | Aerospace structures, automotive components, marine equipment |

| Cost | Lower cost | Higher cost due to alloying and processing |

Introduction to Titanium: Unalloyed vs Alloyed

Unalloyed titanium consists of nearly pure titanium, offering excellent corrosion resistance, high strength-to-weight ratio, and biocompatibility, making it ideal for aerospace, medical, and chemical applications. Titanium alloys combine titanium with elements like aluminum, vanadium, or molybdenum to enhance mechanical properties such as increased hardness, improved fatigue resistance, and greater thermal stability. While unalloyed titanium excels in environments demanding purity and corrosion resistance, titanium alloys are preferred in structural and high-stress applications requiring superior strength and durability.

Chemical Composition: Pure Titanium and Titanium Alloys

Unalloyed titanium consists nearly entirely of pure titanium metal with a chemical composition exceeding 99.2% titanium, resulting in exceptional corrosion resistance and biocompatibility. Titanium alloys incorporate elements such as aluminum, vanadium, molybdenum, and iron, enhancing mechanical strength, temperature resistance, and structural performance for aerospace and medical applications. The precise chemical makeup of titanium alloys varies to balance ductility and hardness, optimizing them for specific industrial needs.

Mechanical Properties Comparison: Strength and Ductility

Unalloyed titanium exhibits lower tensile strength, typically around 240 MPa, but offers superior ductility with elongation rates exceeding 20%, making it highly formable. Titanium alloys, such as Ti-6Al-4V, provide significantly higher strength values reaching up to 900 MPa, though their ductility decreases to approximately 10-15%. The trade-off between strength and ductility in these materials influences their selection for aerospace, biomedical, and industrial applications.

Corrosion Resistance: Unalloyed Titanium vs Alloys

Unalloyed titanium exhibits superior corrosion resistance due to its stable oxide film, which protects against a wide range of aggressive environments including seawater and chlorine-containing solutions. Titanium alloys, while offering enhanced mechanical strength, may have slightly reduced corrosion resistance depending on the alloying elements such as aluminum, vanadium, or molybdenum. In highly corrosive applications, unalloyed titanium is preferred for its exceptional inertness and longevity.

Applications: Where Each Type Excels

Unalloyed titanium excels in aerospace and medical implants due to its exceptional corrosion resistance and biocompatibility, making it ideal for environments requiring purity and strength without compromise. Titanium alloys, enhanced with elements like aluminum and vanadium, dominate automotive, military, and industrial applications by offering superior strength-to-weight ratios and improved performance under high stress and temperature conditions. Both materials serve critical roles, with unalloyed titanium preferred for chemical resistance and alloyed titanium favored for structural and high-stress applications.

Fabrication and Machinability Differences

Unalloyed titanium offers superior corrosion resistance and is easier to form due to its lower strength and higher ductility, making it ideal for applications requiring complex shapes through processes like bending and welding. Titanium alloys, with added elements like aluminum and vanadium, exhibit higher strength and hardness but present challenges in machining, necessitating specialized cutting tools and techniques to reduce tool wear and maintain precision. The increased strength in titanium alloys impacts fabrication speed and cost, often requiring slower machining parameters compared to unalloyed titanium for optimal results.

Biocompatibility: Medical and Dental Uses

Unalloyed titanium exhibits excellent biocompatibility, making it highly suitable for medical and dental implants due to its ability to integrate well with bone tissue and resist corrosion. Titanium alloys, such as Ti-6Al-4V, offer enhanced mechanical strength while maintaining good biocompatibility, supporting load-bearing applications like orthopedic implants and dental prosthetics. Both forms minimize immune response and promote osseointegration, essential for long-term implant success in biomedical engineering.

Cost Considerations: Pure Titanium vs Alloys

Unalloyed titanium typically costs less than titanium alloys due to its simpler extraction and processing requirements, making it a cost-effective option for applications where strength and corrosion resistance needs are moderate. Titanium alloys, such as Ti-6Al-4V, involve additional alloying elements like aluminum and vanadium, increasing production expenses but enhancing mechanical properties and performance in demanding environments. Evaluating the total cost of ownership involves balancing initial material costs against performance benefits, durability, and maintenance savings over the product lifecycle.

Weight and Density Variations

Unalloyed titanium has a density of approximately 4.51 g/cm3, making it lightweight yet strong, while titanium alloys typically range from 4.4 to 4.8 g/cm3 depending on the alloying elements. The addition of elements such as aluminum, vanadium, and molybdenum increases density slightly but significantly enhances strength and corrosion resistance. Weight variations are crucial in aerospace and automotive applications where titanium alloys offer an optimal balance of low density and high mechanical performance compared to unalloyed titanium.

Choosing the Right Titanium Material for Your Application

Unalloyed titanium offers exceptional corrosion resistance and excellent strength-to-weight ratio, making it ideal for applications requiring high purity and biocompatibility, such as medical implants and chemical processing equipment. Titanium alloys, enhanced with elements like aluminum and vanadium, provide significantly increased strength and improved mechanical properties suitable for aerospace, automotive, and structural components. Selecting the right titanium material depends on factors such as load requirements, environmental conditions, and fabrication processes to ensure optimal performance and durability.

Unalloyed Titanium vs Titanium Alloy Infographic

materialdif.com

materialdif.com