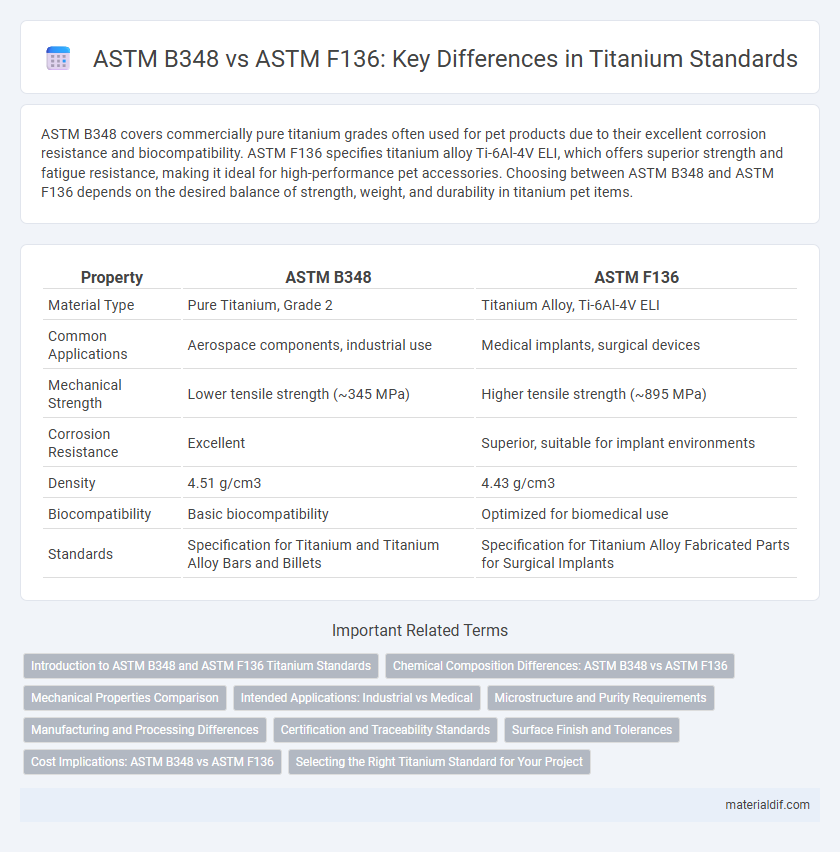

ASTM B348 covers commercially pure titanium grades often used for pet products due to their excellent corrosion resistance and biocompatibility. ASTM F136 specifies titanium alloy Ti-6Al-4V ELI, which offers superior strength and fatigue resistance, making it ideal for high-performance pet accessories. Choosing between ASTM B348 and ASTM F136 depends on the desired balance of strength, weight, and durability in titanium pet items.

Table of Comparison

| Property | ASTM B348 | ASTM F136 |

|---|---|---|

| Material Type | Pure Titanium, Grade 2 | Titanium Alloy, Ti-6Al-4V ELI |

| Common Applications | Aerospace components, industrial use | Medical implants, surgical devices |

| Mechanical Strength | Lower tensile strength (~345 MPa) | Higher tensile strength (~895 MPa) |

| Corrosion Resistance | Excellent | Superior, suitable for implant environments |

| Density | 4.51 g/cm3 | 4.43 g/cm3 |

| Biocompatibility | Basic biocompatibility | Optimized for biomedical use |

| Standards | Specification for Titanium and Titanium Alloy Bars and Billets | Specification for Titanium Alloy Fabricated Parts for Surgical Implants |

Introduction to ASTM B348 and ASTM F136 Titanium Standards

ASTM B348 specifies the requirements for titanium and titanium alloy bars and billets used in aerospace, industrial, and commercial applications, emphasizing chemical composition, mechanical properties, and dimensional tolerances. ASTM F136 pertains specifically to titanium alloy (Ti-6Al-4V ELI) forged bars and shapes intended for surgical implants, focusing on biocompatibility, microstructure, and stringent mechanical property standards. Both standards ensure high-quality titanium materials but target different industries--ASTM B348 for general engineering and ASTM F136 for medical device manufacturing.

Chemical Composition Differences: ASTM B348 vs ASTM F136

ASTM B348 specifies commercially pure titanium grades, primarily focusing on titanium content above 99%, with minimal impurities like iron and oxygen tightly controlled to maintain ductility and corrosion resistance. ASTM F136, a titanium alloy standard for medical implants, mandates specific additions of aluminum (around 6%) and vanadium (around 4%) to enhance strength and fatigue resistance, absent in ASTM B348. The chemical composition differences distinctly influence material properties, where ASTM B348 favors purity for general industrial use, contrasting with ASTM F136's alloyed formulation optimized for biocompatibility and mechanical performance in biomedical applications.

Mechanical Properties Comparison

ASTM B348 titanium typically features a tensile strength of approximately 620 MPa and yield strength near 480 MPa, making it suitable for structural applications requiring moderate strength. ASTM F136 titanium, a titanium alloy (Ti-6Al-4V ELI), exhibits enhanced mechanical properties with tensile strength around 900 MPa and yield strength up to 830 MPa, offering superior strength and fatigue resistance. The significant difference in mechanical properties between ASTM B348 (commercially pure titanium) and ASTM F136 (medical-grade alloy) influences their respective uses in aerospace versus biomedical implants.

Intended Applications: Industrial vs Medical

ASTM B348 titanium is primarily used in industrial applications such as aerospace, automotive, and marine sectors due to its excellent strength, corrosion resistance, and formability. ASTM F136 titanium is specifically designed for medical implants, including orthopedic devices and surgical instruments, offering superior biocompatibility and fatigue resistance. The distinct specifications ensure ASTM B348 supports structural performance needs while ASTM F136 meets stringent medical safety and performance standards.

Microstructure and Purity Requirements

ASTM B348 covers commercially pure titanium grades with a microstructure primarily consisting of alpha-phase titanium, emphasizing minimal impurities to ensure high corrosion resistance and ductility. ASTM F136 specifies titanium-6Al-4V ELI alloy with a dual-phase microstructure of alpha and beta phases, designed for enhanced mechanical strength and fracture toughness in biomedical implants. Purity requirements in ASTM B348 demand low levels of interstitials such as oxygen, nitrogen, and iron, while ASTM F136 imposes stricter controls on trace elements to optimize biocompatibility and fatigue resistance.

Manufacturing and Processing Differences

ASTM B348 specifies commercially pure titanium grades used primarily in forgings and mill products, emphasizing high corrosion resistance and excellent weldability with straightforward manufacturing processes such as forging, rolling, and extrusion. ASTM F136 covers titanium alloy Ti-6Al-4V ELI, typically utilized in complex medical implants requiring precision machining, strict heat treatment, and processing controls to ensure biocompatibility and mechanical integrity. Manufacturing ASTM B348 titanium involves less stringent thermal and mechanical processing compared to ASTM F136, which demands rigorous processing protocols including vacuum melting, hot isostatic pressing, and precise aging treatments to achieve enhanced strength and fatigue resistance.

Certification and Traceability Standards

ASTM B348 specifies certification and traceability standards for commercially pure titanium, ensuring material composition and mechanical properties meet strict industry requirements. ASTM F136 focuses on titanium alloy (Ti-6Al-4V ELI) used primarily in medical implants, enforcing rigorous traceability and quality control through detailed documentation and batch testing. Both standards mandate comprehensive certification processes to guarantee the authenticity, grade, and traceability of titanium materials throughout the supply chain.

Surface Finish and Tolerances

ASTM B348 specifies the standard for commercially pure titanium and titanium alloy bars, emphasizing precise surface finish with a maximum roughness average (Ra) of 32 microinches and tight dimensional tolerances suitable for machining and industrial applications. ASTM F136 focuses on titanium alloy implants, demanding a superior surface finish with an Ra typically below 16 microinches to minimize tissue irritation, alongside stricter geometric tolerances to ensure biocompatibility and mechanical integrity in medical devices. The critical difference between ASTM B348 and ASTM F136 lies in the latter's enhanced surface and tolerance requirements tailored for implant-grade titanium, ensuring optimal performance and safety in biomedical applications.

Cost Implications: ASTM B348 vs ASTM F136

ASTM B348 titanium, commonly used in industrial applications, offers a lower cost option compared to ASTM F136, which is specifically designed for high-performance medical implants. The manufacturing process and strict biocompatibility standards of ASTM F136 increase production expenses, driving up its overall price. Choosing ASTM B348 can reduce material costs for non-medical uses without compromising essential titanium properties.

Selecting the Right Titanium Standard for Your Project

ASTM B348 specifies the requirements for commercially pure titanium and titanium alloy bars, billets, and forgings, primarily used in aerospace and industrial applications where high strength and corrosion resistance are crucial. ASTM F136 focuses on titanium alloy implants, particularly Ti-6Al-4V ELI, designed for medical devices requiring biocompatibility and fatigue resistance. Selecting the right titanium standard hinges on the project's application demands--ASTM B348 suits structural and mechanical uses, while ASTM F136 is essential for biomedical implants ensuring safety and performance.

ASTM B348 vs ASTM F136 Infographic

materialdif.com

materialdif.com